Steam Engine Build/Base Plate: Difference between revisions

Jump to navigation

Jump to search

(Created page with "{{Category=Steam Engine}} Steam Engine Build Instructions =Description= A heavy plate (1.0" thick) is used to provide a solid base for the steam engine and the crankshaft a...") |

No edit summary |

||

| Line 7: | Line 7: | ||

=CAD= | =CAD= | ||

[[Image:cad-base-plate.png]] | |||

=Drawings= | =Drawings= | ||

Latest revision as of 17:05, 13 July 2011

Main > Energy > Steam Engine

Steam Engine Build Instructions

Description

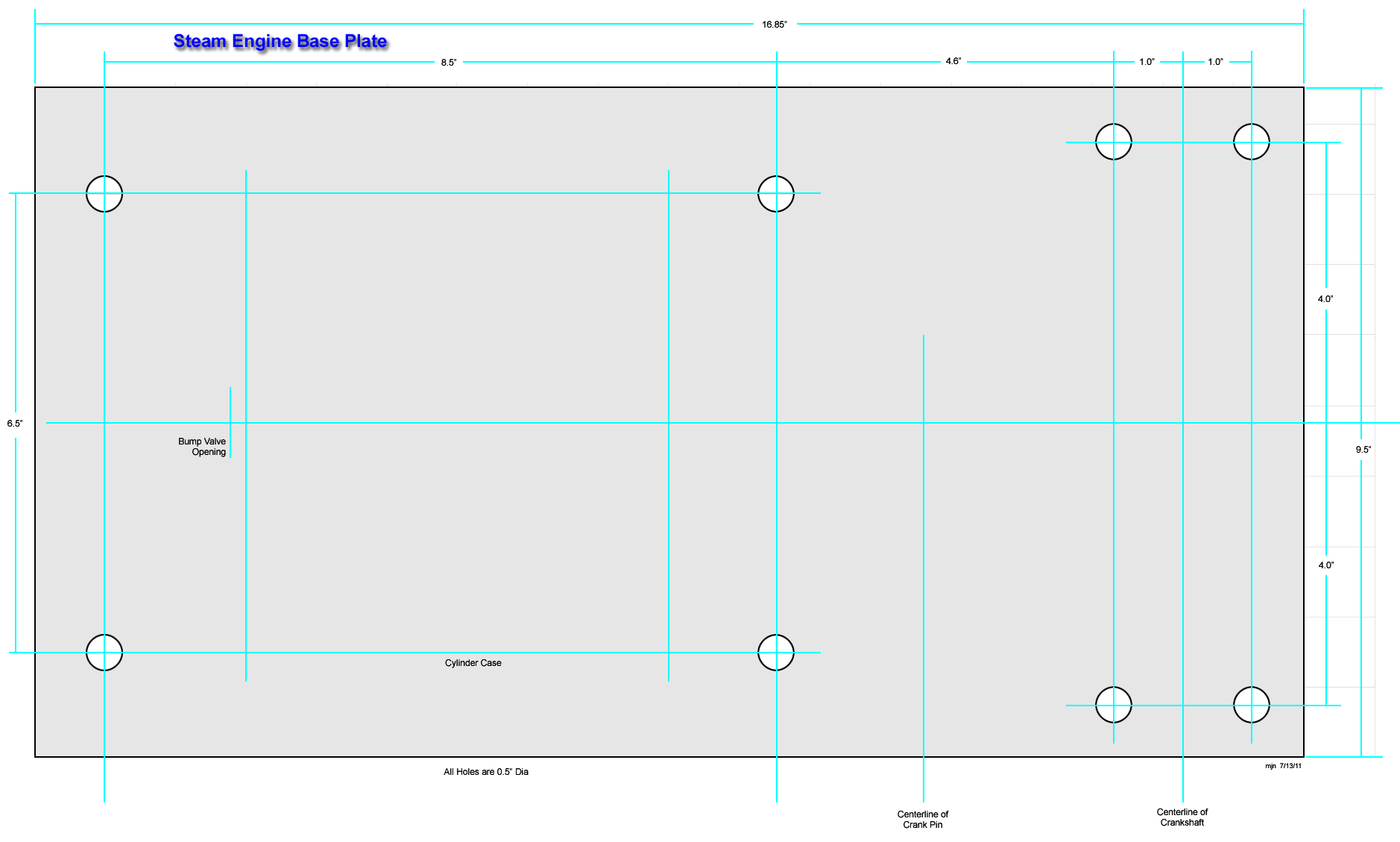

A heavy plate (1.0" thick) is used to provide a solid base for the steam engine and the crankshaft assemblies. This plate should be further attached to a massive sub-base, such as a concrete slab.

CAD

Drawings

Instructions

Using 1.0" thick steel plate:

- Cut a rectangle 17" by 9.5" (exact dimensions are unimportant)

- Drill four holes to bolt the engine assembly to the plate:

- Each hole is drilled and tapped to receive a half inch bolt

- Space centers 6.5" by 8.5" apart.

- Drill four holes to bold the crankcase assembly to the plate:

- Each hole is drilled and tapped to receive a half inch bolt

- Space centers 2.0" by 8.0" apart.

- Offset the crankcase holes from the engine assembly by 4.6"

Alignment of the crankshaft assembly with the engine assembly has two critical points:

- Center line of engine and connector rod must be centered on the crank pin.

- Amount of steam let into the engine is determined by the crankshaft offset (4.6"), though this can be fixed by adjusting the length of the bump pins.