CEB Press/Manufacturing Instructions/Soil grate: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 27: | Line 27: | ||

*[2] 3/4" Steel nuts | *[2] 3/4" Steel nuts | ||

= | =Steps= | ||

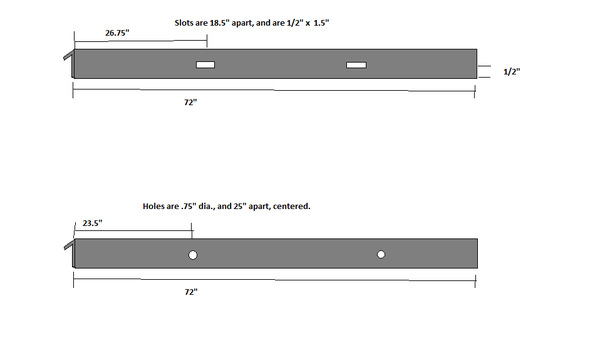

*Torch the holes in the two 6' angles as shown, and grind off all the slag. | |||

[[Image:gratetorch.png|600px|Where to torch the holes on the grate]] | [[Image:gratetorch.png|600px|Where to torch the holes on the grate]] | ||

*Using the welder, weld 1/2-13 nuts to the 2 round holes of one of the 6' angles on the outside surface. | |||

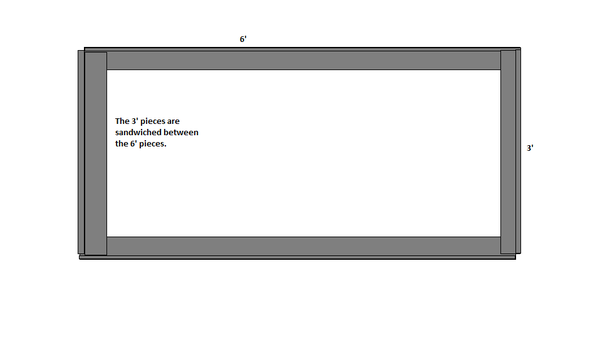

*Weld the two 3' and two 6' angles together to make the frame. The short pieces are sandwiched between the long pieces as shown. Make sure the holes you torched are on the outside, ie. not where the rebar will be welded on top of them. | |||

[[Image:weldgrate.png|600px]] | [[Image:weldgrate.png|600px]] | ||

*Weld all of the rebar inside of the frame. It would help to find some 1.5" spacers laying around the shop so you can place them between the rebars quickly and be sure they are square. Nuts and hydraulic fittings might be the right size. | |||

[[Image:grate.gif|The grate]] | [[Image:grate.gif|The grate]] | ||

*Weld the cross support (the 1/4 x 2 flatbar) in centered and perpendicular to the plane of the frame. | *Weld the cross support (the 1/4 x 2 flatbar) in centered and perpendicular to the plane of the frame. | ||

Revision as of 05:01, 23 December 2011

Part Information

- The soil grate prevents overly large chunks of soil from entering the hopper.

- The soil grate is mounted to the hopper supports and the grate supports.

Tools Required

- Welder

- Angle Grinder

- Clamps

- Torch

Materials

- [2] 1/4”x2”x2” angle, 6'

- [2] 1/4”x2”x2” angle, 3' (2)

- 1/4”x2” bar, 71.5”

- [33] Steel Rebar, 1/2" diameter and 3' length

- [2] 3/4" Steel nuts

Steps

- Torch the holes in the two 6' angles as shown, and grind off all the slag.

- Using the welder, weld 1/2-13 nuts to the 2 round holes of one of the 6' angles on the outside surface.

- Weld the two 3' and two 6' angles together to make the frame. The short pieces are sandwiched between the long pieces as shown. Make sure the holes you torched are on the outside, ie. not where the rebar will be welded on top of them.

- Weld all of the rebar inside of the frame. It would help to find some 1.5" spacers laying around the shop so you can place them between the rebars quickly and be sure they are square. Nuts and hydraulic fittings might be the right size.

- Weld the cross support (the 1/4 x 2 flatbar) in centered and perpendicular to the plane of the frame.