Tom: Dallas Log: Difference between revisions

Tom Griffing (talk | contribs) |

Tom Griffing (talk | contribs) |

||

| Line 36: | Line 36: | ||

* It is Not an abrasive saw, but cuts with carbide teeth. The result is that freshly cut steel is cool to the touch. The secret to long blade life: Don't apply too much downward pressure - use just one hand lightly so it spews a few sparks at a time. One review noted this and claims that the blade will yield thousands of cuts if not forced. Excessive downward pressure breaks the carbide teeth and quickly ruins the blade. Also: make sure the steel to cut is securely clamped to prevent shifting during the cut. | * It is Not an abrasive saw, but cuts with carbide teeth. The result is that freshly cut steel is cool to the touch. The secret to long blade life: Don't apply too much downward pressure - use just one hand lightly so it spews a few sparks at a time. One review noted this and claims that the blade will yield thousands of cuts if not forced. Excessive downward pressure breaks the carbide teeth and quickly ruins the blade. Also: make sure the steel to cut is securely clamped to prevent shifting during the cut. | ||

* | * Specs: | ||

** Motor: 15 Amp, 4 HP | |||

** Blade: 14", 70 tooth, carbide tips | |||

** Large capacity cuts: 5-3/16" round & 4-1/2" x 6-1/2" rectangular | |||

** Patented quick fence and quick lock vise for securing steel to cut | |||

** 4 times faster than chop saws, 8 times faster than band saws | |||

* Video of cutting the initial 1/4" x 2" x 2" angle iron: | |||

::{{YoutubePopup|rqbLuiwmMt4||powercube-window}} | ::{{YoutubePopup|rqbLuiwmMt4||powercube-window}} | ||

Revision as of 11:37, 24 October 2011

Notes on My OSE Objectives

- First of all: I have a background in R&D hardware and software development. I also am highly interested in this line of work.

- The time I spent in Missouri on the Dedicated Project Visit was inspiring. I went there with the idea that there should be a profitable business model in the OSE product development and production.

- If not already apparent, after returning from the OSE Project Visit, I decided to get into OSE production by building a Power Cube and a LifeTrac in Dallas. The time in Missouri was an introduction and this would provide a "hands on" understanding of the fabrication process for myself.

- Following that, I plan to do some OSE promotion in the Dallas area and test the market for demand for OSE products.

- If demand is sufficient, set up shop to fabricate and refine OSE machines as kits or turnkey machines.

- Of course, this would require "giving back" to OSE in the form of improvements in design, documentation and parts sourcing. This is part of the Open Source model with which I am very familiar.

- Toward that end, I have continued documenting the Power Cube, LifeTrac and CEB press as well as corresponding with Marcin about design changes. I have also shared ideas with a friend in the DFW metroplex who is interested in helping in this endeavor. We've amassed most of the tools and equipment we'll need for production. I'm ready to forgo regular work and do this full time if I find sufficient demand.

- The necessary parts have either arrived or are on order for a Power Cube.

- I continue to work with the LifeTrac CAD designer toward completing the documentation necessary to order and build a LifeTrac, as this will be necessary after completion of the Power Cube.

- I have been looking for "an appropriate" place to set up shop for fabrication. Initially, we will use my friend's garage, but that will quickly change for security, privacy and personal reasons.

- One of the unknown challenges about OSE machines is the demand and the need for marketing. It would be great if overwhelming demand were already present, but I have yet to see it and don't expect it to be that easy. So, we must develop a means of developing demand.

October 19 - Wednesday

- Received the last two components: The oil cooler and the shaft coupler. Notified the vendor that the keystock is missing for the engine shaft - it should arrive soon. Hooray! ready to build (after the steel is acquired)!

October 16 - Monday and Tuesday

- OK ... It's been a while since the last update, but I've been making progress.

- Angle Iron for Power Cube and Jig cut. Bottom frame for Jig complete need to weld upper part.

