Core Team: Difference between revisions

| Line 33: | Line 33: | ||

The OSE product development effort is unique in that it does not stop with the development of a good product. We continue for the sake of replicability, such that the products developed can enjoy a wider audience. We continue our product development process to the design and building of a production facility, such that people who support our effort can later have access to products at reasonable cost. Not only this, but also, one of our inherent goals is optimization of the product and its production process. To introduce the possibility of even wider markets, we are also designing a training and apprenticeship program to our product development. We aim to train other entrepreneurs in the production of products, and as such, our work constitutes a business incubator. Because we aim to train others, we are introducing the possibility of production levels similar to mass production methods, except with the participation of a large number of producers. Because we are focusing on optimization for cost reduction, we believe that we can compete with the mainstream market, without any ecological or geopolitical compromises. | The OSE product development effort is unique in that it does not stop with the development of a good product. We continue for the sake of replicability, such that the products developed can enjoy a wider audience. We continue our product development process to the design and building of a production facility, such that people who support our effort can later have access to products at reasonable cost. Not only this, but also, one of our inherent goals is optimization of the product and its production process. To introduce the possibility of even wider markets, we are also designing a training and apprenticeship program to our product development. We aim to train other entrepreneurs in the production of products, and as such, our work constitutes a business incubator. Because we aim to train others, we are introducing the possibility of production levels similar to mass production methods, except with the participation of a large number of producers. Because we are focusing on optimization for cost reduction, we believe that we can compete with the mainstream market, without any ecological or geopolitical compromises. | ||

==Price Structure== | ==Price Structure of Developed Products== | ||

At the same time, we pay attention to the bottom line. Because the product development process and fabrication facility is microfunded collaboratively, our capitalization costs are zero. Therefore, we can focus on maximum service to the consumer. With this in mind, our products will be sold at cost: at the cost of materials plus labor. How can we survive doing this? We are still capturing the high value of skilled labor, at $50-100 per hour. This is a reasonable figure. To begin with, general labor is $50 at a typical machine shop or garage. Since we are aiming for advanced, digital fabrication techniques, our productivity is extremely high, and the $50-100 is worth it. To give an example, our [[CEB Press]] costs $1350 in materials and we predict 20 hours of labor for optimized fabrication. If we charged $50-100/hour in labor, that would make the product price $2350-$3350 - which is about a factor of 8-10 lower than the competition (see discussion at [[CEB Press]]. This shows that there is plenty of room for the producer to capture value, while the customer comes out ahead as well. This scenario is possible once optimal fabrication procedures are developed, a goal which we take as a premise for our work. | At the same time, we pay attention to the bottom line. Because the product development process and fabrication facility is microfunded collaboratively, our capitalization costs are zero. Therefore, we can focus on maximum service to the consumer. With this in mind, our products will be sold at cost: at the cost of materials plus labor. How can we survive doing this? We are still capturing the high value of skilled labor, at $50-100 per hour. This is a reasonable figure. To begin with, general labor is $50 at a typical machine shop or garage. Since we are aiming for advanced, digital fabrication techniques, our productivity is extremely high, and the $50-100 is worth it. To give an example, our [[CEB Press]] costs $1350 in materials and we predict 20 hours of labor for optimized fabrication. If we charged $50-100/hour in labor, that would make the product price $2350-$3350 - which is about a factor of 8-10 lower than the competition (see discussion at [[CEB Press]]. This shows that there is plenty of room for the producer to capture value, while the customer comes out ahead as well. This scenario is possible once optimal fabrication procedures are developed, a goal which we take as a premise for our work. | ||

Revision as of 03:55, 29 January 2008

Core Team Duties

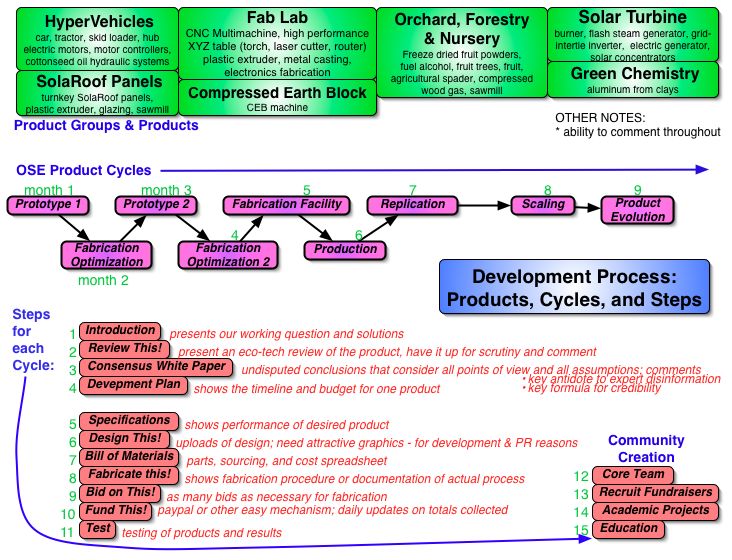

The Core Team is the organizational heart of OSE's product development. The Core Team leads the development of each of the 7 product areas shown in the Overview. The Core Team is responsible for producing the due diligence and engineering- specifications, designs, fabrication procedure, bill of materials, peer reviews - to make prospective supporters sufficiently confident to support the products in development.

