Cut CEB Metal

Jump to navigation

Jump to search

Cut 10 pieces of 7/16"x6" heavy u-channel (this link should be filled with (1) a technical drawing from a library of any professional CAD package); (2) a real picture of the material, (3) a real picture or video of someone cutting it (all of: abrasive, cold cut, band, plasma, or oxy torch)

- [4] 21" long - top and bottom of frame

- [2] 29" long - mid of frame

- [2] 10" long - compression chamber spacers

- [2] 42" long - frame sides - see Note on CEB Frame Height

- [2] 44" long - frame sides - see Note on CEB Frame Height

- [4] 6' long - arms

- [4] 4' long - legs

- [4] 6" long - 2.5"x3/16" square tubing - feet tubes

- [4] 10"x10"x1/4" flats - feet

- [2] 1/4"x2" angle, 21" long - hopper closure

- [2] 1/4"x2" angle - 7" long - hopper closure tab for cylinder alignment

- [2]

- - drawer

- - hopper

Step 1

Build frame from 6 inch heavy (7/16") u-channel

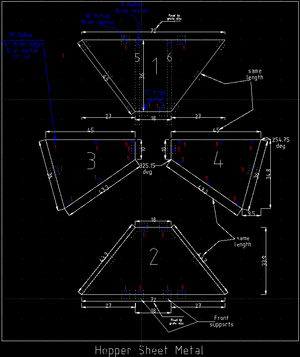

Hopper

- Plasma cut sheet metal

- Punch 3/4" holes in all 28 hinges, in center of rounded part

- Punch holes in hopper sheet metal (all the blue holes, 3/4")

- Bolt all hinges to sheet metal at the red locations marked "1" with 3/4" bolts

- Weld bottom hinges of hopper sheet 1 to hopper mount plate

- Weld top hinges of hopper sheet 1 to grate

- Install hopper supports to hold hopper sheet 1, and bolt with the 2 bolts (1/2")

- Weld hinges to hopper supports for sheet 2

- Weld hinges at base of sheets 2, 3, 4

- Weld hinges between sheets 3&1, 4&1, and between 2&3, and 2&4

- At this point, the entire hopper is erected. It remains to weld the remaining hinges to the grate.

- Upon completing these steps, the 3/4" bolts can be replaced with 1/2" bolts for successive deconstruction and reconstruction of the hopper.

- - hopper supports

- - shaker

- - hopper interface plate

- [2] 3/4" pipe, 1" long - cylinder aligner

- [2] u-channel, 3" - cylinder align