September 2020 STEAM Camp

Intended Audience

People who would like to up their skills sets for building things with their hands. We focus on industrial productivity on a small scale - so all of our designs and techniques are modular and scalable. As such, what you will learn has direct applications to real-world design. For example, using the 3D printed belts and ball bearings, you can make industrial-grade geardowns for the plastic shredder.

Overview

- Remote event - with kits shipped - due to COVID

- Participation available for the world - but without kits. - kits only USA/Canada. Canada - add $70 for shipping.

- Tools are not included, need to provide some basic tools yourself

- Remote participation without kits - participate on the design lessons and classroom material, but not the builds, unless you secure parts locally or from other sources. Note that you may use Chinese suppliers (shipping time is questionable), which may work for you.

- Filament is included only for the first day sample prints. To print the rest of the projects, you'd need to get more PLA and TPU.

- 3 weekends. 4-8 hours each day, 6 days total.

- Includes OSE Linux on a USB stick - for all the software, 3D printer design workbench, frame design workbench, KiCad, FreeCAD, Arduino, Cura, and ll the software used through the program.

- Participation: each day is $25 without kits, includes OSE Linux in the USA only.

- Participation: $100 for kit for each weekend.

- Kit cost - $899. $600 for printer, $25 for OSE Linux, $60 BOM cost for electric motor + mechanics kit, $50 BOM cost for Arduino kit.

- D3D Universal 3D Printer - build from scratch

- Basic Arduino-like microcontroller - build from scratch. Parts for 2 microcontroller builds (one on a breadboard, another on stripboard) and the TV-B-Gone hacker toy as an application of the Arduino. An Arduino Uno comes with the kit. $40 alone

- 3D Printed Motor Kit - magnets, winding wire, ball bearings, metal shaft, 3-phase motor controller. Ball bearings for making large and small ball bearings. Small electric motor for geardown experiments. $70 by itself.

- Summary: $600 kit weekend 1, $150 second week, $150 third week. Or $25 kitless.

- No money? No problem. Apply for a scholarship, and we can consider providing you with free attendance in exchange for some work. Also - if you can't afford the materials cost - you can source parts at much lower cost if you make lower cost substitutions. For example, you can use smaller or weaker magnets, get a cheap 3-phase speed controller, and so forth. Different magnets will require slight geometrical modification of the design - but that's exactly what we teach you - how to do all of that in FreeCAD.

- All sales are final. Offer is limited, so reserve your seat today.

Days

- 1-2: 3d Printer Build from Scratch: learn to build a heat bed, extruder, controller, and printer - and how you can design larger versions using the Universal Axis system.

- 3: Microcontroller Build From Scratch and Programming. TV-B-Gone.

- 4: KiCad and Electronics Design: learn the basics, as you design your own Basic but Practical Microcontroller

- 5: FreeCAD - how to design like a pro. Create designs from scratch, and learn how to modify plentiful existing part libraries. Exercises: designing belts, bearings, lineaar bearings, and pulley systems. Needs 12V battery.

- 6: FreeCAD, 3D Printing, and Design. Build your own 3D Printed, 3-Phase Electric Motor Experiment from Scratch as you continue to build your FreeCAD and 3D printing skills.

Detail

The program involves 3 weekends of builds. Through the build and design sessions, we will use OSE Linux - a creative person's dream operating system - which is provided to all participants as a Live USB.

Weekend 1: 3D Printer Build. 2 8 hour days.

- Build a complete 3D printer from scratch - including a heated bed, extruder, and controller. Push the limits of what you can make yourself - and how you can start an enterprise in your community making useful parts.

- Learn to upload firmware, calibrate the first print - and begin printing.

- Build a 3D Printer Extruder from Scratch. Learn how an extruder works, and how you can redesign it yourself.

- Design Lesson on Making industrial-grade extruders with 80W heaters for 20 lb/extrusion rates

- Build a heated bed from scratch. The same technology of nichrome heaters can be used for kilns and furnaces to melt aluminum.

Hours:

- Hour 1: 11 AM to Noon: 30 minute OSE Intro - Collaborative Design, This is a real exercise in collaborative design.

- Hour 2: Noon. Extruder Build Beginning - 15 minutes - design of an Extruder and how to design a different one. We all post pictures to a Google Photos Folder or FB, and documenters refine the documentation

- Hour 3: Heat Bed Build - Build Nichrome heater element, and make a heated bed with it. Includes 15 minutes on heater element design and nichrome wire calculations so you can redesign a heater element of any size.

- Hour 4: Universal Axes build - Includes 15 minutes on Universal Axis design - and how to scale these to any size frame.

- Hour 5-7: finish extruder, axes, heat bed.

- Hour 8: Build review: we discuss build and any trouble spots to make improvements.

- After hours and before next day's 11 AM start: participants finish any unfinished parts.

Day 2:

- Hour 1-2: 11 AM to 1PM: Controller build. 15 minute lesson on the Universal Controller.

- Hour 3-5: Startup procedure. 1. Check direction of motors, including extruder. First prints.

- Hour 6: Using FreeCAD to Create Designs for 3D printing.

- Hour 7: Your first simple design - sliced and 3D printed.

