Cold Saw/V1 Design Files/Swivel Plate: Difference between revisions

< Cold Saw | V1 Design Files

Jump to navigation

Jump to search

| Line 3: | Line 3: | ||

*'''Length: 457.2mm''' | *'''Length: 457.2mm''' | ||

*'''Width: | *'''Width: 203.2mm''' (Wide enough to fit the shaft blocks wide enough to support the drive assembly such that the blade is centered on the vise) | ||

*'''Thickness: 25.4mm''' | *'''Thickness: 25.4mm''' | ||

| Line 19: | Line 19: | ||

*'''Support Hole Rectangle: 30mm x 55mm''' | *'''Support Hole Rectangle: 30mm x 55mm''' | ||

*'''Support Hole Rectangle Positioning: Centered, | *'''Support Hole Rectangle Positioning: Centered, 140mm apart center to center.''' | ||

*'''Support Hole Notes: The Support holes must be positioned such that the blade is centered at the vise. The blade should be centered at the vise so that angled cuts are facilitated in both directions (angling to both left and right). The Support holes should also leave enough space between the Shaft Blocks such that a thrust washer and clamping shaft collar can fit in between (and be easily maintained).''' | *'''Support Hole Notes: The Support holes must be positioned such that the blade is centered at the vise. The blade should be centered at the vise so that angled cuts are facilitated in both directions (angling to both left and right). The Support holes should also leave enough space between the Shaft Blocks such that a thrust washer and clamping shaft collar can fit in between (and be easily maintained).''' | ||

Revision as of 16:48, 12 June 2012

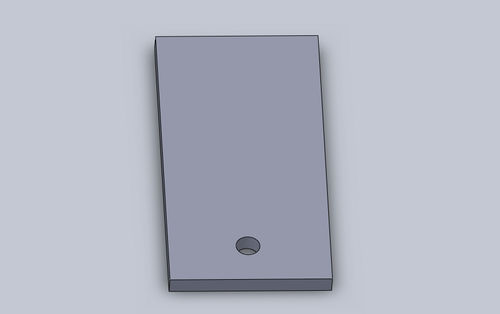

Swivel Plate

- Length: 457.2mm

- Width: 203.2mm (Wide enough to fit the shaft blocks wide enough to support the drive assembly such that the blade is centered on the vise)

- Thickness: 25.4mm

- Swivel Hole Diameter: 30mm

- Swivel Hole Along Length; 400mm from Edge

- Swivel Hole Spacing Along Width: Centered

- Support Hole Diameter: 12mm with 20mm dia 13 deep countersink

- Support Hole Rectangle: 30mm x 55mm

- Support Hole Rectangle Positioning: Centered, 140mm apart center to center.

- Support Hole Notes: The Support holes must be positioned such that the blade is centered at the vise. The blade should be centered at the vise so that angled cuts are facilitated in both directions (angling to both left and right). The Support holes should also leave enough space between the Shaft Blocks such that a thrust washer and clamping shaft collar can fit in between (and be easily maintained).

- 2D Image

- 3D CAD STP

- 2D Fabrication Drawing PDF

- 2D Fabrication Drawing DXF