Wood Stove with Heat Exchanger: Difference between revisions

Jump to navigation

Jump to search

| Line 37: | Line 37: | ||

BTU Requirement Formula = cubic footage * .133 * fahrenheit degree change = ~200,000 btu | BTU Requirement Formula = cubic footage * .133 * fahrenheit degree change = ~200,000 btu | ||

=Expert Review= | |||

*October 26, 2012 - from Tom Kimmel, President, [[SACA]] - This is basically a good design. What you want is a large volume so you can load it with large chunks or logs of wood. The Startup Flue Pipe is a very good design detail. It can be used for startup and then again as a by-pass if the heat exchangers are getting too hot for any reason. There is one addition I would make and that is to put a thick piece of steel in there about 2 or 3 inches below the top of the stove. It will be a few inches shorter than the stove with the space being near the front door. What you want to do is to get a complete burn of the smoke by making it go up from the fire, run along this piece of hot steel, make the turn and go back over the top of the hot steel and then go through the pancake coils. Many of the better wood stove designs have this kind of a design. It can be made more complex if you want by welding ribs to it for more heat exchange surface and to limit warping from the heat. If there is a problem with smoke going up the chimney after everything is warmed up, then you will want to put some secondary combustion air into the top area to finish burning the smoke. This works better if there is some method for pre-heating the secondary combustion air, with pipes or tubes or something in the fire. Any time you want to make steam just lower the rate of water pumping and it will make steam. Controlling the steam production is a whole another story and there are several ways to do it, none real easy. Good luck. Tom Kimmel | |||

* | |||

=Peer Review= | =Peer Review= | ||

*'''[[Zach Dwiel]]''' - Are those btu calculations per hour or per day? | *'''[[Zach Dwiel]]''' - Are those btu calculations per hour or per day? | ||

Revision as of 23:16, 26 October 2012

Introduction

This is a hydronic space heating stove where the heat exchanger is located in an openable fire chamber. Identical design may be used to run the Hadden Modern Steam Engine if at full blast. The intent is space heating of 2000 square feet, including hydronic radiators for remote rooms.

Heat Exchanger

- 160 feet

- Pancake coil configuration, 4" inner hole, 22" OD of pancake

- 1/2" schedule 40 black pipe

- $2/foot materials cost for coil

- See YouTube for Coil Fabrication

Stove

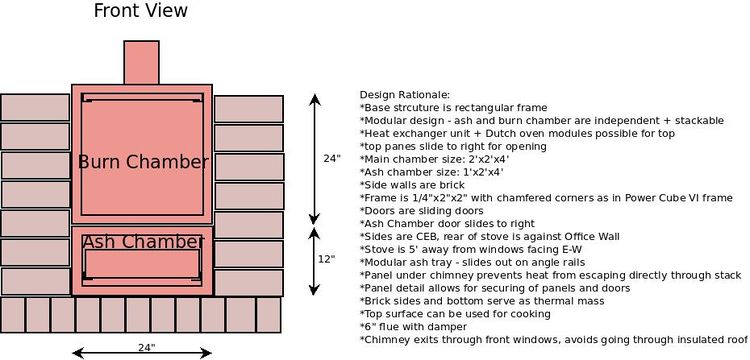

Concept

Design For Fabrication

Summary:

- Stackable chambers

- Modular faces for configuring as metal or masonry stove

- Modular throughout for addition of functional chambers such as baking oven or heat exchanger

- Faces open by sliding, lock with clamping bolt

Modular Stove Fabrication Procedure

Heat Calculations

See https://docs.google.com/spreadsheet/ccc?key=0Ani3apcWYfzDdGhGblBJczdZTVBHVi1GdzduVkotQlE#gid=1

If square footage of hablab is 3000 and average height is 8 feet, the cubic volume is 24,000 cubic feet.

BTU Requirement Formula = cubic footage * .133 * fahrenheit degree change = ~200,000 btu

Expert Review

- October 26, 2012 - from Tom Kimmel, President, SACA - This is basically a good design. What you want is a large volume so you can load it with large chunks or logs of wood. The Startup Flue Pipe is a very good design detail. It can be used for startup and then again as a by-pass if the heat exchangers are getting too hot for any reason. There is one addition I would make and that is to put a thick piece of steel in there about 2 or 3 inches below the top of the stove. It will be a few inches shorter than the stove with the space being near the front door. What you want to do is to get a complete burn of the smoke by making it go up from the fire, run along this piece of hot steel, make the turn and go back over the top of the hot steel and then go through the pancake coils. Many of the better wood stove designs have this kind of a design. It can be made more complex if you want by welding ribs to it for more heat exchange surface and to limit warping from the heat. If there is a problem with smoke going up the chimney after everything is warmed up, then you will want to put some secondary combustion air into the top area to finish burning the smoke. This works better if there is some method for pre-heating the secondary combustion air, with pipes or tubes or something in the fire. Any time you want to make steam just lower the rate of water pumping and it will make steam. Controlling the steam production is a whole another story and there are several ways to do it, none real easy. Good luck. Tom Kimmel

Peer Review

- Zach Dwiel - Are those btu calculations per hour or per day?

- Ben Hansen - Put a Catalytic Converter under the coil, that will keep it from being a drippy tar magnet, and you can focus the heat on to the coil pack. A big burn chamber, line it with firebrick, secondary coil and heat exchange area works well. Model to look at is a simple barrel stove double barrel kit.

- Aaron Makaruk -

- The surface of the barrel can be used for cooking.

- The water pipes are easier to channel throughout the HabLab than a Rocket Mass Stove exhaust pipe.

- Experiment option: pancake coil on top of the barrel.

- Experiment option: vertical coil along the vertical exhaust shaft of the rocket mass stove.

- Ben Hansen - catalytic converters in Mother Earth News - also source - Bought stuff from these guys. The "men" link is old, and reference only. Lots of good stuff out there now.

- Darren Hill - I have built a top lit side draft gasifying stove based upon GTZ7 with great help from the designer via the stoves list it is small and appears to require fuel to be processed accordingly (read small, still under testing). I think a larger version could work well with bigger logs. A restricted flue outlet, with alternative path enables heat exchanger to be brought into play aromatically as the burn establishes and volume of output gases exceeds that which the restricted outlet can flow. A suitably sized flue will provide the required draft to provide good combustion. I think I'm right in saying that the more complete combustion achieved in a gasifier stove should drastically reduce any tar deposits on the heat exchanger. --DOHill 14:24, 23 August 2012 (CEST)

- Parker Bonnell - Link to FAQ about catalytic stoves. Guide to the stoves. List of manufacturers and options.