- Hour 8: How would you make or 3D print all the 3D printer parts yourself? Or use the 3D printer to make a torch table to make tractors? This is all possible, and we'll teach you how. Our goal is to make more parts of the 3D printer: bearings, shafts, controller, screen, relay, plug, and more. Discussion on the technology required to make each, based on what is found in the Global Village Contruction Set. Last 20 minutes: Lessons learned - how to make the program better.

Weekend 2: Arduino, KiCad, Programming, and Building a working Microcontroller From Scratch

This weekend, you will learn how to make functional, programmable microcontrollers - from a chip that you can buy for one dollar. You will learn basics of coding and controls, as you build 2 working miccrocontrollers - one on an experimental breadboard, and another on a soldered circuit board.

Day 3, 4 hours:

- Learn Arduino, coding, and build your own Arduino-like microcontroller from scratch. With Mitch Altman. See details at Arduino for Total Newbies.

Day 4, 4-5 hours: Learn KiCad and basic electronics design as you design and build your own microcontroller. Experience the full chain from KiCad to a working microcontroller that you solder on a stripboard to make a functional device that can be programmed and used in practical projects.

- Hour 1-2: KiCad intro: 15 minutes. Begin designing your own microcontroller: selecting components, making connections, and checking your design. Exporting a layout that you can work from to solder your own OSEno - the minimalist OSE Arduino clone - on a stripboard.

- Hour 3-4: Soldering, making and breaking connections, and populating circuit board with components.

- Hour 5: KiCad review - making a change in the circuit. Testing - making LEDs blink, and turning on heavy loads with a solid state relay. Note: we will be using the existing solide state relay from the D3D Universal - so if you haven't built the kit - you'd have to get your own solid state relay to do the experiment first hand - otherwise you can watch others do it. Also wrapup: discussion on learnings, and how to improve the program.

Resources

- Art of Stripboard and KiCad - [1]

Weekend 3: FreeCAD Design + Build Your Own 3D Printed, 3 Phase Motor

Day 5, 4 hours lessons + 4 hours practice: Learn more about FreeCAD design as you design and modify ball bearings, linear bearings, transmission belts, and pulleys - all that you can print with your 3D printer to make various kinds of transmission and power geardown systems. You will be provided with bearing balls - large and small - to build your projects. We want you to think about a low-cost, high force geardown that can be build for a plastic shredder for plastic recycling for 3D printing.

- Hour 1: The Ball Bearing. FreeCAD - using spreadsheets and modifying a 3D printable ball bearings. Then 3D print your ball bearing.

- Hour 2: The Linear Bearing. Learn how to design, modify, and print a linear bearing - either will bearing balls or with plain plastic on metal.

- Hour 3: The flexible belt. Learn how to design, modify, and print rubber belts.

- Hour 4: The Pulley. Design, modify, and print pulleys for power transmission.

- Hour 5-7: Exercises. Collaborate and design a geardown. Use the small provided 100W motor, bearings, shafts, pulleys, and belts to build interesting examples of functional beleted drive drains. See inspiration at Open Source Shredder Build Pictures and Video

- Hour 8: Show-and-Tell - show the class what you have built, and how it works. Discussion and lessons learned.

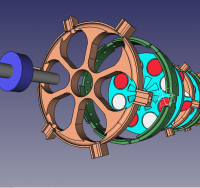

Day 6, 8 hours: Now you can use your FreeCAD skills and 3D printer to design and build a 3D printed, 3-phase, electric motor: Dirk's Electric Motor. This is an experimental day where you can take our existing design - and build it to get first-hand knowledge of how to design and build an efficient, brushless electric motor - whose power can be stacked by adding more disks to the system. To do this - you will have to have printed all the parts prior to this day - as it takes a day to print all the parts.

- Hour 1: The OSE 3 Phase Motor Design. How to scale it to larger sizes or add more disks to it. Power, magnetic field, and speed calculations. Brushed vs brushless motors. Axial vs radial(45 minutes).

- Hour 2-3: Start with winding the windings. You will need a corless drill so you can grab the windings to wind them quickly.

- Hour 4: Attaching the magnets to the rotor, coils to stator, and connecting to 3-phase motor controller.

- Hour 5-7: Finishing the build. Participants work toward completion, and ask questions along the way.

- Hour 8: First run! Discussion: applications and possible applications of motor. Lessons learned, discussion, and feeback on future improvements.

Bills of Materials

First Weekend

- D3D Universal kit - [2]

Second Weekend

- Arduino Uno -

- Breadboard -

- Strip Board -

- Components -

- Solder

- Soldering Iron

3rd Weekend

- Dirk 3D Printed Electric Motor BOM

- Bearings, bushings, and geardowns BOM

- Small electric motor - Jameco Electric Motors, but shipping is expensive outside of minimum order.

Sat-Sun Oct 3-4, 2020 - FreeCAD and 3D Printing an Electric Motor

- FreeCAD design - Gaining basic proficiency in designing anythign you dream of. Working with Dirk's Electric Motor and printing it.

- Electric Motor Design. 3D printing an electic motor - before this weekend so parts are ready and we build it. FreeCAD design exercises - modifying the electric motor. FreeCAD spreadsheets for parametric design.