D3D Printer Design Process

This document lists D3D Printer Design decisions and reasoning behind them in chronological order. The intention is to make the process as debuggable as possible and facilitate later creation of formal documents such as Design Decision Tree and Conceptual Design diagrams. It follows the D3D_Design_Methodology.

Sources Driving Design Desicions in Priority Order

- D3D_Fusion_printer_design#Higher_Level_Goals

- D3D_Fusion_printer_design#Desired_Attributes

- D3D_Fusion_printer_design#Functional_Requirements

- RepRap Interface Standard

- The shape of the input determines the shape of the design and tests.[1]

Process

Concept Creation

This page was tagged as a candidate for deletion. If this page does not meet our criteria for deletion, please remove this notice.

'

Note Note: We started out this process with concept creation. This deviates from the D3D Design Methodology, but we document it here nontheless.

D3D_Printer_Design#Functional_Requirement nr 1 is that the printer should be buildable in one day, and a parallelizable build is highly desired. A random Youtube search around modularity in CNC machines led to discovering the concept of modular linear actuators, as shown by Alexander Stepanenko in a video. The concept would allow

- ... building linear actuators and other parts at the same time

- ... defining a ubiquitous standard (screw position) interface

Normally, we would reason here around advantages that the concept of modular linear actuators could provide, but OSE found its potential exciting enough to put it directly into D3D_Printer_Design#Functional_Requirements.

Instead of diving into stepwise definition of interface and linear actuator, we decided to grab the following low-hanging fruit:

- Standard Screw Interface: Nema17

- Linear Actuator: Stepper Motor + lead screw

Validation of lead screw + stepper motor

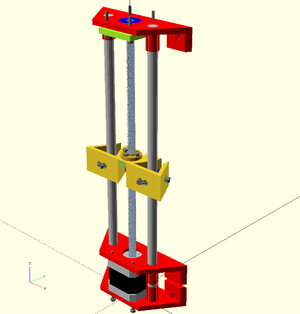

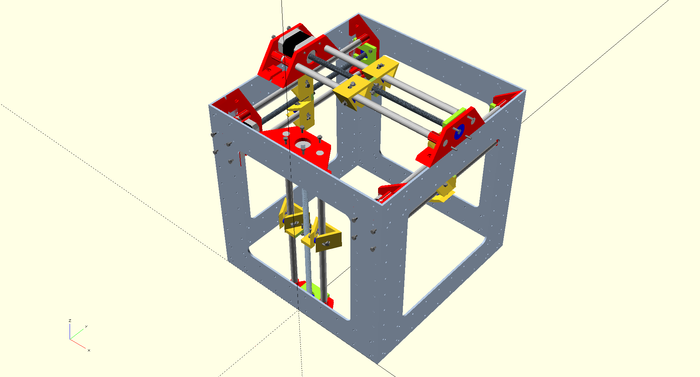

CAD viability

Looks sane...

Theoretical force viability

Finished and working 3D printers using lead screws for all axes proves this is buildable: https://www.youtube.com/watch?v=gk9lhcTGSH4

Total linear actuator weight is approximated like

| Parameter | Estimated value | Unit | Source |

|---|---|---|---|

| Motor: | 0.4 | kg | [http://www.osmtec.com/nema_17_step_motor_17_hs.htm stepper motor shop |

| Lead screw/Smooth rod: | 0.12 | kg | density=8000 kg/m^3, radius=4 mm and length=300 mm |

| Linear Bearing | 0.015 | kg | linear bearing shop |

| Hot End | 0.05 | kg | hot end shop |

| X-Carriage (extruder + hot end): | 0.67 | kg | Hotend + Motor + Four linear bearings + 0.05 kg of plastic + 20 percent |

| Linear Actuator Module: | 0.81 | kg | Motor + two smooth rods + lead screw + 0.05 kg of plastic |

| Y-Carriage (X-Carriage + linear actuator module): | 1.48 | kg | Linear Actuator Module + X-Carriage |

The linear actuator will have to meet following circa-requirements to be realistic:

| Parameter | Value | Unit | Source |

|---|---|---|---|

| Weight load: | 0.74 | kg | Y-Carriage weight/2 |

| Max Speed: | 70 | mm/2 | Requirements/choice |

| Max acceleration: | 5000 | mm/s^2 | Requirements/choice |

| Worst expected Lead screw efficiency: | 60 | % | CNC router source |

Torque from rotational inertia is not included in the table because inertia of the threaded rod is tiny (order of -7 kg m^2). Newton's second law gives maximum force needed:

F = (0.74 * 5)/0.6 = 6.16 N

3D Printer Signature

Input: Power, Build material, Supporting surface(s), Instructions Output: Physical object

3D Printer Purpose Statement

A 3D printer is a machine that synthesizes build material into 3D objects according to a series of pre-determined instructions.

3D Printer Examples

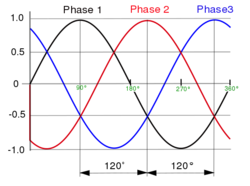

We will assume that a mains voltage will power the 3D printer, with the constant shape:

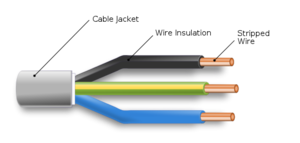

For the build material, we will assume filaments behaving roughly as thermoplastics with the constant shape: ...

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedhtdp