Lucas's Log: Difference between revisions

Lucas Warner (talk | contribs) |

Lucas Warner (talk | contribs) |

||

| Line 53: | Line 53: | ||

New things I've learned: | New things I've learned: | ||

*The exit ports coming off of the valve control panel should face their destination. That way, straight fittings can be used, as opposed to elbows which were used exclusively on the first LifeTrac and used less on the most recent version. A combination of smooth, gently-curved pathways and '''short''' pathways help reduce drag. | *The exit ports coming off of the valve control panel should face their destination. That way, straight fittings can be used, as opposed to elbows which were used exclusively on the first LifeTrac and used less on the most recent version. A combination of smooth, gently-curved pathways and '''short''' pathways help reduce drag. Also, apparently, cavitation is an associated problem with turbulence in hydraulic systems. I thought it was only a problem with water. | ||

*straight fittings reduce the number of potential leak points as compared with using elbows. Low maintenance and durability are priorities of OSE machines. | *straight fittings reduce the number of potential leak points as compared with using elbows. Low maintenance and durability are priorities of OSE machines. | ||

Revision as of 18:52, 6 June 2013

Lucas's Log, Summer Internship 2013

June 3

June 4

Work on the MicroTrac:

I'm currently working on this (8:00pm June 4) I will soon have a written description of the day's proceedings and thought processes. For now, here is my work on the MicroTrac:

