Truss Design

Jump to navigation

Jump to search

Day 3

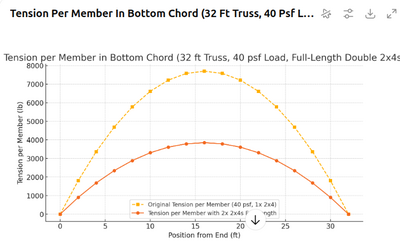

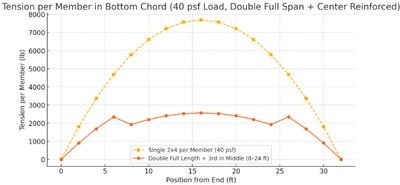

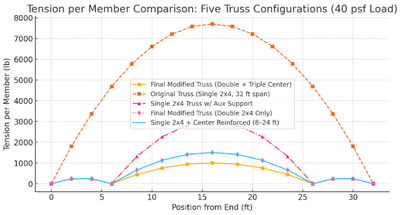

- Look at what happens to the tension at the bottom chord with 1 and 2 reinforcements of 2x4x16' in the middle. Middle section is completely reduced in tension on bottom chord - but where the chord ends is still problematic. [1]

- First, reduce from 50 to 40 psf load. [2]

- Let's do a double 2x4 bottom. It works - now we are down to about 4000 lb tension per member [3]. Can the 2 2x4s support the tension?

- For each chord, there should be 40 staples to hold 4000 lb of tension in the chord to make a good connection to the OSB. [4]

- For a double 2x4, this is the tension held per each 2x4 of the bottom chord - [5]. This is near the bottom chord tension capacity per 2x4 of 3000 lb force:

- Add a reinforcing 2x4x16' at the bottom, and we are at 2600 lb tension per member. [6]

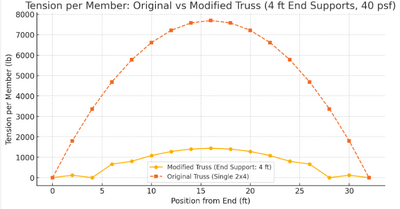

- Protrude more trusses from side to support an extra 6' from each side: [7]

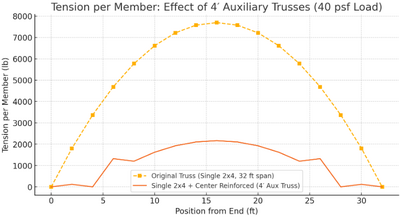

- Auxilary support to 6 feet, with a single 2x4x16' in the middle - suffices completely for 40 psf load on a 32' truss! Effective span is 20' outside of the doubling. [8]. The trick is the 6' auxiliary support - it actually outperforms the doubling of the truss (12" oc instead of 24"oc) at the cost of only 12' as opposed to 32' of material? Incredible!

- Critical insight - use auxiliary trusses to effectively reduce span, and address the main challenge - that the bending moment goes as the square of the truss length! Reducing the effective span is key to using less material. This outperforms using double the number of trusses! Now the only question is, what requirements must the auxiliary trusses meet to provide effective span reduction? They must be strong enough to support weight of main truss.

- Critical insight - use auxiliary trusses to effectively reduce span, and address the main challenge - that the bending moment goes as the square of the truss length! Reducing the effective span is key to using less material. This outperforms using double the number of trusses! Now the only question is, what requirements must the auxiliary trusses meet to provide effective span reduction? They must be strong enough to support weight of main truss.- It doesn't appear to matter if main truss does not sit on top of wall - the aux truss seems capable of holding the extra weight (shear force on aux truss is 2400 lb max, for total load capacity of 4800 per truss and we have 3200 design weight at 50 psf. [9]. Yes on shear [10].

- For supporting 3200 lb, or 1600lb each side - need either 22 nails or 50 16 ga staples, or both in compo. Nails probably last longer. Use 3" nails, 2.5" min (2 webs + chord). [11]

- Now redo for 4' aux truss [12]:

Day 2

- Tensile strength of SPF - 300 psi, even though 10000 is for perfect wood. National Design Specification states 500 psi for tensile SPF, p11 for 2x4. 2x6 is lower. [13]. But that seems to be for #1 lumber, not #2. 500 seems to be right - considering snow load - [14]. Look at Table 4A - SPF - [15]

- Compressive PSI of SPF #2 is over 2x the tensile strenght of SPF #2 [16]

- Snow load is not added to the oerall roof design load (because it is included in love load) unless snow load dominates (>20 psf) [17]. Note that wind, rain, snow are not included in live loads. Live loads are only maintentance and people.

- Detailed dead load - 3/4" OSB (2.5 lb), 1" wet gravel (11 psf [18], solar panels (50 lb [19] over 20 feet, or 2.5 psf), 30 mil RPE (0.1 lb), for 32' long truss it is 6 lb/ft [20]. Total dead load 22 psf. With 3/4" of pea gravel, we have 20 psf dead load. But you want to use 1.5", or 13 psf [21]. Expanded clay shaves off 10 psf from this (10x lighter than pea gravel). [22]. Pumice is 7x lighter, but 4x more expensive ($1/sf vs $0.25/sf). Aircrete Balls are the clear answer. [23]

- Dead load - 12 psf reduction allowed if snow load <20 psf. [24]

- In any case, Factor e Farm is 40 psf as above for full code compliance.

Day 1 - 32' Long Trusses with 1/2"x16" OSB Web and 2x4 Chords

- For a 32' long truss with 1/2" web, the limiting factor for span is not the web - it's the chords. In fact, there could be a break in the OSB in the middle, and it would not affect the truss bearing capacity much - but a break near the support points would be catastrophic. [25]

- 32' truss with 24" on center - 1/2" web by 16" tall - has 3200 lb on it at 50 psf, and 1600 shear at ends. Shear capacity of the OSB is 2400 lb, so we are fine on shear. [26]. We are not fine on tension at bottom chord [27]

Solution: use half inch rebar, 20' long, stapled to the bottom of the bottom 2x4 chord of the truss. 100+ staples with the rebar holds a total of 12000 lb of tension - exceeding the tension requirement of a 32' joist bottom chord - for rated design of 50 psf total roof load. Yes, nice, but there is no easy way to attach the rebar to the wood. Simpson strips would do, but they are like $2/foot for what we need, so doubling up 2x4 is 1/4 the cost of <10 lb extra weight.

Solution: use half inch rebar, 20' long, stapled to the bottom of the bottom 2x4 chord of the truss. 100+ staples with the rebar holds a total of 12000 lb of tension - exceeding the tension requirement of a 32' joist bottom chord - for rated design of 50 psf total roof load. Yes, nice, but there is no easy way to attach the rebar to the wood. Simpson strips would do, but they are like $2/foot for what we need, so doubling up 2x4 is 1/4 the cost of <10 lb extra weight.- More: shear at 6' from end - at terminus of 20' mid-reinforcing rebar - is 1600 lb for 50 psf total load specification - and tensile requirement for bottom chord is 3600 lb. Quality controlled 2x4 lumber has a tensile strength of 600 psi (12 ksi for ideal)

- Big point: ideal SPF wood is 10 ksi tensile - 30x more than its 300 psi 'design rating' for tensile strength. So as long as we inspect visually for quality, we can expect 1000 psi tensile strength for a visually inspected, defect-free specimen. Thus, we can use a single 20' rebar in the middle of 30' truss - and be fine for the required 3600 lb tension at the 6' point where the 20' stick or rebar ends - if we rely on the bottom chord of 2x4 lumber to hold the remaining tension [28]