CEB Press/Manufacturing Instructions/Wide Cylinder Supports: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

<html><iframe src="http://sketchup.google.com/3dwarehouse/mini?mid=31ebd3ea006a79211211da1f85706ccd&etyp=sw&width=400&height=300" frameborder="0" scrolling="no" marginheight="0" marginwidth="0" width="400" height="300"></iframe></html> | |||

=Tools Required= | =Tools Required= | ||

*Welder | *Welder | ||

Latest revision as of 02:45, 16 December 2011

Tools Required

- Welder

- Torch

- Punch with 3/4" dies

- Angle Grinder

- Speed square

Materials Required

Monster CEB

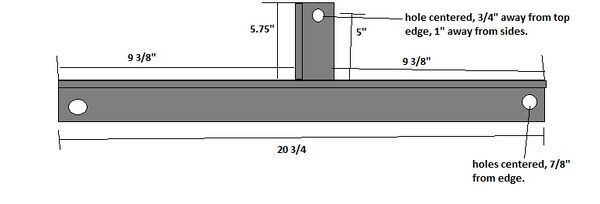

- 6" Light (1/4") U-Channel: 41.5" total; Wide cylinder support horizontal: 20 3/4" (2)

- 2"x2"x1/4" angle: 11.5"; Wide cylinder support verticals: 5.75" (2)

- 3/4" Steel Nuts-(2)

- 3/4" Galvanized Nuts-(2)

Normal CEB

- 2"x2"x1/4" Angle: 53"

- Wide cylinder support horizontal: 20 3/4" (2)

- Wide cylinder support verticals: 5.75" (2)

- 3/4" Steel Nuts-(2)

- 3/4" Galvanized Nuts-(2)

Diagrams

Fabrication Instructions

- For the "Normal CEB," torch 3/4" holes in the angle for the cylinder supports in the same manner as with the horizontal members.(19" apart, 3/4" diameter)

- For the monster, don't worry about the holes, you'll mag-drill them later.

- Weld the 2"x2" angle (5.75") centered and squared on one side of the U-Channel(for "monster") or angle (for "normal", weld it to the side without the holes).

- Torch a hole (3/4" for "normal") (1" for "monster") away from the end of the 2"x2" for a 3/4" bolt and grind it clean.

- Place a steel nut over the hole and insure it is clear for a bolt and flush.

- Weld the nut in place.

- Put a galvanized nut on a 3/4"x2.5" bolt and thread through the welded nut on each side.