Boundary Layer Turbine: Difference between revisions

| Line 36: | Line 36: | ||

[[Image:turbine_BOM.jpg]] | [[Image:turbine_BOM.jpg]] | ||

=Development Log= | |||

See the [[Turbine Development Log]]. | See the [[Turbine Development Log]]. | ||

=Turbine Fabrication: General= | |||

See [[Turbine Fabrication]] | See [[Turbine Fabrication]] | ||

=Turbine Fabrication: Materials and Tolerances= | |||

We begin with a shaft. It should be some form of hardened steel, either machinable hardened steel or A36 that is subsequently hardened. The case can be any machinable steel. | |||

Tolerances: | |||

Shaft: 1.500" +0.0000/-0.0005 | |||

Disks: laser cut - see [[http://openfarmtech.org/index.php?title=Turbine_Fabrication#Disks here.]] | |||

=Prior Work= | =Prior Work= | ||

Revision as of 00:53, 26 March 2008

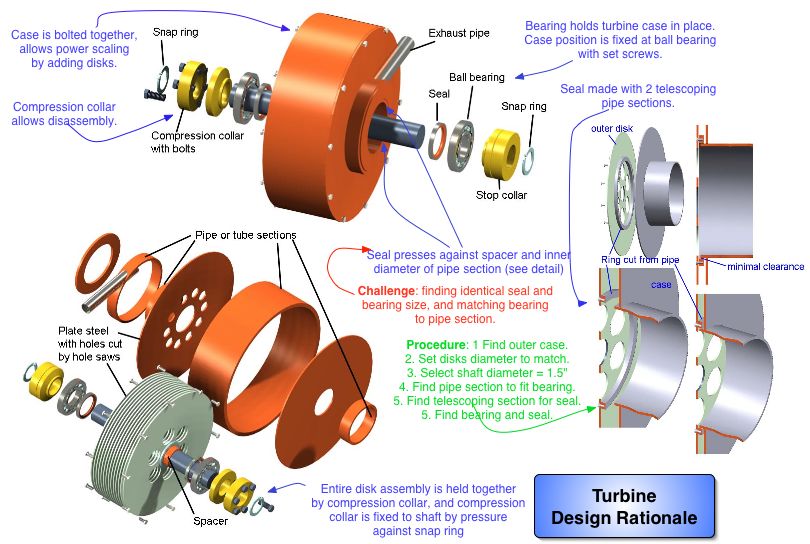

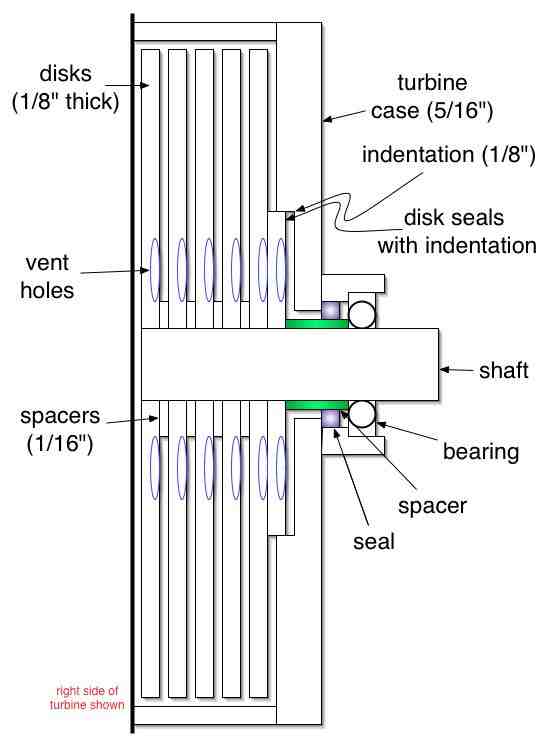

Design Rationale

Drawings by Dan Granett, Granett Engineering:

This is an external combustion engine with proven efficiencies of 25% for un-optimized models with steam (Rice, Warren, Transactions of the ASME, Journal of Engineering and Power, January 1965, pp. 28-36). A working fluid spins this turbine by means of surface friction. When the disk spacing is small (on the scale of a millimeter), energy transfer from the working fluid to the disks can be efficient. Design rationale:

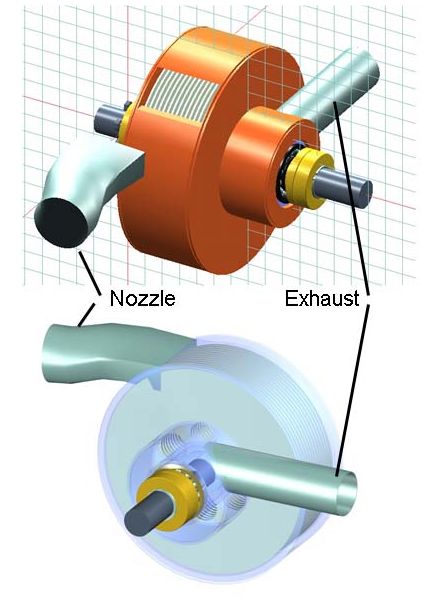

Working fluid (such as steam) enters tangentially to the disks through a nozzle:

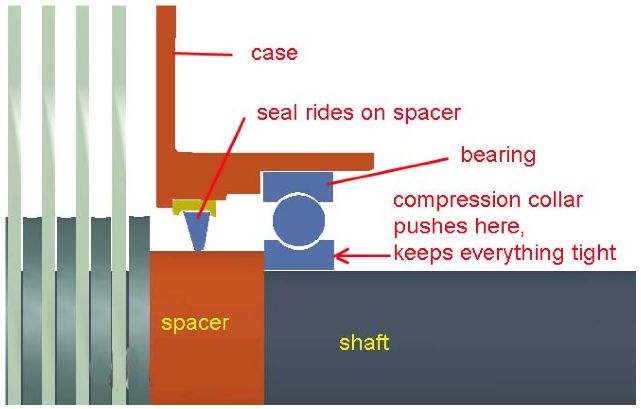

Bearings must be protected from the working fluid with a shaft seal seal:

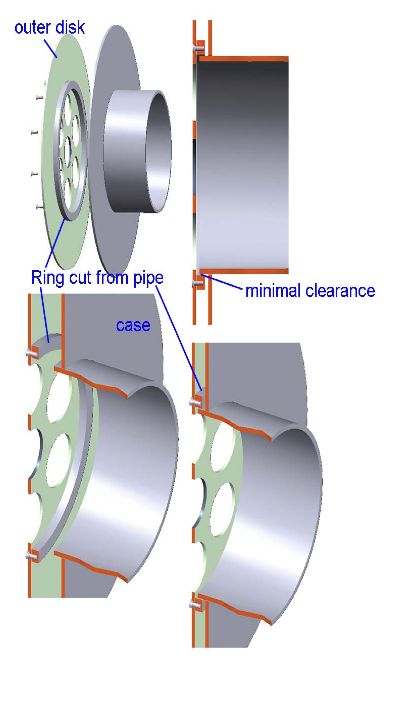

Working fluid must be prevented from escaping past the outer disks so that it can transfer its energy effectively to all the disks. To do this, we put in a ring seal:

Simplified Seal Design

The main seal (not the ballbearing seal) may be simplified as follows:

Bottom Line: Simplicity

The bounary layer turbine is the simplest design of a turbine possible, and it has a respectable efficiency of 25% without optimization. For the significantly lower simplicity and cost, it's a competitor with bladed steam turbines. Compare this to the steam turbines of modern power plants, and you can appreciate the difference:

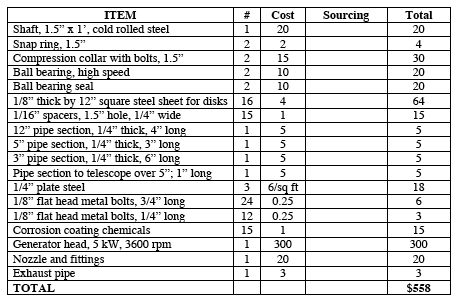

Bill of Materials: Boundary Layer Turbine

The materials cost for the boundary layer turbine, including generator head, is:

Development Log

See the Turbine Development Log.

Turbine Fabrication: General

Turbine Fabrication: Materials and Tolerances

We begin with a shaft. It should be some form of hardened steel, either machinable hardened steel or A36 that is subsequently hardened. The case can be any machinable steel.

Tolerances:

Shaft: 1.500" +0.0000/-0.0005 Disks: laser cut - see [here.]

Prior Work

A working model of this turbine has been built several years ago. This model was more involved with respect to the fabrication procedure. The work above is a simplification in design. See [here].

License

This design is open source. It is placed explicitly in the public domain for the benefit of all humankind. Our license is copyleft. We encourage any user of this information to place any further developments in the public domain for others to build on.