Induction Furnace Conceptual Diagram: Difference between revisions

| Line 3: | Line 3: | ||

=Conceptual Diagram= | =Conceptual Diagram= | ||

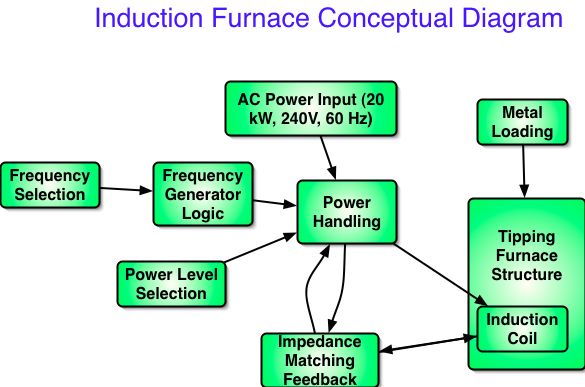

This is a conceptual diagram of the entire Induction Furnace system [[Image:induction_furnace.jpg]] from the [[Global Village Construction Set]]. The furnace is powered by 20 kW of 240VAC electricity from the [[LifeTrac]] generator. The entire system includes the power electronics, induction coil, and heating vessel - into which metal for melting is inserted. This diagram intends to document the relationship of functional components in the induction furnace system, as a basis for technical development of components and their integration | This is a conceptual diagram of the entire Induction Furnace system [[Image:induction_furnace.jpg]] from the [[Global Village Construction Set]]. The furnace is powered by 20 kW of 240VAC electricity from the [[LifeTrac]] generator. The entire system includes the power electronics, induction coil, and heating vessel - into which metal for melting is inserted. This diagram intends to document the relationship of functional components in the induction furnace system, as a basis for technical development of components and their integration. | ||

The electronics part should be adaptable to different metals and different metal melting coil geometries. Melting coils should also be modular, such that the power electronics can feed different coils. Basic functions include selection of heating frequencies, which are required for melting different metals or metal geometries. There should be a feedback in the electronics, where the amount of power given to the coil should match the quantity/geometry of metal being melted. | |||

[[Image:induction_concept.jpg]] | [[Image:induction_concept.jpg]] | ||

[[Category:Induction Furnace]] | [[Category:Induction Furnace]] | ||

Revision as of 16:38, 31 March 2009

See Metal_Melting_Furnace_Specifications for general application notes.

Conceptual Diagram

This is a conceptual diagram of the entire Induction Furnace system File:Induction furnace.jpg from the Global Village Construction Set. The furnace is powered by 20 kW of 240VAC electricity from the LifeTrac generator. The entire system includes the power electronics, induction coil, and heating vessel - into which metal for melting is inserted. This diagram intends to document the relationship of functional components in the induction furnace system, as a basis for technical development of components and their integration.

The electronics part should be adaptable to different metals and different metal melting coil geometries. Melting coils should also be modular, such that the power electronics can feed different coils. Basic functions include selection of heating frequencies, which are required for melting different metals or metal geometries. There should be a feedback in the electronics, where the amount of power given to the coil should match the quantity/geometry of metal being melted.