OSE 3D Printed Circuits: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 5: | Line 5: | ||

#This is not fine for small feature advanced microelectronics, but 2.54 mm components would work. | #This is not fine for small feature advanced microelectronics, but 2.54 mm components would work. | ||

#Soldering is quick for 2 wire components that touch each other. We can have the 3D print serve as a holding structure that makes soldering easy. | #Soldering is quick for 2 wire components that touch each other. We can have the 3D print serve as a holding structure that makes soldering easy. | ||

#2nd option: wires snap in place if printed from elastomer. Ga 10 or 8 solid copper - just snap it in. Circuit cover finishes circuit. Components become 100% reusable! | #2nd option: wires snap in place if printed from elastomer. Ga 10 or 8 solid copper - just snap it in. Circuit cover finishes circuit. Components become 100% reusable! | ||

#3rd connection option: Not also - if 2 leads are inserted into a hole, the hole can be plugged with a solid copper conductor for good contact. | |||

| Line 11: | Line 12: | ||

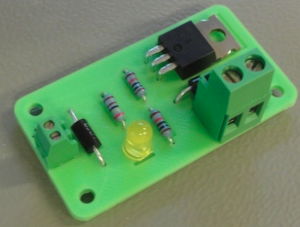

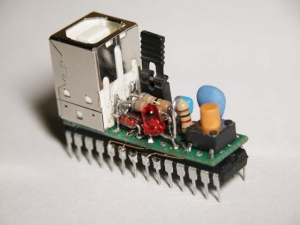

(Not OSE circuits. See [[Dead-Bug_Soldering]] and [[Circuits on Plastic]] for source.) | (Not OSE circuits. See [[Dead-Bug_Soldering]] and [[Circuits on Plastic]] for source.) | ||

=OSE Relevance= | |||

*In upcoming [[Incentive Challenge]] - we can require structure integrated circuits that are 3D printed in 3D. | |||

Revision as of 20:46, 28 April 2019

Concept: a 3D printed board serves as a structure for holding components so they are easy to solder. This can be described as dead-bug soldering with support structures. Note that Dead-Bug Soldering is useful for high frequency circuits - by the way.

- 3D print a circuit board with channels and physical infrastructure for holding all components.

- Bend the leads so they touch, and use wires to solder as needed. For through-hole components, this is fine.

- This is not fine for small feature advanced microelectronics, but 2.54 mm components would work.

- Soldering is quick for 2 wire components that touch each other. We can have the 3D print serve as a holding structure that makes soldering easy.

- 2nd option: wires snap in place if printed from elastomer. Ga 10 or 8 solid copper - just snap it in. Circuit cover finishes circuit. Components become 100% reusable!

- 3rd connection option: Not also - if 2 leads are inserted into a hole, the hole can be plugged with a solid copper conductor for good contact.

(Not OSE circuits. See Dead-Bug_Soldering and Circuits on Plastic for source.)

OSE Relevance

- In upcoming Incentive Challenge - we can require structure integrated circuits that are 3D printed in 3D.