September 2020 STEAM Camp Curriculum

The program involves 3 weekends of builds. Through the build and design sessions, we will use OSE Linux - a creative person's dream operating system - which is provided to all participants as a Live USB.

Weekend 1: 3D Printer Build. 2 8 hour days.

- Build a complete 3D printer from scratch - including a heated bed, extruder, and controller. Push the limits of what you can make yourself - and how you can start an enterprise in your community making useful parts.

- Learn to upload firmware, calibrate the first print - and begin printing.

- Build a 3D Printer Extruder from Scratch. Learn how an extruder works, and how you can redesign it yourself.

- Design Lesson on Making industrial-grade extruders with 80W heaters for 20 lb/extrusion rates

- Build a heated bed from scratch. The same technology of nichrome heaters can be used for kilns and furnaces to melt aluminum.

Hours:

- Hour 1: 11 AM to Noon: 30 minute OSE Intro - Collaborative Design, This is a real exercise in collaborative design.

- Hour 2: Noon. Extruder Build Beginning - 15 minutes - design of an Extruder and how to design a different one. We all post pictures to a Google Photos Folder or FB, and documenters refine the documentation

- Hour 3: Heat Bed Build - Build Nichrome heater element, and make a heated bed with it. Includes 15 minutes on heater element design and nichrome wire calculations so you can redesign a heater element of any size.

- Hour 4: Universal Axes build - Includes 15 minutes on Universal Axis design - and how to scale these to any size frame.

- Hour 5-7: finish extruder, axes, heat bed.

- Hour 8: Build review: we discuss build and any trouble spots to make improvements.

- After hours and before next day's 11 AM start: participants finish any unfinished parts.

Day 2:

- Hour 1-2: 11 AM to 1PM: Controller build. 15 minute lesson on the Universal Controller.

- Hour 3-5: Startup procedure. 1. Check direction of motors, including extruder. First prints.

- Hour 6: Using FreeCAD to Create Designs for 3D printing.

- Hour 7: Your first simple design - sliced and 3D printed.

- Hour 8: How would you make or 3D print all the 3D printer parts yourself? Or use the 3D printer to make a torch table to make tractors? This is all possible, and we'll teach you how. Our goal is to make more parts of the 3D printer: bearings, shafts, controller, screen, relay, plug, and more. Discussion on the technology required to make each, based on what is found in the Global Village Contruction Set. Last 20 minutes: Lessons learned - how to make the program better.

Weekend 2: Arduino, KiCad, Programming, and Building a working Microcontroller From Scratch

This weekend, you will learn how to make functional, programmable microcontrollers - from a chip that you can buy for one dollar. You will learn basics of coding and controls, as you build 2 working miccrocontrollers - one on an experimental breadboard, and another on a soldered circuit board.

Day 3, 4 hours:

- Learn Arduino, coding, and build your own Arduino-like microcontroller from scratch. With Mitch Altman. See details at Arduino for Total Newbies.

Day 4, 4-5 hours: Learn KiCad and basic electronics design as you design and build your own microcontroller. Experience the full chain from KiCad to a working microcontroller that you solder on a stripboard to make a functional device that can be programmed and used in practical projects.

- Hour 1-2: KiCad intro: 15 minutes. Begin designing your own microcontroller: selecting components, making connections, and checking your design. Exporting a layout that you can work from to solder your own OSEno - the minimalist OSE Arduino clone - on a stripboard.

- Hour 3-4: Soldering, making and breaking connections, and populating circuit board with components.

- Hour 5: KiCad review - making a change in the circuit. Testing - making LEDs blink, and turning on heavy loads with a solid state relay. Note: we will be using the existing solide state relay from the D3D Universal - so if you haven't built the kit - you'd have to get your own solid state relay to do the experiment first hand - otherwise you can watch others do it. Also wrapup: discussion on learnings, and how to improve the program.

Resources

- Art of Stripboard and KiCad - [1]

Weekend 3: FreeCAD Design + Build Your Own 3D Printed, 3 Phase Motor

Day 5, 4 hours lessons + 4 hours practice: Learn more about FreeCAD design as you design and modify ball bearings, linear bearings, transmission belts, and pulleys - all that you can print with your 3D printer to make various kinds of transmission and power geardown systems. You will be provided with bearing balls - large and small - to build your projects. We want you to think about a low-cost, high force geardown that can be build for a plastic shredder for plastic recycling for 3D printing.

- Hour 1: The Ball Bearing. FreeCAD - using spreadsheets and modifying a 3D printable ball bearings. Then 3D print your ball bearing.

- Hour 2: The Linear Bearing. Learn how to design, modify, and print a linear bearing - either will bearing balls or with plain plastic on metal.

- Hour 3: The flexible belt. Learn how to design, modify, and print rubber belts.

- Hour 4: The Pulley. Design, modify, and print pulleys for power transmission.

- Hour 5-7: Exercises. Collaborate and design a geardown. Use the small provided 100W motor, bearings, shafts, pulleys, and belts to build interesting examples of functional beleted drive drains. See inspiration at Open Source Shredder Build Pictures and Video

- Hour 8: Show-and-Tell - show the class what you have built, and how it works. Discussion and lessons learned.

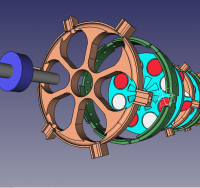

Day 6, 8 hours: Now you can use your FreeCAD skills and 3D printer to design and build a 3D printed, 3-phase, electric motor: Dirk's Electric Motor. This is an experimental day where you can take our existing design - and build it to get first-hand knowledge of how to design and build an efficient, brushless electric motor - whose power can be stacked by adding more disks to the system. To do this - you will have to have printed all the parts prior to this day - as it takes a day to print all the parts.

- Hour 1: The OSE 3 Phase Motor Design. How to scale it to larger sizes or add more disks to it. Power, magnetic field, and speed calculations. Brushed vs brushless motors. Axial vs radial(45 minutes).

- Hour 2-3: Start with winding the windings. You will need a corless drill so you can grab the windings to wind them quickly.

- Hour 4: Attaching the magnets to the rotor, coils to stator, and connecting to 3-phase motor controller.

- Hour 5-7: Finishing the build. Participants work toward completion, and ask questions along the way.

- Hour 8: First run! Discussion: applications and possible applications of motor. Lessons learned, discussion, and feeback on future improvements.