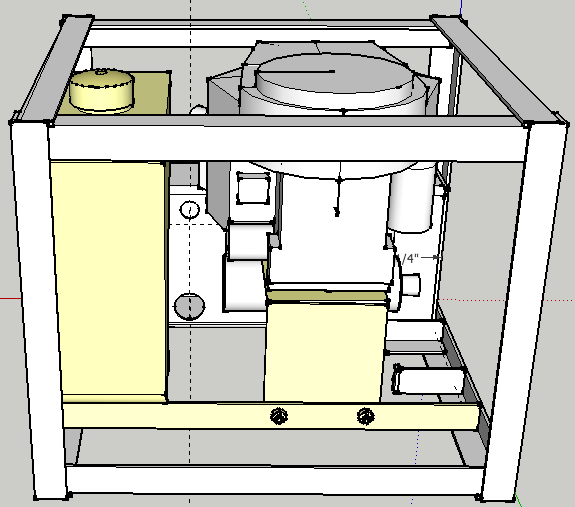

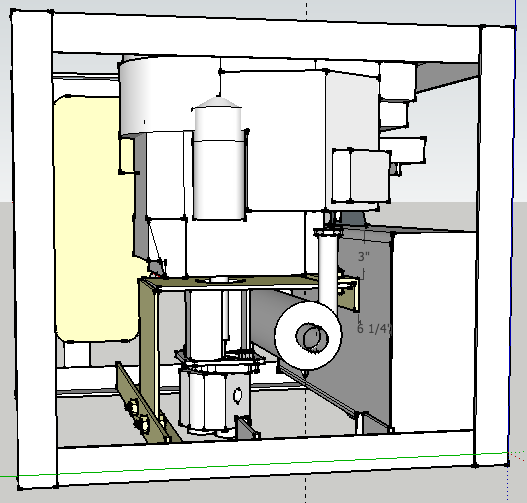

- Worked out new geometry for Power Cube using new muffler, fuel tank and pump support:

- Planning on securing remaining steel and fabricating soon.

October 9 - Sunday

- Finally got started - chopped up angle iron using my new saw, the DeWalt DW872 14 inch Multi Cutter Saw:

- Amazon sells the saw for $441.99: http://www.amazon.com/DEWALT-DW872-14-Inch-Multi-Cutter-Saw/dp/B0000302QS/ref=sr_1_1?ie=UTF8&qid=1319454779&sr=8-1, but I bought mine used for $125. The blade was slightly dull, sharpening cost an extra $20. New blades cost $92.41 at Amazon.com.

- It is Not an abrasive saw, but cuts with carbide teeth. The result is that freshly cut steel is cool to the touch. The secret to long blade life: Don't apply too much downward pressure - use just one hand lightly so it spews a few sparks at a time. One review noted this and claims that the blade will yield thousands of cuts if not forced. Excessive downward pressure breaks the carbide teeth and quickly ruins the blade. Also: make sure the steel to cut is securely clamped to prevent shifting during the cut.

- Specs:

- Motor: 15 Amp, 4 HP

- Blade: 14", 70 tooth, carbide tips

- Large capacity cuts: 5-3/16" round & 4-1/2" x 6-1/2" rectangular

- Patented quick fence and quick lock vise for securing steel to cut

- 4 times faster than chop saws, 8 times faster than band saws

- Video of cutting the initial 1/4" x 2" x 2" angle iron:

October 3-4 - Monday and Tuesday

- Finally purchased angle iron for the Power Cube. Hope to start chopping and welding the frame soon.

- Still waiting on items from Sweiger Shop: Shaft coupling and oil cooler.

- Corresponded with Andrew about his progress and he does have questions about the designs and about the changes I have documented in my Blog entries.

- Began a new contract, doing Linux system administration for a large telecom company here in the DFW metroplex. Together with all my other activities, this may slow Power Cube construction.

