CNCCMV2/Structure/Blocks

Jump to navigation

Jump to search

Marking the Sleeve Bearing Mount Holes

- Mark 6.5mm from the circumference of the 18mm hole for each sleeve bearing mount hole.

- Drawing a centerline may be helpful to measure along.

Drilling the Leadscrew Nut Mount Holes

- Match drill the leadscrew nut mount holes from the leadscrew nut to the block while the leadscrew nut is fitted inside the block for superior alignment.

- After drilling each hole, tap it and screw in an M5 screw for secure mounting for drilling and superior alignment.

M5 Pilot Holes

- All pilot holes to be tapped M5x0.8 should have a diameter of 4.5mm

Template-Component Clamping: Datum Edge Orientation

- When clamping templates and components for match drilling, ensure that the datum edges of the template are appropriately positioned relative to the component to be drilled.

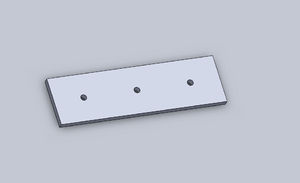

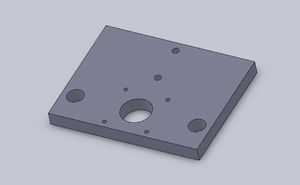

Fabricate Narrow Template

- Mark and drill.

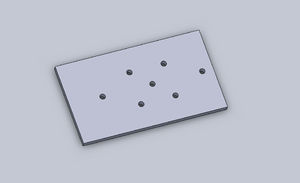

Fabricate Wide Template

- Mark datum lines for the Narrow Template.

- Match drill with the Narrow Template.

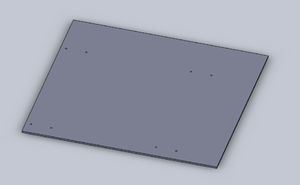

Fabricate Platform

- Qty=1

- Mark all holes using 2 datum edges.

- Drill all holes

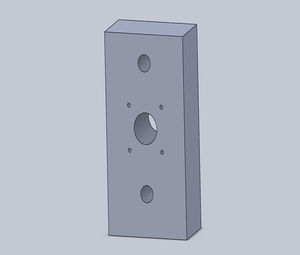

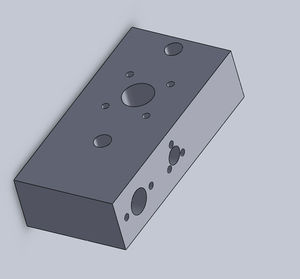

Fabricate X Block

- Qty=2

- Match drill with the Wide Template.

- Mark the remaining holes.

- Drill all holes to their appropriate diameters.

- Tap required holes.

- Qty=2

- Match drill with the Wide Template.

- Mark the remaining holes.

- Drill all holes to their appropriate diameters.

- Tap required holes.

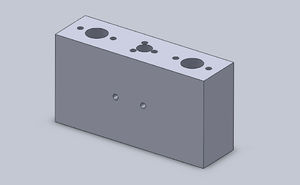

Fabricate Y Block

- Qty=1

- Match drill with the Narrow Template.

- Match drill with the Wide Template.

- Mark the remaining holes.

- Drill all holes to their appropriate diameters.

- Tap required holes.

Fabricate Z Mount Block

- Qty=1

- Match drill with the Narrow Template.

- Mark the remaining holes.

- Drill all holes to their appropriate diameters.

- Tap required holes.

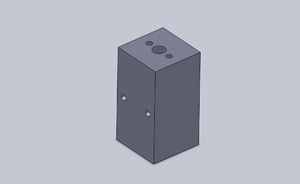

Fabricate Z Block

- Qty=1

- Match drill with the Wide Template.

- Mark the remaining holes.

- Drill all holes to their appropriate diameters.

Fabricate End Mount Block

- Qty=1

- Match drill with the Narrow Template.

- Mark the remaining holes.

- Drill all holes to their appropriate diameters.

- Tap required holes.

Fabricate Spindle Block

- Qty=1

- Mark all holes

- Drill all holes