CEB Press

This page is going to be turned into a redirect to CEB Press Intro, but first we need to strip out the useful info and put it where it's needed. Everything should end up in one of the following: CEB Press Intro, CEB Press Development, CEB Press Bill of Materials, CEB Press Build Instructions, CEB Press user's manual

Design has 5 major components:

- Documentation of CEB Prototype 1 (shown above)

- XYZ table for automating fabrication - present work, Jan-Feb 2008

- Documentation of CEB Prototype 2

- Facility Design

- Final CEB design

Social Enterprise Reviews

- Review of the social enterprise experiment by P2P Foundation

- Review by Samuel Rose of Social Synergy

- P2P Foundation review of the economic model

Economic Review

The biggest need is for a low energy stabilization method. While there are examples of buildings that have survive for many centuries, many required considerable maintenance. Others have decayed rapidly in modern times without constant recoating. One development that may make a huge difference for CEB's is enzyme stabilization. Products such as Permazyme 11X, EcoBric and others may make possible the low energy manufacture of bricks and blocks that have weather resistance approaching concrete. The enzyme products are nontoxice and relatively low cost. $40-$60 worth of Permazyme is supposed to stabilize enough earth for a large house.(1 gallon of Permazyme costs $120 and stabilizes 150 cu yds) I have been unable to find any builders using these products for CEB(though EcoBric is aimed at that market) but there seems to be considerable experience stabilizing road bases. The manufacturers have concentrated on the road building market because of the money. After all, 1 or 2 liters for a house isn't much compared to 15 gallons per mile of road. The original patents seem to have expired, so it may be possible to come up with an open-source recipe for the enzyme. It may not be an enzyme at all. The first product of this type came about when a vintner notice the the waste from wine-making hardened the soil where it was dumped.

Further Resources

- AECT - CEB press fabricator - [pages.sbcglobal.net/fwehman/]

- Powell and Sons - CEB press fabricator - [1]

- Gernot Minke - one of the world's leaders in earth construction - see [2] for thorough overview, including detailed soil testing procedures.

- Galvanized wire reinforced, earthquake resistant earth construction techniques publication - [3]

- Ronald Rael is an Architect, Author and Assistant Professor of Architecture at The University of California, Berkeley. He is the founder of EarthArchitecture.org, a clearing house of information on the subject. May be interested in our work.

- Compressed Earth Block Guide - [4]

- CEB, Manual of Production - [5]

- What can happen in earthquakes - [8] , [9] , [10]

- Other information - [11] , [12]

How about through-tie with rebar? We are considering this for double brick thickness walls. We could use technical help on this.

- Rebar can get very expensive in the developing world. The galvinized wire reinforcing is much lighter, (aka a shipping container from these guys as an examle - [13] , **probably could provide better resistance to earthquake, simular pricing to rebar per pound, and probably 5 times the support per pound of material) as well as not needing double thickness which cuts down on labor.

Bill of Materials

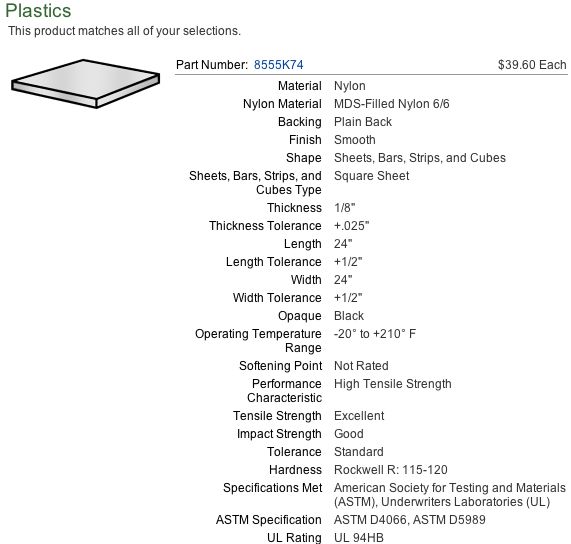

- Wear-resistant liner - MDS-Filled Nylon 6/6 from McMaster Carr

Public Responses

The following is a letter I recieved in response to a Countryside Magazine article (July/August 2008, pg 40) which discusses our building experiences at Factor E Farm. This reader has back-of-the-envelope plans for a manual CEB press. Manual presses are useful in places when labor is more accessible/cheaper than equipment. This letter also shows the general simplicity of the CEB-- the task at hand, compressing soil into bricks-- is not that complicated.