September 28-29 - Wednesday & Thursday

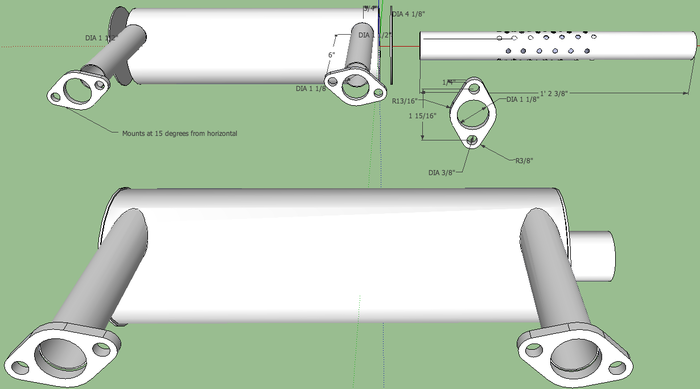

- Received the fuel tank, solenoid and used Sketchup to draw the muffler - should anyone need its dimensions:

September 27 - Tuesday

- Worked on the Power Cube R&D section, added information about the different couplings, what works, what doesn't work and the preferred options.

- Received the muffler today:

September 26 - Monday

- Not much here, as I'm mostly waiting for delivery of ordered items.

- Did some work on the Power Cube documentation.

- Spent time researching real estate websites - found an interesting property nearby that may serve as a fabrication facility. This has been a challenge, finding suitable workspace for OSE development with land to serve as a "proving ground" and an appropriate building that is not too far from my home in Dallas.

September 23 - Friday

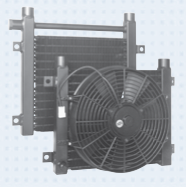

- Ordered the hydraulic oil cooler and shaft coupling from Sweiger Shop. I was hoping to hear from one other cooler supplier, but they didn't return my message.

- Ordered a kit with fan & thermostat switch from Amazon.com - with a couple of caveats:

- I believe the cooler fin dimensions are 12" by 20" and the fans come in 10, 12, 14 and 16 inch sizes. I decided to go with the 14" cooler as it has 33% more air movement than the 12" fan and the mounting bolts appear to be 12" apart. This will "waste" 1" of air movement from the fan edges, but I believe it will provide better cooling and mounting.

- The 14" fan kit has two options for the thermostat: one that is immersed in the oil and the other clips to the radiator fins. I chose the latter, as I didn't want to deal with the extra plumbing to connect a 3/8" probe in a 3/4" pipe. The 12" fan kit didn't have the option for the fin mounted thermostat.

September 22 - Thursday

- Got radical today and ordered a 5.5 gallon fuel tank from Surplus Center and also the solenoid I neglected in prior order. The larger fuel tank departs from original designs, but it addresses the limitation of the smaller fuel tank.

- Also ordered a Briggs and Stratton muffler. The is a departure from the original Power Cube design, but I wanted it for two reasons:

- Study the muffler design in case we decide to create an OSE muffler

- This one should be significantly quieter than the original design and will only send exhaust out one side - and away from the plastic fuel tank

- The alternate fuel tank may require relocating the ports in the hydraulic tank, but it will provide more than 3 times the fuel capacity.

- The commercial muffler may also present an installation challenge, but it will provide significantly quieter operation.

- I've been looking at cooler options and will order from Sweiger Shop, along with a shaft coupling.

- I found a cooling fan and thermostat switch from Amazon for less than 50 USD:

September 21 - Wednesday

- Updated CEB BOM with electronic parts for building the Arduino Breakout board.

- This Printed Circuit Board is no longer available completely built. It comes as a bare board and parts must be ordered separately and the board must be assembled.

- Proposed higher capacity fuel tank for Power Cube - 5.5 gallons and added the info the to R&D section.

September 20 - Tuesday

- Logging will likely slow to a crawl, as I will be starting a full-time job as a Linux administrator with a national telecom company. Of course, my side jobs of teaching Tai Chi, Kung Fu and teaching a class at Richland College are already having that effect.

- Worked on resolving which oil cooler to order - Talked twice with a Dallas supplier who has coolers, but they have not given a price as yet.

September 19 - Monday

- Took a few days' break from logging.

- Reorganized BOM Steel sheet to match the order of the 2D Fab document and sent the author questions about discrepancies.

