Metal Roller

| Metal Roller | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The metal roller sends sheet metal and plate through gaps between cylinders to roll-bend them; this operation is used for producing cylindrical or conical components as well as wiring cylindrical edges.

insert video embed code here

Detailed Description

The metal roller is a universal "four-in-one" machine (meaning four cylinders to work with) that performs pinch rolling operations (lightly grips and moves sheet metal through the machine with a "free" roller to "set" the required bend radius) and pyramid rolling operations (moves plate metal through the machine to "set" the required bend radius). A hydraulically power-driven universal metal roller can be used for all required roll-bending operations.

Solution Statement

The metal roller allows the operator to perform roll-bending operations with ease.

Product Ecology

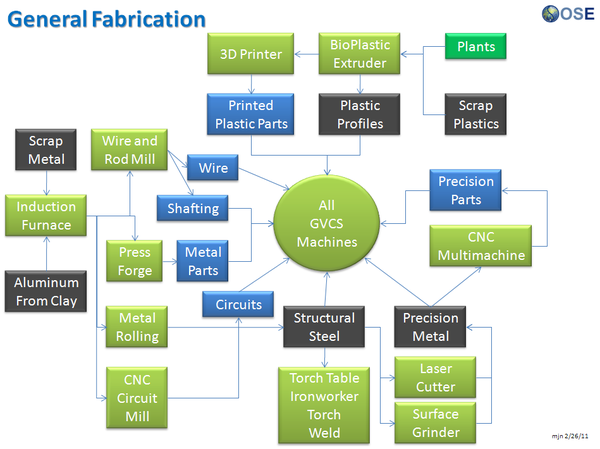

The metal roller fulfills the roll-bending role of metalworking operations in the GVCS. This ability is particularly useful for producing standard shapes of metal that would be time-consuming or impossible to form otherwise.

Components

The principal elements of the metal roller include:

- Frame: the ground-supported structure upon which the rest of the metal roller lies

- Couplers: the mechanisms that convert rotary motion from the hydraulic motor to the cylinders

- Hydraulic Circuit: the set of components that powers the hydraulic motor by sending pressurized fluid through its ports, hence producing rotary motion at the motor shaft

- Adjusters: the mechanisms that allow cylinder movement for different placement configurations on the plane perpendicular to the axis of rotation

- Cylinders: the components that make actual contact with the workpiece for roll-bending.

Specifications

| Spec | Value |

|---|---|

| Spec | Value |

OSE Project Status/Schedule

Wanted: Versioning, milestones met, future goals