RepRap Build: Difference between revisions

Jump to navigation

Jump to search

(→Parts) |

No edit summary |

||

| Line 3: | Line 3: | ||

=Parts= | =Parts= | ||

[[Image:rrparts.jpg|thumb|Part set from Chris Palmer of [http://hydraraptor.blogspot.com/2009/07/hydraraptors-second-child.html HydraRaptor]]] | [[Image:rrparts.jpg|thumb|Part set from Chris Palmer of [http://hydraraptor.blogspot.com/2009/07/hydraraptors-second-child.html HydraRaptor]]] | ||

[[Image:rrpartsendstops.jpg|thumb|Opto | [[Image:rrpartsendstops.jpg|thumb|Opto End Stops v2.1. There are three sets of these.]] | ||

[[Image:rrpartscontroller.jpg|thumb| | [[Image:rrpartscontroller.jpg|thumb|RepRap Mother Board v1.1.]] | ||

[[Image:rrpartsextrudercontroller.jpg|thumb|Extruder | [[Image:rrpartsextrudercontroller.jpg|thumb|Extruder Controller v.2.2]] | ||

*Frame corners and rods - using 5/16" rod. | *Frame corners and rods - using 5/16" rod. | ||

Revision as of 06:41, 19 July 2010

Parts

Part set from Chris Palmer of HydraRaptor

- Frame corners and rods - using 5/16" rod.

- Extruder controller - [1]

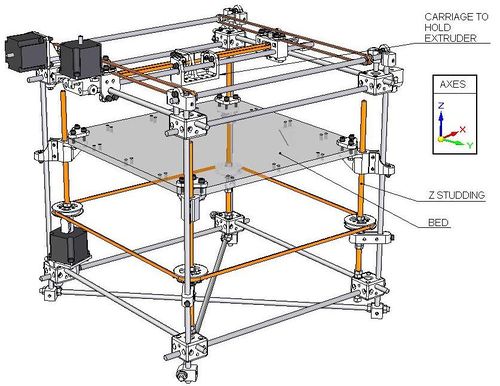

Assembly

From HydraRaptor

- $8 z axis from HydraRaptor

Notes

On Frame Rods

From Erik:

As long as they're about 8mm in diameter you're good. Everything is designed such that tight tolerances are not required. Part of assembling a machine is taking a series of measurement. You can get away with threaded rods for most of the structural parts, except for the elements that other parts should be able to slide over. Several parts of the frame double as a guide for an axis.

You can also use cheap rod for most of the frame, the sliding ones should be maximally stiff (hardened rod) and chrome coated is nice and shiny. I'm using only the cheap type of ground bars for my own second Darwin, currently. It works fine. You don't need a heavy CNC grade frame when doing additive manufacturing, it's just very inefficient.