Workshop Tools and Supplies: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

(→Tasks) |

||

| Line 1: | Line 1: | ||

=Tasks= | =Tasks= | ||

#Organize cordless drills for charging | |||

#Lay 6 white barrels by center posts for trash | #Lay 6 white barrels by center posts for trash | ||

#Verify 6 welders in good condition | #Verify 6 welders in good condition | ||

| Line 10: | Line 11: | ||

#Inventory number of welding gloves | #Inventory number of welding gloves | ||

#Lay out materials at work tables for the number of builds being done | #Lay out materials at work tables for the number of builds being done | ||

# | #Gasify burn the trash to eliminate workshop fire hazard | ||

#Move everything out of workshop to storage | |||

=Stocking= | =Stocking= | ||

Latest revision as of 17:17, 28 June 2019

Tasks

- Organize cordless drills for charging

- Lay 6 white barrels by center posts for trash

- Verify 6 welders in good condition

- Check out the bandsaw for working order and cooling fluid

- Inventory number of working abrasive cutoffs

- Inventory number of working welding helmets

- Inventory number of working 5A grinders

- Inventory number of working 11A grinders

- Inventory number of working 15A grinders

- Inventory number of welding gloves

- Lay out materials at work tables for the number of builds being done

- Gasify burn the trash to eliminate workshop fire hazard

- Move everything out of workshop to storage

Stocking

Common workshop tools that need to be stocked regularly:

- Abrasive metal cutoff saw - [1]

- 5A grinder - [2]

- 11A grinder - [3]

- 15A grinder - [4]

- 5 mm hex key - for 3D printers - [5]

- Vice grips

- Pipe wrench

- Adjustable wrench

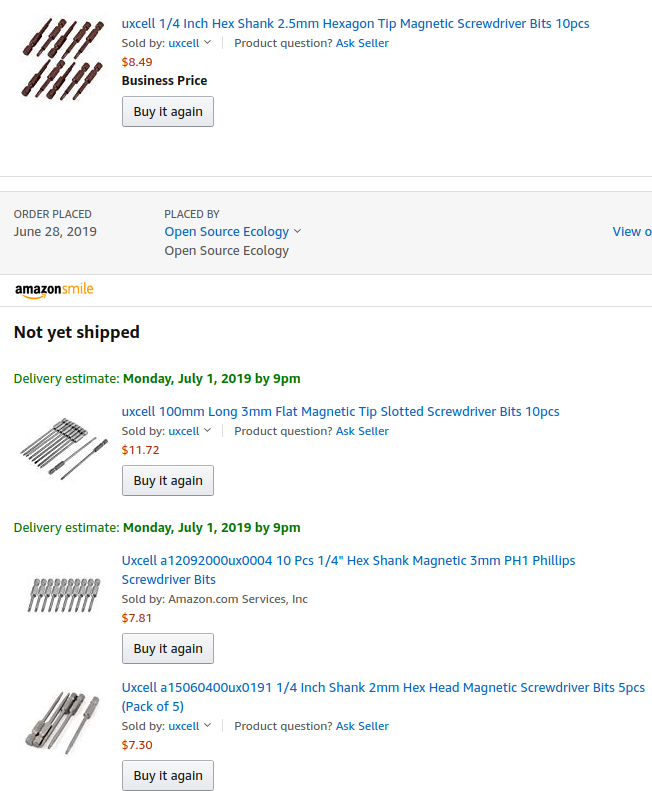

Bits from Amazon