File:MicroTrac seat and controls (prototype).skp

June 5

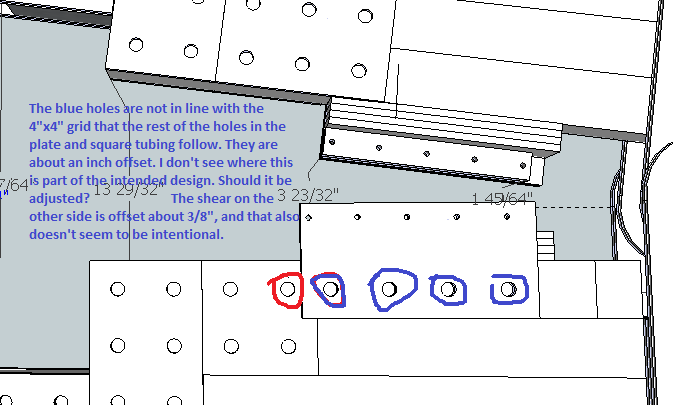

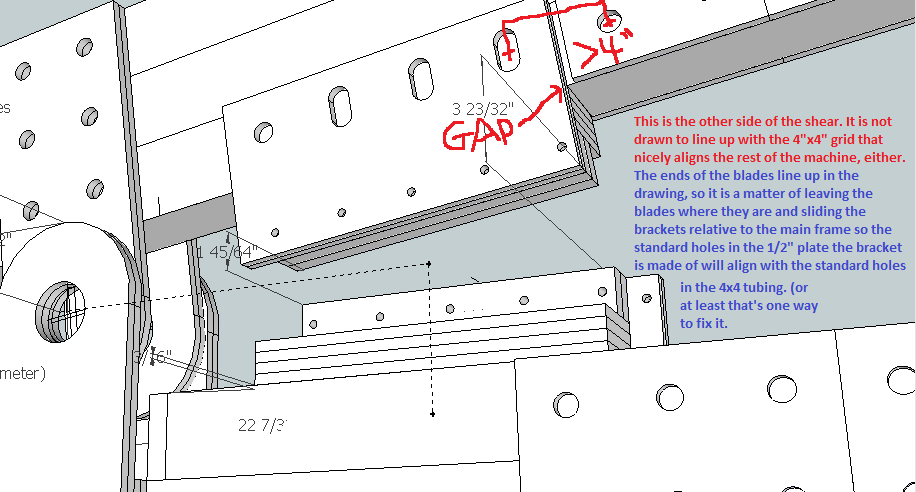

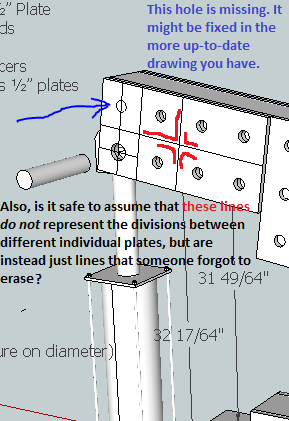

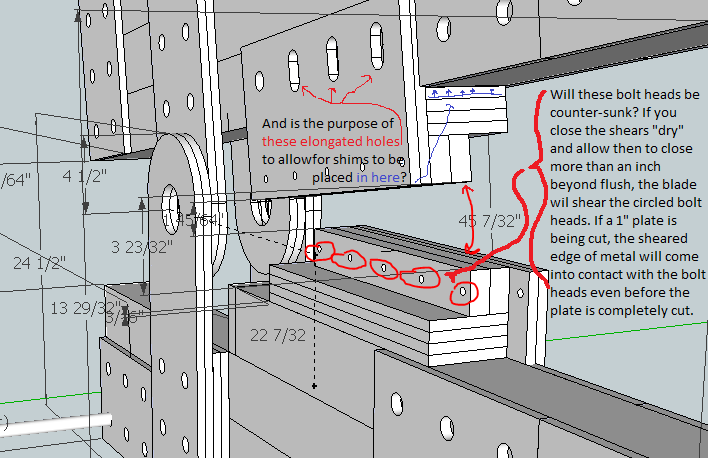

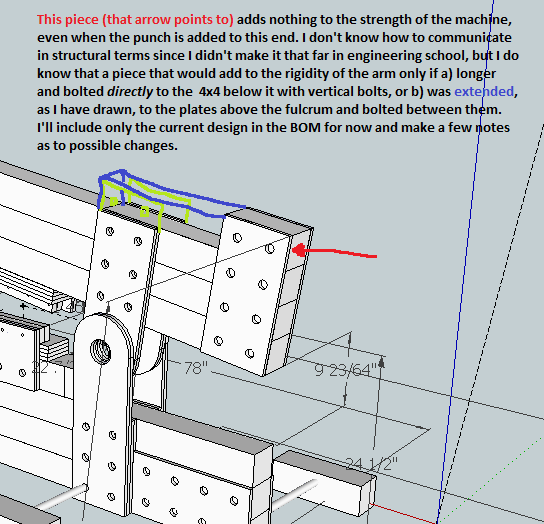

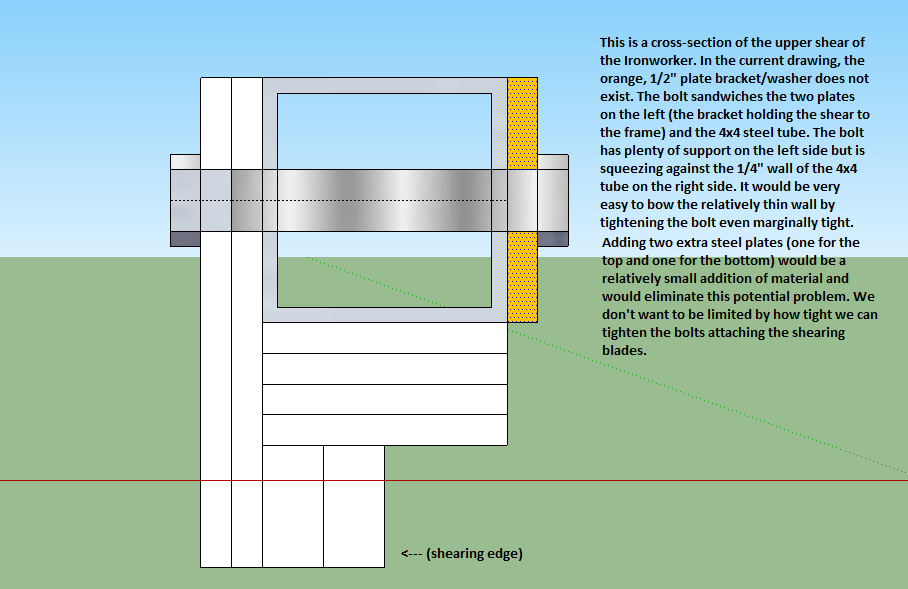

Proof-Reading the IronWorker Drawing

Here is the IronWorker SketchUp file. Design concerns detailed in the images below are not reflected in the updated SketchUp file. This file does have the updated/corrected BOM.

June 6

Hydraulics for the MicroTrac

I am tasked with reading up on basic hydraulic systems and beginning to design the hydraulic pathways that power the components of the MicroTrac (the wheels and the quick attach for the implements). Some of the basics I already know: how hydraulic pistons, pumps, and motors work in conjunction with the fluid reservoir and return tank. I also know that the fluid is being pumped at all times in a short, circular pathway and that valves are used to divert portions of that flow to the various hydraulic components on the machine. I also know that the system will work most efficiently when the hydraulic tubes are directed along pathways that allow for the gentlest curves and bends as practical. That's because the pattern of flow of a fluid within a tube or hose is laminar (friction between the fluid and the inner surface of the tube causes that fluid to move slower and the fluid in the center of the tube moves more quickly). That friction cannot be helped except by increasing the diameter of the hoses or changing the texture of the interior surface of the hoses, both of which are probably optimized by the hose manufacturers. What we must consider in the design is the routing of the hoses for best performance. When there are obstructions in the hose or sharp bends, turbulence increases friction dramatically and can sometimes bring the fluid nearly to a stop. When designing a micro-hydro power system at home, I had to learn about all these things about fluid flow. More updates and drawings to follow...

New things I've learned:

- The exit ports coming off of the valve control panel should face their destination. That way, straight fittings can be used, as opposed to elbows which were used exclusively on the first LifeTrac and used less on the most recent version. A combination of smooth, gently-curved pathways and short pathways help reduce drag. Also, apparently, cavitation is an associated problem with turbulence in hydraulic systems. I thought it was only a problem with water.

- straight fittings reduce the number of potential leak points as compared with using elbows. Low maintenance and durability are priorities of OSE machines.