Core team members should have technical expertise, but it is not necessary. We are interested more in people who can solve problems. The nature of our appropriate technology (AT) development is such that the material, by nature of AT - is simple, user friendly, and intuitive. It may be said that the utter simplicity is the hallmark of a great product. Therefore, only the most fundamental knowledge, at the level of high school physics and mathematics, is necessary for the core team. Part of being on the Core Team means that the member learns the additional knowledge necessary for high-level development.

Specific Duties

The specific path of our product development is cycles and steps within these cycles. The typical cycles and steps are shown in this diagram:

The cycles follow a standard type of product development: prototypes, optimization, and fabrication. The additional twist on such standard model are that we will be replicating our production capacity by serving as a business incubator with apprenticeship training.

The particular steps for each cycle are described further at Main Page#OSE Product Cycle. Note that we can propose only a general outline of the steps, as development processes will rarely fall into neat steps. This is where the problem-solving ability of the Core Team must enter to provide appropriate guidance to the project.

Core Team Number

* Core team should be small, but funders should be many

* Funding cycles should be short - one month - to make progress visible and help risk sharing

* Simplest way to phrase the neosubsistence economic model is "Buying Club for Open Source Product Development"

o The Buying Club metaphor goes only so far as distributing cost among buyers to purchase better, lower cost products

*

We need to focus on recruiting core teams to accelerate progress

o This is time-taking work, but there is no easy way to produce mass participation

* We should use a Wikipedia-like model - gather a core team of distillers who add value to information from a large number of sources

o The main difference between our model and Wikipedia is that Wikipedia gets random, voluntary contributions (of content). We will solicit those contributions (of information), since our contributions are of a far more directed, though not necessarily more technical nature (as Wikipedia has some very technical content).

o It may be an interesting avenue to solicit help from the Wikipedia team to get our core teams organized. They may point us to people who may be interested in being on our core teams

o We need to define the roles of the core team more clearly. Recruiting the core team should be an ongoing, piecemeal effort. There is no magic bullet.

Scope of Product Development

The OSE product development effort is unique in that it does not stop with the development of a good product. We continue for the sake of replicability, such that the products developed can enjoy a wider audience. We continue our product development process to the design and building of a production facility, such that people who support our effort can later have access to products at reasonable cost. Not only this, but also, one of our inherent goals is optimization of the product and its production process. To introduce the possibility of even wider markets, we are also designing a training and apprenticeship program to our product development. We aim to train other entrepreneurs in the production of products, and as such, our work constitutes a business incubator. Because we aim to train others, we are introducing the possibility of production levels similar to mass production methods, except with the participation of a large number of producers. Because we are focusing on optimization for cost reduction, we believe that we can compete with the mainstream market, without any ecological or geopolitical compromises.

Price Structure of Developed Products

At the same time, we pay attention to the bottom line. Because the product development process and fabrication facility is microfunded collaboratively, our capitalization costs are zero. Therefore, we can focus on maximum service to the consumer. With this in mind, our products will be sold at cost: at the cost of materials plus labor. How can we survive doing this? We are still capturing the high value of skilled labor, at $50-100 per hour. This is a reasonable figure. To begin with, general labor is $50 at a typical machine shop or garage. Since we are aiming for advanced, digital fabrication techniques, our productivity is extremely high, and the $50-100 is worth it. To give an example, our CEB Press costs $1350 in materials and we predict 20 hours of labor for optimized fabrication. If we charged $50-100/hour in labor, that would make the product price $2350-$3350 - which is about a factor of 8-10 lower than the competition (see discussion at CEB Press. This shows that there is plenty of room for the producer to capture value, while the customer comes out ahead as well. This scenario is possible once optimal fabrication procedures are developed, a goal which we take as a premise for our work.

Additional notes

- Sam Rose is working on http://socialsynergyweb.org/opensourceecology/node/add/wikipage as a space for coordinating core teams, Core Team members should visit this site regularly

- In order to appreciate the nature of the economic model that we are testing, Core Team members should start with http://p2pfoundation.net/Neocommercialization , and this definition should evolve to help communicate the model