Anthony douglas log: Difference between revisions

No edit summary |

No edit summary |

||

| Line 38: | Line 38: | ||

=March 14= | =March 14= | ||

Hopefully Michael and I will extract the DXF files from the completed sketchup model of the mixer/pulverizer, and dimension them. Dimensioning is something I can definitely do, so if we do not finish, I can do that in the days ahead. Then we will have a complete set of drawings to fabricate from. | Hopefully Michael and I will extract the DXF files from the completed sketchup model of the mixer/pulverizer, and dimension them. Dimensioning is something I can definitely do, so if we do not finish, I can do that in the days ahead. Then we will have a complete set of drawings to fabricate from. | ||

The morning and early afternoon was spent on domestic labor, and till 6 pm whitewashing and painting. Then we reviewed the design of the soil pulverizer, decided on a few final modifications, after which we will be ready to export things to dxf orthographic views from sketchup, and from there dimension the parts. Michael has homework and Andrew a splinter, so to move ahead I will try to export the parts that do not require modification. In the future Inventor and probably other CAD rather than graphics software can automate this entire process easily with a few clicks. | |||

Revision as of 02:20, 15 March 2014

Sun Mar 9, 2014

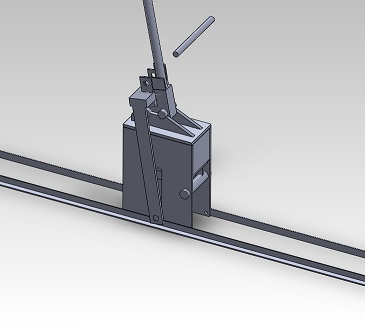

- Pulverizer and mixer design session in the morning.

- Afternoon work included cutting plywood sheets w/ table saw with Coltan, painting the boards, then helped mud up the cracks in the micro house, moving some scrap metal and helping with the dishes. One interesting thing was the difficulty of stuffing the mud into cracks and against the wall due to it's failure to stick well, then the discovery later in the day that mud near the fire was far stickier and would have been a great labor saver. It shows the importance of a brief practical exploration period. Another thing that made a huge difference, which I expected probably existed, was the technique Marcin showed us to get the mud in the walls; take a trowel with mud piled on it and force it against the wall with another, with the first trowel held underneath.

Monday, March 10

We made good progress in the design of the pulverizer/mixer, essentially settling on the high level design and finishing the 3d sketchup model. Going out to see the stuff was a great aid, and seemed to inspire and catalyze thinking in the group. In the afternoon I and some others focused on finishing the microhouse interior walls, with the chicken wire and plaster/pearlite mix. I returned in the evening and did another batch, timing myself it took 28 minutes to mix and apply a batch of the plaster mixture, we will certainly be done the lower layer tomorrow, then there is a final finish layer. I am going to bed now immediately after this, entering the log entry and eating, I think, as I have been getting increasingly sleep deprived over the past week. Yesterday and today I tried to remove the ton of malware on this computer with avg free, malwarebytes and the online trendmicro software, which have helped, but there is still something interfering with the browser severely.

Tuesday, March 11

Morning design. Eric and I measure the tines modules and the more critical rotor dimensions, so he can model it in scad. I document the process itself, in Process used march11 2013 to model an object for concept sketch in scad [1]. My abilities in Inventor are too limited for now to do this in a reasonable time frame, I think, but I will download a copy now so I can try to draw things tonight. I decided to focus on other things until now, since there are others in the group who can draw well, to be the most effective team player I can. I still need to get the pictures I have taken up non trovebox, I was hoping to do so this morning, but the internet connection was down.

This afternoon I spent mostly on preparing the exterior wall of the hab lab, then limewashing it, and painting the interior with the yellow.

March 12

Got an error message when trying to install the 32 bit version of Inventor, which took since yesterday to download. The 32 bit version won't run on windows 8, so I need to download the 64 bit, back to square one. The importance of having your means of production with you or handy. Andrew had a similar problem, not having his SolidWorks with him. Probably because he never used his laptop to with it.

The morning was spent progressing on the fabrication plan for the soil mixer/pulverizer. This is particularly helpful as it helps iron out some off the design details, such as the manner in which the tine modules interface to the rotor shaft etc. They can be found linked to on the wiki through Dozuki under "build instructions" for the overall and also for the rotor module. I would greatly prefer to add some images, but the feature to add images to the wiki of the existing pulverizer to make things more clear to the reader, and also for Dozuki was not functional at the time, though it seems to be working now for the wiki, so I may revisit this later.

The afternoon was spent moving the swimming pool (parts), limewashing, cleaning at the microhouse, moving lumber and other small tasks that add up.

Very interesting discussion around the fire last night, as you might hope when people who are interested in a project like this come together.

March 13

Last day for most of us present here. Yesterday Andrew, Marcin, Catarina, Chris and I talked about continuing to volunteer here longer, because Andrew and I do not need to return to school as the others do. The plan is for the two of us to continue to accomplish things here on the same schedule, of CEB press in the morning, and infrastructure expansion in the afternoon, until the end of April, which is absolutely great. I was uncertain and didn't want to seem clingy, probably I went too far with that, but it is a fascinating, incredibly worthwhile and rich project here, and I was very much hoping I would find there were opportunities to continue helping to advance it, and all the learning by doing that goes along with that.

todo: Finish the pulverizer/mixer fabrication instructions for the overall and rotor, this includes adding some pics and the note regarding the relative position on the tines on the tine modules and a few other things (if the tine modules are identical, then the tines will all line up, which is not really what we want.) Doing this gives me a head start on doing the other parts, so I have that on my personal todo list and hope I won't have to jettison it, due to things on the list that I have committed explicitly to doing. Also included herein, is to get the drawings done thus far up on Dozuki. Inventor is done downloading, so I may be able to do something useful with that, too.

The afternoon will probably be lime washing and painting, and progress on the microhouse.

Indeed, it has been; helped clean the microhouse, limewash, move some things, gave the entryway trim a second coat, and began removing the stucco covered mdf/fiberboard material from the area next the the area with the polycarbonate, on the west side of the house above the backmost enclosed room, behind the bathroom showers. The board is slated to be removed and replaced with polycarbonate, but it is screwed in place, and the screw heads concealed with a thick layer of stucco. My appoach, disclosed in interest of those who might come after although I will probably finish it tomorrow, is to pry away a layer of the fiberboard, and therefore the stucco too, in the area a screw is probably located, rather than trying to remove the stucco. The use of the saw blade allows some searching while prying. Clean the screw head out with another screw, then, lift the board and look at the way it bends to determine the likely location of other screws.

March 14

Hopefully Michael and I will extract the DXF files from the completed sketchup model of the mixer/pulverizer, and dimension them. Dimensioning is something I can definitely do, so if we do not finish, I can do that in the days ahead. Then we will have a complete set of drawings to fabricate from.

The morning and early afternoon was spent on domestic labor, and till 6 pm whitewashing and painting. Then we reviewed the design of the soil pulverizer, decided on a few final modifications, after which we will be ready to export things to dxf orthographic views from sketchup, and from there dimension the parts. Michael has homework and Andrew a splinter, so to move ahead I will try to export the parts that do not require modification. In the future Inventor and probably other CAD rather than graphics software can automate this entire process easily with a few clicks.