- Surplus Center called and said they only have 5.5' of the 6' hydraulic suction hose I ordered - they said they would send it all, but only charge for 5'.

- Spoke with Sweiger Shop about coolers and coupling and they are responsive. Here is their reply:

The oil cooler is $208.00 plus freight for 1 unit. If you order 10 at a time the price goes down.

We don't know exactly what the freight will be yet to us or to your zip code.

The cooling fan for this unit is $133.64 each. You can put 2 fans on this if you want.

The adjustable control is $30.54 each.

The coupling: 5/8 hub--$6.45

1 1/8 hub--$6.45

connector--$8.86

offset keystock-- $5 each

labor to weld together= $6

total= $32.76

I am checking on a local Dallas-based supplier for coolers and will make a decision when I hear from them. BTW: Sweiger Shop is a great outfit that supplies steel and other items for OSE. They can take orders over the phone and ship light items (not steel). Here is their contact info:

Sweiger Shop, Inc. 5502 N.E. Dallas Rd. Weatherby, MO 64497 Phone: 816-449-2292 E-Mail: mocop1120@yahoo.com

- Corresponded with Marcin about a new engine/pump support design. Objectives were to retain engine shaft for warranty and to permanently weld nuts in place to simplify pump mounting. This requires longer spacers between the pump plate and the engine plate - and therefore stiffer support between the two. Using angle iron instead of bolts shrinks the size of the pump plate by 3" and therefore makes room for the muffler I want to add. Here is my proposed design:

September 16 - Friday

- Continued documenting and digging out details about the best procedure for building the engine/coupling/pump assembly.

- Got copy of E-Mail from Andrew, who will be building a Power Cube and LifeTrac. How exciting! Sent message with links to log and manufacturing directions.

- UPS delivered the engine today and it had some damage to the plastic housing, but otherwise looks OK. Contacted the sender asked how to proceed.

- Good news: This engine has an "Electronic Fuel Management System" and does not have a manual choke. This will simplify things.

- Composing list of Misc things to get to test engine:

- 12 V Battery

- Gas container and gasoline

- Oil - 2 quarts 10W-30

- 3 feet: 1 Gauge wire & ring connectors (or copper tubing)

- 2 feet: 1/4" rubber fuel line

September 15 - Thursday

- Spent more time reviewing the BOM lists and found many more updates. Called Surplus Center and they changed several items in the order before it was released for shipping.

I will submit an updated order list when I receive it.Already updated. - While on the phone with SurplusCenter, I asked them about couplings and gave them the shaft sizes for the Power Cube - they said it would come in 3 pieces and cost 52 dollars total, so I added this to the order as well.

- Marcin said: Our experience with spider couplings and hytrel showed that they don't last more than 40-100 hours, so we went to solid couplings. The plastic wears out.

- OK - With that information, I cancelled the coupling from the order and will be going with a custom fixed coupling instead.

- Called a local vendor for hydraulic coolers and found a company here in Dallas that sells with or without fan and thermostatic switch. Looking at the photo made me think that if we used their fan, we could do without the expanded steel protecting the oil cooler fins - but at what cost? Waiting on reply from vendor.

September 14

- Spent time studying the documentation and design drawings for the LifeTrac tractor and compared them against the old BOM for steel parts. Did lots of updating and send requests for revision to the current maintainer - Will. Last correspondence said he is packing up in England and soon traveling to Factory-E-Farm in Missouri.

