Backlash: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

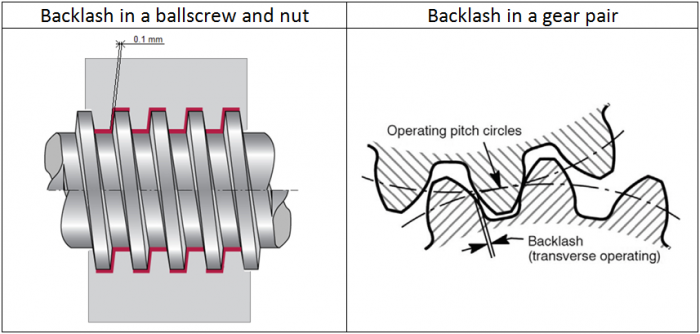

Backlash, also referred to as play, lash or slop, is a gap between two parts in a mechanism causing lost motion and increased wear. Some amount of backlash is unavoidable in nearly all reversing mechanical couplings, although its effects can be negated or compensated for. In many applications, the theoretical ideal would be zero backlash, but in actual practice some backlash must be allowed to prevent jamming. There are cases where some backlash is desired to allow for lubrication, manufacturing errors, deflection under load, and thermal expansion. | |||

[[File:Backlash.png|700px]] | |||

=Notes on backlash= | |||

*Gears compared with HTD 5 mm pitch 15 mm wide 24T pulleys [https://www.chiefdelphi.com/t/belts-vs-gears/159650/10] | *Gears compared with HTD 5 mm pitch 15 mm wide 24T pulleys [https://www.chiefdelphi.com/t/belts-vs-gears/159650/10] | ||

*Belts may appear cheaper than chain but maintenance cost is higher [https://www.quora.com/Why-would-you-use-a-belt-drive-instead-of-a-chain-drive] | *Belts may appear cheaper than chain but maintenance cost is higher [https://www.quora.com/Why-would-you-use-a-belt-drive-instead-of-a-chain-drive] | ||

*'''Excellwnt thread on stretch data for steel vs nylon belted belts.''' Kevlar is similar to steel. Stretch is about 0.2% per 20lb of force. [https://community.carbide3d.com/t/belt-stretch-and-stepper-holding-measured/18480/106]. Steel has 2x stretch. | *'''Excellwnt thread on stretch data for steel vs nylon belted belts.''' Kevlar is similar to steel. Stretch is about 0.2% per 20lb of force. [https://community.carbide3d.com/t/belt-stretch-and-stepper-holding-measured/18480/106]. Steel has 2x stretch. | ||

Latest revision as of 13:27, 1 October 2022

Backlash, also referred to as play, lash or slop, is a gap between two parts in a mechanism causing lost motion and increased wear. Some amount of backlash is unavoidable in nearly all reversing mechanical couplings, although its effects can be negated or compensated for. In many applications, the theoretical ideal would be zero backlash, but in actual practice some backlash must be allowed to prevent jamming. There are cases where some backlash is desired to allow for lubrication, manufacturing errors, deflection under load, and thermal expansion.