Lathe Specifications: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 12: | Line 12: | ||

[[Image:Lathe.jpg]] | [[Image:Lathe.jpg]] | ||

'''Specifications''' | |||

*12" lathe | |||

*1/1000" accuracy via bearing tolerance and chuck tolerance | |||

*Heavy duty axial thrust acceptable, as determined by 3" shaft and bearings | |||

*Radial thrust determined by set screws on 2 bearings, with 2 extra full split collars | |||

[[Category:Specifications]] | |||

Revision as of 04:37, 2 March 2009

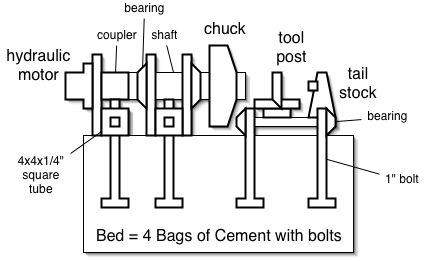

Fabrication and Cost

- Ease and low cost of fabrication is the primary goal, as a high-performance lathe is perhaps the most important tool in a workshop

- Construction consists of a concrete bed

- Cost is that of 4 bags of concrete for the bed, chuck, cross slide, and

- Motor cost is included in LifeTrac infrastructure

- Motor coupler to lathe shaft is machined

- Commercial chck is the main cost

- XY table constitutes a cross slide

- Tool post is fabricated

- 2" shaft constitutes a mounting surface for an xy table and for tail stock

- Feed-through shaft is present, but is only 1 foot deep

Specifications

- 12" lathe

- 1/1000" accuracy via bearing tolerance and chuck tolerance

- Heavy duty axial thrust acceptable, as determined by 3" shaft and bearings

- Radial thrust determined by set screws on 2 bearings, with 2 extra full split collars