- Spent hours analyzing discrepancies between the BOM part list and the actual parts for the Power Cube - found lots of differences and made some adjustments for design updates and parts available from the vendor. Will update BOM tomorrow accordingly. Finally, got the first round ordered. Here is the order:

1 9-1788-B 0.976 cu in PRINCE SP20B16A9H2R HYD 187.95

1 9-7290-100 1-1/2" NPTM TO 1" NPTF 14 GPM TANK S 19.95

3 9-5500-12-12 3/4 NPTM TO 3/4 NPTM 90 ELBOW 15.00

1 928-C 3/4" QUICK COUPLER S40-6 F/F 25.95

1 9-7843-24 1-1/2" NPT FORGED WELD-IN TANK FLANG 4.50

1 9-7843-4 1/4" NPT FORGED WELD-IN TANK FLANGE 2.40

1 455-AA HOSE BARB 1/4" X 1/4" NPTM 4244-4-4 1.25

6 9-1279 1" HYD SUCTION/RETUN HOSE (SOLD BY T 30.00

1 951-2212 3/4" X 12" JIC 12F X JIC 12F 3000 PS 15.00

1 9-059 3/4" NPT 20 GPM FA1200-10 RETURN FIL 17.95

1 9-4404-16-16 1 HOSEBARB TO 1 NPTM ADAPTER 4404-16 6.00

4 9-5404-12-12 3/4 NPT HEX NIPPLE 10.60

1 9-7957-12 3/4" NPT PLASTIC TANK BREATHER 4.49

1 9-5605-12-12-12 3/4 X 3/4 X 3/4 NPTF TEE 7.00

1 9-5404-4-4 1/4 NPT HEX NIPPLE 0.95

1 9-6314 1/4" NPT QUICK COUPLER S40-2 17.95

2 9-7843-12 3/4" NPT FORGED WELD-IN TANK FLANGE 5.50

1 9-4604-16-12 1 HOSEBARB TO SAE 12M ADAPTER 4604-1 7.89

1 9-2501-12-12 JIC 12M x 3/4 NPTM 90 ELBOW 5.59

1 9-2403-12-12 JIC 12M x JIC 12M UNION 2.75

1 9-6505-12-12 JIC 12F TO 3/4 NPTM SWIVEL 6.00

Total $: 394.67

____________________________________________________________________________

Order Recap:

Total Product $: 394.67

Net Product$: 394.67

Shipping: 15.81

Sales Tax: 0.00

Insurance : 2.00

Grand Total: 412.48

____________________________________________________________________________

- Note that when searching for items, you must be creative. For example, a "Hose Barb" is sometimes spelled "HOSEBARB" and isn't found by searching for "hose" or "barb". Try multiple ways of searching or just call the vendor.

- Immediately after pressing the confirm button, I realized that I was missing a part or two, but that they should be easy to find in Dallas, but it will mean another trip to a vendor.

September 13

Since my return from the Dedicated Project Visit, I have been continuing my documentation efforts on the Power Cube. The documentation is critical when ordering parts and steel, as I want to have everything necessary, but not be short either.

I have also collected a set of tools for building Power Cubes. This video shows some of the tools:

- Tools collected so far

- Oxy-Acetylene cutting torch, tanks, hose, regulators, cart (Used: $400)

- Heavy Duty Metal cutting chop saw (Used: $125 + $20 to re-sharpen carbide blade)

- 1/2" Hand Drill

- 7" Angle Grinder ($70 at Northern Tool - 5 Yr in-store warranty)

- 4" Angle Grinder (Used: $30)

- Shop Vacuum (Used: $15)

- 3 pair Vise Grip pliers - to clamp metal for welding

- Socket Set

- 2 Crescent wrenches

- Face shield for grinding

- Eye protection

- Other tools not shown in the video include:

- TIG Welder

- Safety Equipment (steel toe boots, welding hood, welding jacket, hearing protection)

- Drill press

- Paint sprayer

Ordered Engine

Scoured the web for sources on engines and finally came across Small Engine Suppliers and ordered a suitable 28 HP model:

- Order:

--PRODUCT INFORMATION-- Quantity: 1 Product: Briggs & Stratton 49M777-various 28 HP Professional Series ($ 699.95 ea.) Options: Cost (each): $ 699.95 Item Subtotal: $ 699.95 Wt. each: 100 Total Wt.: 100 Product ID: 04390 Whse: sed SUBTOTAL: $ 699.95 SHIPPING: $ 74.95 Agreed to terms TOTAL: $ 774.90

- Next step: Order Power Cube parts and steel