Precious Plastic Shredder: Difference between revisions

| Line 1: | Line 1: | ||

=Torque and RPM= | =Torque and RPM= | ||

*The torque of the Precious Plastic shredder is recommended at 70 rpm with a 1/4 hp or higher motor. Using the Motor Torque Calculator, that comes out to 2800 N cm. The stepper motor above meets this specification. | *The torque of the Precious Plastic shredder is recommended at 70 rpm with a 1/4 hp or higher motor. Using the Motor Torque Calculator, that comes out to 2800 N cm. The stepper motor above meets this specification. | ||

* | *50-100Nm was an educated guess, but I’ve since got my shredder working and taken some measurements. To shred bottle tops takes a maximum 20Nm, to shred the thickest plastic I could find (front panel of a domestic appliance) took 60Nm. Note that my machine is half the size of DH’s, so for that I would expect the figures to be roughly double, perhaps slightly less as the teeth are more pointed and will probably pierce with less force." - from [https://davehakkens.nl/community/forums/topic/almost-definitive-guide-on-motors-wip/#post-70822] | ||

50-100Nm was an educated guess, but I’ve since got my shredder working and taken some measurements. To shred bottle tops takes a maximum 20Nm, to shred the thickest plastic I could find (front panel of a domestic appliance) took 60Nm. Note that my machine is half the size of DH’s, so for that I would expect the figures to be roughly double, perhaps slightly less as the teeth are more pointed and will probably pierce with less force." - from [https://davehakkens.nl/community/forums/topic/almost-definitive-guide-on-motors-wip/#post-70822] | |||

=Source= | =Source= | ||

Revision as of 00:21, 19 September 2018

Torque and RPM

- The torque of the Precious Plastic shredder is recommended at 70 rpm with a 1/4 hp or higher motor. Using the Motor Torque Calculator, that comes out to 2800 N cm. The stepper motor above meets this specification.

- 50-100Nm was an educated guess, but I’ve since got my shredder working and taken some measurements. To shred bottle tops takes a maximum 20Nm, to shred the thickest plastic I could find (front panel of a domestic appliance) took 60Nm. Note that my machine is half the size of DH’s, so for that I would expect the figures to be roughly double, perhaps slightly less as the teeth are more pointed and will probably pierce with less force." - from [1]

Source

- https://preciousplastic.com/en/videos/build/shredder.html

- Imperial version of knives for shredder - for 1" hex shaft - https://davehakkens.nl/community/forums/topic/shredder-modifications/

- Imperial steel overall - https://davehakkens.nl/community/forums/topic/shredder-converted-to-imperial-system-inches/

Screen

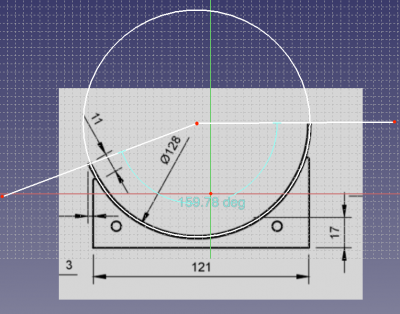

Dimensions of screen are found in blueprints.

Shredder screen width is verified here based on angle - uses PDF of fabrication drawings imported into FreeCAD for tracing over

Source: File:Screen.fcstd

- 160 / 360 * 2 pi * r = 178 mm = 7 inches

- r=64

- Actual screen - 149x180x1.5 mm = 5.9 x 7.1 x 0.06 in

- 1.5 mm is 16 ga = 0.06 inch. Use 1/4" holes.

Sourcing

- McMaster Carr - [2]

OSE Mod

See working team meeting -

The Precious Plastic shredder is great. By using 1" hex shaft and 1" hex bearings, we avoid machining the shaft ends. Using 3D printing, a hex coupler is obtained readily, printed at 100% infill.

The advantage of using hex for the coupler is not needing keyways or set screws, though these can be used for additional holding force.

If PLA is 7250 PSI, that is 1/5 of mild steel. Thus, a plastic coupler can readily do 1000s of lbs of shaft holding force. FOr example, on a 1" shaft, one can likely attain 15000 in lb of hold using a coupler with 3/4" walls. It is useful to use a coupler with a metal sleeve, using 2" schedule 40 pipe, with the coupler press fit inside of the sleeve for a metal-plastic composite coupler. The plastic walls in this case would be around .5".

Builds

Precious Plastic Imperial CAM Files - Imperial Version with 1" Hex Shaft

BOM

- 1" hex shaft - [3]

- 1" hex bearings only - [4]. More specs at 1" Hex Bearing.

- 1" hex bearing block $20 - [5]

- 1" hex bearing block $11 - [6] - Your order number is 1021 - If you have any questions about your purchase, email us at johnj@mid-westmade.com or call us at 641-572-0194.

- Motor + Geardown - 5/8" output shaft on geardown handles 1/2 hp

- 5/8" coupler - [7]

CAD/CAM

- Overall File in FreeCAD - export of Precious Plastic - File:Pp shredder.zip

- Bearing holder for 2.44" OD hex bearing (see BOM) - File:Hexholder.fcstd. STL - File:Hexholder.stl

- Bearing holder with motor mount - offset from body of the shredder as a 1-piece 3D printed Motor Mount with integrated bearing - File:Hexholdermotor.fcstd. STL - File:Hexholdermotor.stl

- M from 1" hex shaft to 1/2" round with keyway, - File:1hextohalf.fcstd. File:1Hextohalf.stl