Continuous Casting: Difference between revisions

Jump to navigation

Jump to search

| Line 8: | Line 8: | ||

=Twin Roll Casting= | =Twin Roll Casting= | ||

*Patent where sticking to rolls is eliminated by injecting oxygen for aluminum casting - [https://www.google.com/patents/US5588478] | *Patent where sticking to rolls is eliminated by injecting oxygen for aluminum casting - [https://www.google.com/patents/US5588478] | ||

:*The Iron and Steel Institute of Japan - [[File:twinrollcasting.pdf]] | |||

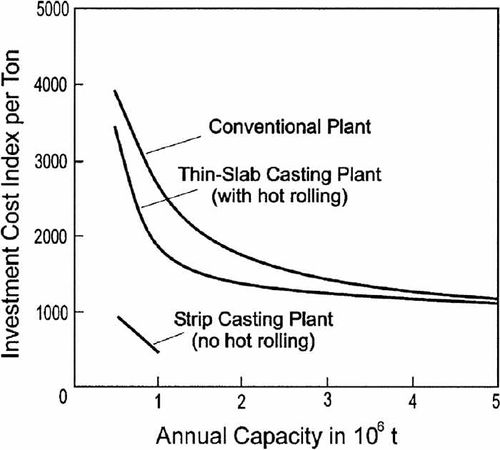

*Evolution of continuous casting proccesses diagram - | *Evolution of continuous casting proccesses diagram - | ||

[[File:castingevolution.jpg| | [[File:castingevolution.jpg|500px]] from [https://www.jstage.jst.go.jp/article/isijinternational/57/1/57_ISIJINT-2016-502/_html] | ||

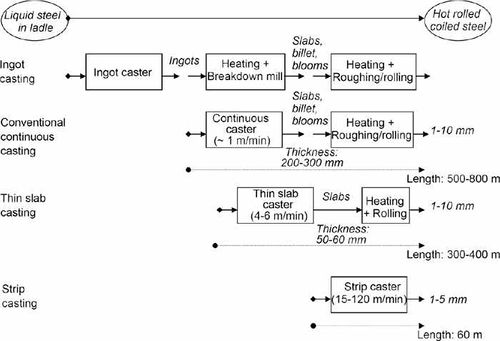

Also, see cost graph: | Also, see cost graph: | ||

[[File:castingcost.jpg| | [[File:castingcost.jpg|500px]] | ||

Revision as of 19:25, 27 December 2017

- Twin-Roll Casting from back in 1857 by Bessemer - [1]

- Direct Chill Casting vs. Twin Roll Casting animation - [2]

- Picture of twin roll casting process- [3]

- Nice lecture from IIT Roorkee on 4 types of continuous casting including double roll casting - [4]

- Video from 1969 - [5]

- Wayback content, with authors' names - [6]

Twin Roll Casting

- Patent where sticking to rolls is eliminated by injecting oxygen for aluminum casting - [7]

- The Iron and Steel Institute of Japan - File:Twinrollcasting.pdf

- Evolution of continuous casting proccesses diagram -

from [8]

from [8]

Also, see cost graph: