Open Source Induction Furnace Project: Difference between revisions

mNo edit summary |

(→Notes: Added section: Melt Calculations) |

||

| Line 46: | Line 46: | ||

*50 kw STC 3 phase- $1300 - [http://cgi.ebay.com/50KW-STC-3-Phase-12-Wire-generator-alternator_W0QQitemZ160357088416QQcmdZViewItemQQptZBI_Generators?hash=item255606fca0] | *50 kw STC 3 phase- $1300 - [http://cgi.ebay.com/50KW-STC-3-Phase-12-Wire-generator-alternator_W0QQitemZ160357088416QQcmdZViewItemQQptZBI_Generators?hash=item255606fca0] | ||

**LifeTrac 55 hp can produce 38 kW with this head | **LifeTrac 55 hp can produce 38 kW with this head | ||

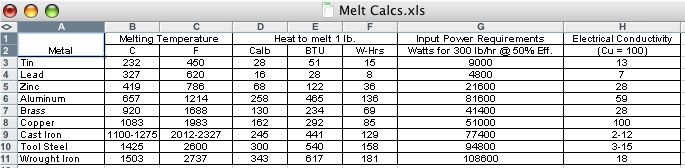

===Melt Calculations=== | |||

[[Image:inductioncalc.jpg]] | |||

==See Also== | ==See Also== | ||

Revision as of 18:25, 24 January 2010

Introduction

This project involves the design of:

- a high frequency, high-power induction furnace circuit (between 20 and 50 kW), and

- the melting chamber proper.

Well, we could buy a turnkey system perhaps for $5k total used, and run it from the LifeTrac generator. The only disadvantage to this route is that if it breaks we’re dead-in-the-water – either with the impossibility of fixing closed-source technology, or a high repair bill. A single component which blows and is inaccessible for fixing could in principle turn a working power supply into worthless junk. Thus, it is worthwhile to tame this technology by open-sourcing the design.

Goals

The furnace should have the following characteristics:

- Induction furnace or any other technology that can do this within a budget of 20 kW of electric input, with minimal pollution

- Suitable for melting all metals and alloying

- 300 lb per hour steel melting furnace for casting

- 240 v ac, 20 kW power source available

Details

The complete design should include all of the following:

Induction Furnace Circuit

- Scalable from 20 up to 50 kW in units of 1 or 5 kW

- Allows for power and frequency selection

- Power source may be either 1 or 3 phase electrical power

Heat Dissipation System

Specifications of a cooling or heat dissipation system.

Coil

- Modular, adaptable design specifications for primary coil windings

Melt Chamber

- Geometical design of melt chamber and basic power transfer calculations

- Should include provisions for loading and pouring.

Other Considerations

- Complete bill of materials

- Fabrication files for circuit and other components

- Sourcing information for components

- System design and process flow drawings

Notes

Power Supply

- 50 kW for $1600 - [1]

- 20 kw STC 3 phase 120 - 480V, also 1 phase - generator - $692 -[2]

- 50 kw STC 3 phase- $1300 - [3]

- LifeTrac 55 hp can produce 38 kW with this head

Melt Calculations

See Also

- Original blog post: http://openfarmtech.org/weblog/?p=1373

- Furnace selection: http://www.articlesfactory.com/articles/hobbies/induction-furnace-and-cupola-furnace-information.html

DIY Furnaces

- http://www.richieburnett.co.uk/indheat.html

- http://www.hvguy.4hv.org/ih/

- http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat1.html

- 1 kW Induction Furnace Kit: http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat8.html

- http://www.dansworkshop.com/electricity-and-electronics/induction-heating.htm

Commercial

- Commercial induction furnace power supplies from Superior Induction - [4]

- EPRI works with induction - The EPRI Center for Materials Production at Carnegie Mellon, Pittsburgh, PA, 412-268-3243

If you think there are missing or incorrect details here, please help correct that.