3D Printer Workbench Work Proposal: Difference between revisions

| Line 28: | Line 28: | ||

* Add documentation | * Add documentation | ||

** Increased documentation on existing patterns | ** Increased documentation on existing patterns | ||

** Instructional on how to modify the FreeCAD 3D Printer Workbench for different CAD insertion - for example if someone wants to modify the extruder to add more details | |||

* Valuable refactors to existing [https://github.com/gbroques/ose-3d-printer-workbench ose-3d-printer-workbench] for making the below proposed architecture possible: | * Valuable refactors to existing [https://github.com/gbroques/ose-3d-printer-workbench ose-3d-printer-workbench] for making the below proposed architecture possible: | ||

Revision as of 22:14, 3 May 2020

Problem Statement

Designing 3D printer variants with pre-designed OSE parts and modules in FreeCAD is time-consuming and cumbersome.

Solution

Develop a FreeCAD workbench to streamline the design of 3D printer variants using pre-designed OSE parts and modules.

Proposal

General Requirements

- Support OSE Linux and FreeCAD 16

- If we can support 18 while not at the expense of 16, then great.

- Keep file size of parts low. See File Simplification for details.

- See further details in proposal.

Phase 1 Accomplishments (Feb 1st - May 1st 2020)

The 3D printer workbench allows for rapid design (5 minutes) of a 3D printer with any size frame, angle frame size, 3D printer corner size, axes, heated bed, and extruder - allowing the user to produce a design and to generate a cut list for metal rods and steel angle, as well as to generate the CAM files (STLs) for the 3D printed corners.

This allows for full flexibility of rapid design, turning the design process of any new configuration (frame size, angle iron size, 3D printed corner size) from a 24 hour+ project by skilled designers to a 5 minute project doable by novices. This is a great example of how custom, engineered design can be performed by non-experts, thereby taking a great leap towards democratized technology.

Phase 2 (Second 90 day iteration)

- Goal: Increase replicability of work accomplished in phase 1 (first 90 day iteration) to help OSE create FreeCAD design workbenches for all of its machines by 2028.

Deliverables

- Add more unit tests and increase code coverage of ose-3d-printer-workbench

- At the time of writing, current code coverage is 65%

- We aim to increase code coverage to 90 - 100%

- Add documentation

- Increased documentation on existing patterns

- Instructional on how to modify the FreeCAD 3D Printer Workbench for different CAD insertion - for example if someone wants to modify the extruder to add more details

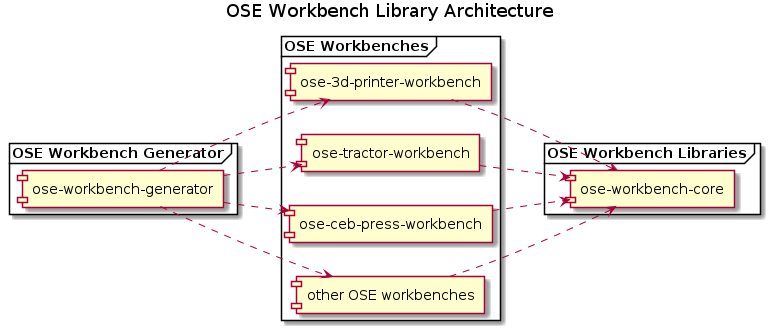

- Valuable refactors to existing ose-3d-printer-workbench for making the below proposed architecture possible:

ose-workbench-generatorusing a project scaffolding tool like cookiecutter or yeoman to quickly generate new workbenches with requisite files and structure needed to reduce barrier to entry.ose-workbench-corelibrary encapsulating functionality common to all OSE workbenches (will be withinose-3d-printer-workbenchinside ofose3dprinter.app.corepackage, but designed to be ported out into a separate repo and project later)

Stretch Goals: YouTube tutorial video series on FreeCAD Workbench Python Programming.

Existing Work

There was a similar effort around late 2017 to early-to-mid 2018 by Steven Kaiser and Ruslan Krenzler with the D3D Workbench and Piping Workbench.

The D3D workbench was merely a start, and it so far has a frame only, but made of PVC pipe, which is not our main branch of development. Though, it's useful for anyone wanting to build with PVC.

This proposal is for a new branch of development related to the idea of a OSE 3D Printer FreeCAD workbench starting in early 2019.