Torch Table Build: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 6: | Line 6: | ||

*Rack for x motion - cheapest, most robust solution for precise motion | *Rack for x motion - cheapest, most robust solution for precise motion | ||

*Spring-loaded | *Spring-loaded x and y motors | ||

=Working Concepts= | |||

==X axis== | |||

[[Image:xaxisconcept.jpg]] | |||

==Y axis== | |||

[[Image:yaxisconcept.jpg]] | |||

===Z axis== | |||

[[Image:zaxisconcept.jpg]] | |||

=Blender Concept= | =Blender Concept= | ||

| Line 18: | Line 25: | ||

**More expensive versions state they last 4 times longer - are heavier and have better temperature control | **More expensive versions state they last 4 times longer - are heavier and have better temperature control | ||

**For anything above 1 inch, torch is better | **For anything above 1 inch, torch is better | ||

=Team= | =Team= | ||

Revision as of 22:43, 21 August 2009

Proposal

See proposal at http://openfarmtech.org/Lawrence_Proposal.pdf

Design Rationale

- Rack for x motion - cheapest, most robust solution for precise motion

- Spring-loaded x and y motors

Working Concepts

X axis

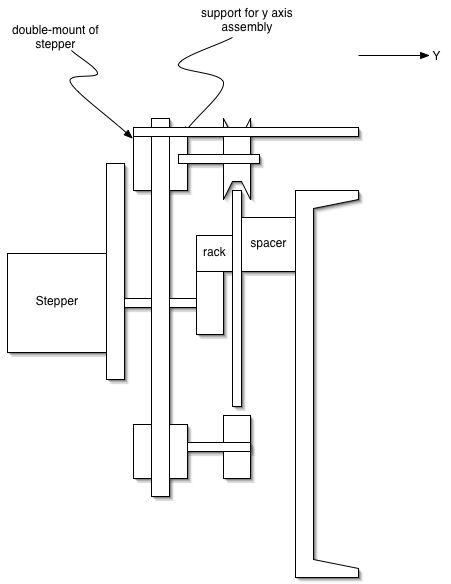

Y axis

=Z axis

Blender Concept

Torch vs. Plasma Cutter

- Comes down to initial cost versus long-term cost

- Plasma cutters - consumables cost $20 for 5 new electrodes and nozzle heads

- Electrodes are rated for 45 minutes to 60 minutes for 1/2" steel

- More expensive versions state they last 4 times longer - are heavier and have better temperature control

- For anything above 1 inch, torch is better

Team

- Deep in the continental US underground...