Modular Stove Fabrication Procedure: Difference between revisions

Jump to navigation

Jump to search

(→Step 3) |

(→Step 3) |

||

| Line 34: | Line 34: | ||

==Step 3== | ==Step 3== | ||

*Plasma Cut all panels | |||

**Includes ash tray and flame deflector panels | |||

==Step 4== | |||

*Cut door and panel holders from 1/8"x1/2"x1/2" angle | |||

==Step 5== | |||

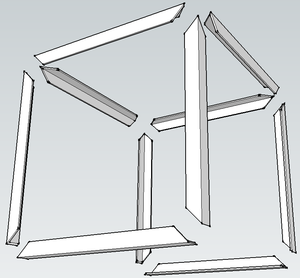

*Weld frame - all 1/4"x2" angle - as this: | *Weld frame - all 1/4"x2" angle - as this: | ||

| Line 40: | Line 48: | ||

**Mitered corners welded, ground flat | **Mitered corners welded, ground flat | ||

**Rails for flame deflector and ash tray are not mitered | **Rails for flame deflector and ash tray are not mitered | ||

==Step 6== | |||

*Weld all panel holders and door slides | |||

*Weld on holding nuts | |||

==Step 7== | |||

*Weld ash tray | |||

*Weld handles to doors | |||

==Step 8== | |||

*Plasma cut flue panel | |||

*Plasma cut flue sections, including damper section | |||

*Plasma cut flue section joints | |||

*Fabricate damper | |||

==Step 9== | |||

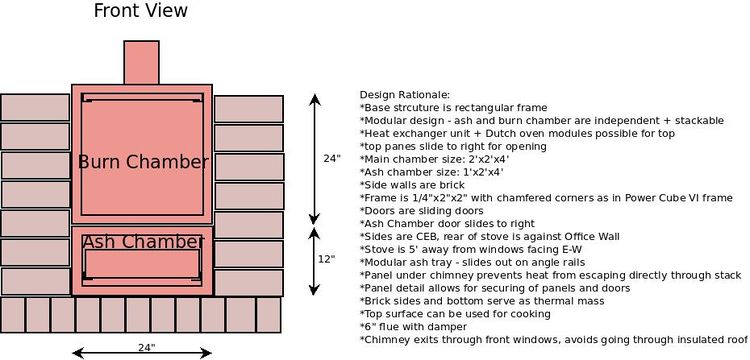

*Lay brick foundation for stove as in Concept Drawing | |||

*Stack ash chamber and burn chamber sections | |||

*Mount panels and doors | |||

*Insert flame deflector and ash tray | |||

Revision as of 01:17, 17 October 2012

BOM

Start with BOM.

- [12] - 4' long

- [18] - 2' long

- [6] - 1' long

Mild Steel

- 1/4"x2"x2" angle - $2.41/ft

- 1/8"x1/2"x1/2" angle - $0.66/ft

- 1/8"x4'x8' sheet - $100

Build

Step 1

Study Concept: 2 boxes with slideable cover plates clamped down. Ash tray and flame deflector plates side in similar fashion.

Step 2

- Cut angle for 2 mitered frames, just like for Power Cube 6. 1/4"x2"x2" angle BOM:

- Use Ironworker for mitered cuts:

- Result: corners fit together such that all metal angle form flat planes

Quality Control

- 3 corners fit so there is no more than 1/8" space anywhere

- length of members within 1/4" tolerance

Then, the build:

Step 3

- Plasma Cut all panels

- Includes ash tray and flame deflector panels

Step 4

- Cut door and panel holders from 1/8"x1/2"x1/2" angle

Step 5

- Weld frame - all 1/4"x2" angle - as this:

- Mitered corners welded, ground flat

- Rails for flame deflector and ash tray are not mitered

Step 6

- Weld all panel holders and door slides

- Weld on holding nuts

Step 7

- Weld ash tray

- Weld handles to doors

Step 8

- Plasma cut flue panel

- Plasma cut flue sections, including damper section

- Plasma cut flue section joints

- Fabricate damper

Step 9

- Lay brick foundation for stove as in Concept Drawing

- Stack ash chamber and burn chamber sections

- Mount panels and doors

- Insert flame deflector and ash tray