PVC Pipe and Fittings Library

Pipes

The dimensions of the PVC pipes can be found here PVC_Pipe. Wikipedia on Nominal Pipe Size (NPS) [1],

We will use following guide line for position of a pipe: put one end (base) of the pipe onto the x-y plane. The center of the base has coordinate (0,0,0). The other end points to the positive direction of the z-axis.

Rationale: This is the same way FreeCAD places a new cylinder. We mimic the FreeCAD behavior for UI consistancy.

The default pipe length is 1ft. This is an arbitrary choice. When I use a macro, it will store the last length used by the user.

Elbows

Useful links: [2]

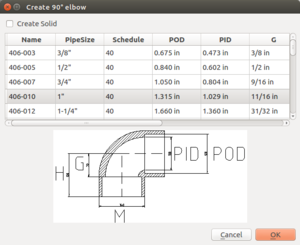

90° - elbows

Described by 3 dimensions: pipe size, schedule, G,H,M. Other dimensions are derived from NPS pipe-dimensions.

One can create 90° with alpha°-elbow macro. Just set alpha=90° and J = H. I do not know why my parameter list uses "H" for 90°-elbows and "J" for other elbows.

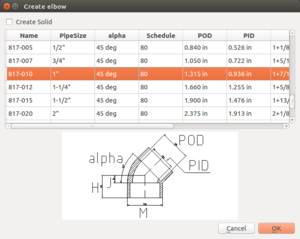

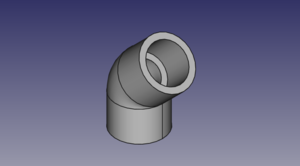

alpha° - elbows

alpha, pipe size, schedule, H,J,M. Other dimensions are derived from NPS pipe-dimensions.

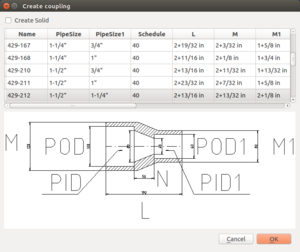

Couplings

General (Centric)

A general coupling is used to create reducer and simple couplings.

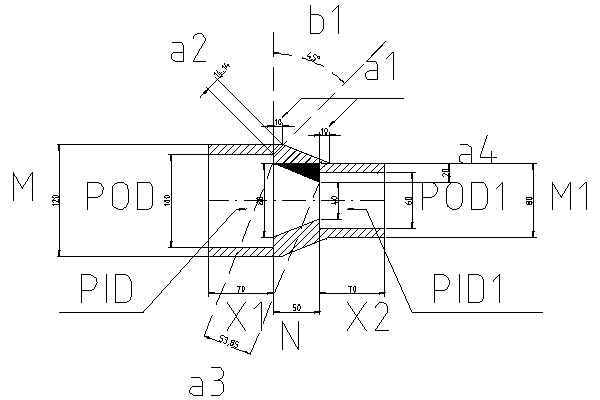

The general coupling is described by 9 dimensions: POD, PID, POD1, PID1, X1, X2, N, M, M1. The dimensions POD, PID, POD1, and PID1 are derived from the pipe sizes. The are abbreviations of Pipe Outer Diameter and Pipe Inner Diameter. The dimensions X1 and X2 are not official dimension names.

The offset a1 is calculated in such a way, that the thinest part of the middle section is not smaller that walls on of the sockets on both sides. Lengths a2, a3, a4 and angle b1 are derived from the dimensions and are only used to calculate a1.

Simple Coupling

A general coupling is described by 10 Dimensions: POD1, PID1, L, M, N. The dimensions POD1 and PID1 are not from a official specifications. They are derived from pipe size and schedule.

Reducer

The reducer coupling is described by 8 Dimensions: 4 Pipe dimensions (they follows from pipe sizes and schedule), L, M, M1, and N.

Notations

- O.D. - outer diameter.

- Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe.

- Min. Wall - thickness of the pipe wall.

- Schedule - determines (indirectly) the thickness of the wall.

Notes

"O.D." = "Average I.D."+2"Min. Wall"

Tees

Almost General Tees

Described by parameters G, G1, G2, H, H1, H2, M, M1, and pipe dimensions. As pipe dimensions we use POD, POD1, PID, PID1.

Simple Tees

Described by parameters G, G1, H, H1, L, M, and pipe dimensions. As pipe dimensions we use POD, POD.

Gallery

SCH80 1" PVC pipe - size:4kb - FreeCAD -File:Pvc-pipe-test.fcstd,

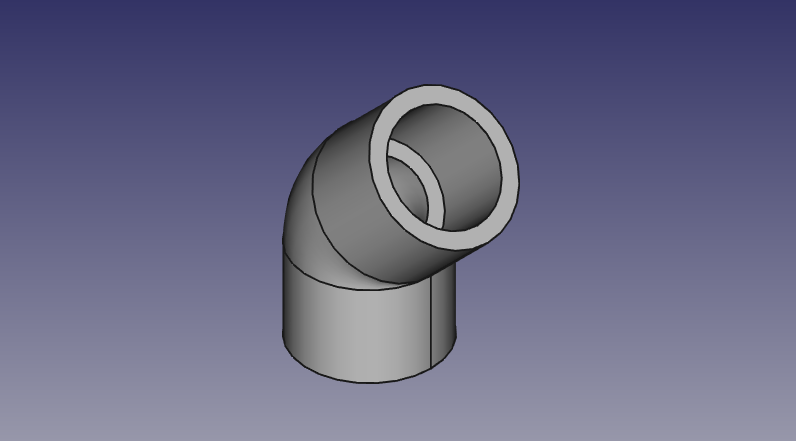

90°-elbow test file - size:17kb - FreeCAD -File:Pvc-elbow-90-test.fcstd,

Tee test file - size:24kb - FreeCAD -File:Pvc-tee-test.fcstd

Coupling test file - size:12kb - FreeCAD -File:Pvc-coupling-test.fcstd

Macros

Macros are now in a git repository [3]. The elbow macro depends now on other files. See README.md for installation instructions.

Elbows

To create an 90° elbow, run File:Create-elbow-90.FCMacro with parameters POD, PID, G, H, and M from a table. To create an elbow with an arbitrary alpha from 0° to 180°, run File:Create-elbow-alpha.FCMacro with parameter alpha, POD, PID, H, J, and M from a table.

This macro depends now on other files from [4].

Tee

Run File:Create-tee.fcmacro and select a part from the table.

Coupling

Run File:Create-coupling.fcmacro and select a part from the table.

How to create a pipe macro

Steps to create GUI: The original instruction are taken from [5] but I (Ruslan) have problems with them. I adjusted them to FreeCAD.

- Create with QT Designer a Dialog based on QDialog class. Save the name for example add-nps-pvc-pipe-dialog.ui.

- Convert add-nps-pvc-pipe-dialog.ui to python code running

- pyside-uic add-nps-pvc-pipe-dialog.ui -o pipe-dialog.py

- or call

- pyside-uic --indent=0 add-nps-pvc-pipe-dialog.ui -o pipe-dialog.py

- to use tabs as indention.

- If you use the FreeCAD macro editor, pay attention that the indention of pyside-uic and of the editor are the same.

- Insert content of the methods setupUi(self, Dialog) and retranslateUi(self, Dialog) from pipe-dialog.py (How can I insert here a block of python code?) into your macro file.

FAQ

- Do we really want to 3D-print pipe fittings? Somehow I have doubt about mechanical properties of the 3D-printed products.

- Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do.