CNCCMV2/Structure/Blocks: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 14: | Line 14: | ||

*All pilot holes to be tapped M5x0.8 should have a diameter of 4.5mm | *All pilot holes to be tapped M5x0.8 should have a diameter of 4.5mm | ||

=Fabricate Wide Template= | |||

* | |||

* | |||

=Fabricate Narrow Template= | |||

* | |||

* | |||

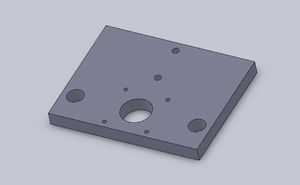

=Fabricate Platform= | =Fabricate Platform= | ||

Revision as of 16:31, 28 April 2012

Marking the Sleeve Bearing Mount Holes

- Mark 6.5mm from the circumference of the 18mm hole for each sleeve bearing mount hole.

- Drawing a centerline may be helpful to measure along.

Drilling the Leadscrew Nut Mount Holes

- Match drill the leadscrew nut mount holes from the leadscrew nut to the block while the leadscrew nut is fitted inside the block for superior alignment.

- After drilling each hole, tap it and screw in an M5 screw for secure mounting for drilling and superior alignment.

M5 Pilot Holes

- All pilot holes to be tapped M5x0.8 should have a diameter of 4.5mm

Fabricate Wide Template

Fabricate Narrow Template

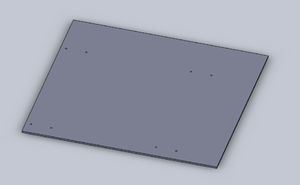

Fabricate Platform

- Qty=1

- Mark all holes using 2 datum edges in the L-shape.

- Drill all holes

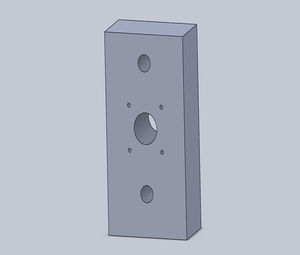

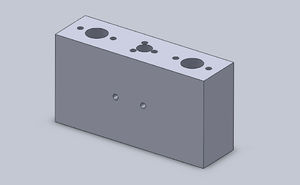

Fabricate X Major Block

- Qty=2

X Major Block 1

- Mark all holes for the first block, noting the datum edge orientation.

- Drill all marked holes for the first block, but for the stepper shaft hole use a 1/8" dia bit instead of 22mm.

- Check compatibility between the first block and the stepper motor.

- Tap the required holes.

- Drill the stepper shaft hole to its correct diameter AFTER all X and Y Blocks are complete.

X Major Block 2

- Mark all holes except the stepper mount and shaft holes.

- Drill all marked holes.

- Match drill the stepper mount and shaft holes from X Major Block 1 to X Major Block 2, using the 12mm dia 200mm lg support shaft for alignment of the support shaft holes.

- Check compatibility between the second block and the stepper motor.

- Tap the required holes.

- Drill the stepper shaft hole to its correct diameter.

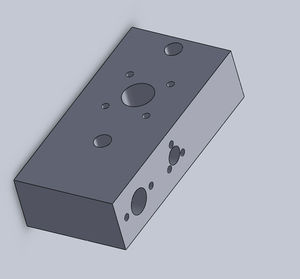

Fabricate X Minor Block

- Qty=2

X Minor Blocks 1 and 2

- Mark all holes except the 6.35mm dia leadscrew hole.

- Drill all marked holes.

- Match drill the leadscrew hole from X Major Block 1 (stepper shaft hole) to X Minor Blocks 1 and 2.

- Tap required holes.

Fabricate Y Major Block

- Qty=1

- Mark all holes except the leadscrew nut, leadscrew nut mount; use 1/8" bit for the stepper shaft hole.

- Drill all marked holes.

- Match drill the leadscrew nut hole from the X Major Block 1 (stepper shaft hole) to the Y Major Block, using a 12mm dia support shaft for alignment.

- Drill the leadscrew nut hole to its correct diameter.

- Match drill the leadscrew nut mount holes from the leadscrew nut to the Y Major Block, using the fit of the leadscrew nut inside the Y Major Block for alignment.

- Tap the required holes.

- Drill the stepper shaft hole to its correct diameter AFTER the Y Minor Block and Z Mount Block are complete.

Fabricate Y Minor Block

- Qty=1

- Mark all holes except the leadscrew nut, leadscrew nut mount, leadscrew, and upper support shaft holes.

- Drill all marked holes

- Match drill the leadscrew nut hole from the X Major Block 1 (6.35mm stepper shaft hole) to Y Minor Block, using a support shaft for alignment.

- Drill the leadscrew nut hole to its correct diameter.

- Match drill the leadscrew nut mount holes from the leadscrew nut to the Y Minor Block, using the fit of the leadscrew nut into the Y Minor Block for alignment.

- Match drill the leadscrew and upper support shaft holes from Y Major Block to Y Minor Block, using a support shaft for alignment.

- Tap the required holes.

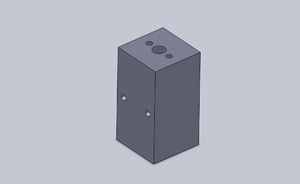

Fabricate Z Mount Block

- Qty=1

- Mark all holes except the leadscrew nut, leadscrew nut mount, upper support shaft, top rear mount, and bottom rear mount holes.

- Drill all marked holes.

- Match drill the leadscrew nut and upper support shaft hole from the Y Major Block (6.35mm stepper shaft hole) to the Z Mount Block.

- Drill the leadscrew nut hole to its correct diameter.

- Match drill the leadscrew nut mount holes from the leadscrew nut to the Z Mount Block using the fit of the leadscrew nut into the Z Mount Block for alignment.

- Match drill the top rear mount and bottom rear mount holes from the Z Major Block to the Z Mount Block AFTER the Z Major and Minor Blocks are complete.

- Tap the required holes after the top and bottom mount holes are drilled.

Fabricate Z Major Block

- Qty=1

- Mark all holes.

- Drill all marked holes, but use a 1/8" bit for the stepper shaft hole.

- Drill the stepper shaft hole to its correct diameter AFTER the Z Minor Block and End Mount Block are complete.

Fabricate Z Minor Block

- Qty=1

- Mark all holes except the leadscrew, front mount, rear mount, and one of the support shaft holes.

- Drill the marked holes.

- Match drill the leadscrew, front mount, rear mount, and the missing support shaft hole from the Z Major Block to the Z Minor Block, using a support shaft for alignment.

Fabricate End Mount Block

- Qty=1

- Mark all holes except the leadscrew nut, leadscrew nut mount, one of the support shaft, and the front mount holes.

- Drill all marked holes.

- Match drill the leadscrew nut and support shaft hole from the Z Major Block (6.35mm stepper shaft hole) to the End Mount Block, using a support shaft for alignment.

- Drill the leadscrew nut hole to its correct diameter.

- Match drill the leadscrew nut mount holes from the leadscrew nut to the End Mount Block using the fit of the leadscrew nut into the End Mount Block for alignment.

- Match drill the front mount holes from the Spindle Block to the End Mount Block AFTER the Spindle Block is complete.

- Tap the required holes after the front mount holes are drilled.

Fabricate Spindle Block

- Qty=1

- Match the mounting thru holes with End Mount Block

- Tap holes as necessary