Hillbilly Heater: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 1: | Line 1: | ||

[[Image:comeback.png|thumb|Install of hillbilly heater in 2016 - Seed Eco-Home. <html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10214807921928782&width=500" width="500" height="342" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> ]] | |||

=Formula for Heat Transfer= | =Formula for Heat Transfer= | ||

[[Image:thermalcalc.jpg]] | [[Image:thermalcalc.jpg]] | ||

Revision as of 09:04, 27 October 2018

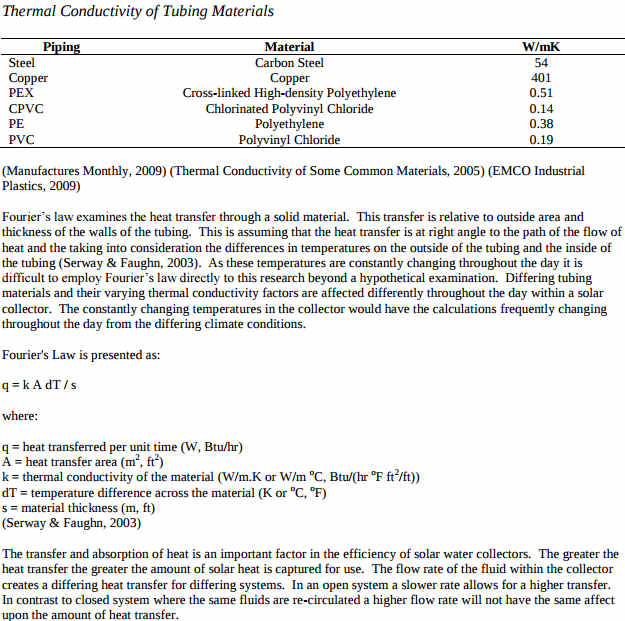

Formula for Heat Transfer

(source: [1])

Industry Standards

- Hillbilly heater - 30 sf or 2 sq meters per 500' roll of 1/2" tubing if tubing has .7" OD - $62 - [2](note: special order, but 100' sections are in stock). OD is .712".

- Compare to 3/4" tubing - $72 for 500' roll- [3], 1" OD. Based on surface area, the 3/4" option is about 20% cheaper, and less work to install. 3/4" should be used, as it saves 30% on installation length for the same power.

- Thus: Hillbilly tubing is 30 square feet or about 3 kW of heat capture per 500' coil. 500 feet *12 inches per foot *.7 in (square inches) = 30 square feet. For 3/4", that is 500*12/144 = 40 sf, or 4 sq meters. 4 kW per 500' coil.

- Amazon - 4 sf - $124 - [4]

- Evacuated tube - 5 sf - $179 + $230 ship - [5]

- Evacuated - $670 - 15 sf - [6]

DIY

- $250 cost for 4x8 foot finned collector with CPVC, which works comparably to finned aluminum collector - or $8/sf - [7]

Calculations

Area

Current greenhouse has 16' long rafters, for a 512 square foot area. Solar income on that area is 50 kW. 30% of this would be 15kW.

- 1500 feet of 1/2" tubing combines to 90 square feet - under 20%.

Conductivity

Surprise!

- Poly is as effective as copper in heat transfer in a simple water heater - [10] - see the Conclusion section.

System Goals

- Exchange Solar heat to aquarium water.

- Exchange heat without moisture with house via heat exchanger like [11]

Efficiency

Heat transfer is limited by the thermal conductivity of the pipe (PEH ~0.5 W/m K good for plastics).

Is high-pressure system ideal or is a low-pressure gravity system possible using black gutter(s) etc.?

Can water be mixed directly or is thermal mixing a bigger problem?

Can temperature be managed by pump control?

Reference Links

https://www.youtube.com/watch?v=0csXsRzrq2Y&t=5s Marcin Aquaponic Green House walkthrough