OSE Shop 2011

Main > Housing and construction

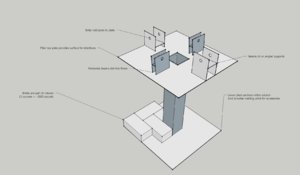

A 12 cell (16'x16') workshop for prototyping and production runs of open source ecology machines

See also the prototypical CEB Living Unit

Design Model

Youtube quick Tour here [http://www.youtube.com/watch?v=gsowoMjSy2I]

Sketchup model: [http://sketchup.google.com/3dwarehouse/details?mid=461634956aef7a94d79276599ab9c72d]

Embed:

Notes for model update

- create tie detail for roof beams to roof boxes

- create rebar plan

- show possible insulated infill plan

- show possible uninsulated infill plan (shed may do)

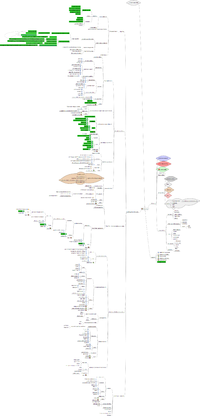

Construction Plan Mindmap

Full size here:[[1]]

Actual Mindmap file here (created with freemind) [[2]]

Supply sources

Sand & Gravel - Larry McFee - Maysville - 816 724-0736

Alternate Proposals

Youtube tour showing alternate: [http://www.youtube.com/watch?v=g-hbmR_u4x4]

Sketchup model: [http://sketchup.google.com/3dwarehouse/details?mid=e9d1adaf725fff85d79276599ab9c72d]

Embed:

Equipment Room

Add an equipment room on the storage shed.

This will keeps the noise of the compressor, generator, hydraulic pump, and such away from the shop. Will also provide storage for smaller parts.

Rotate Building

- Presents the gantry as an 'entrance arch' to Factor-E Farm

- Moves the storage shed closer to the existing shop

- allows more southern exposure for the clerestory in winter

- Changes drainage plan

- makes cistern overflows more logical (into ditches)

- Moves the storage shed out of the land where cordwood hut is now

Expand Shop

- Simply move last row of columns out 7.5 feet

- Very moderate cost for 500 additional square feet of space

Use 2x6

2x6's cost *half* of what 2x10's cost. We're spending almost $3000 on lumber. Can we save $1500?

This calculator externally:

Indicates that 2x6's can be used for our spans easily if our snow load is less than 10 pounds per square foot (about a foot of snow), and probably are even okay for 10 pounds per square foot.

It is my judgement that at least shifting to 2x8's to save cost would be worthwhile. 2 x 6's will work fine, the vast majority of structures use them.

Cost Estimates

Also see Factor_e_Farm_Infrastructure_Buildout_2011

Design feedback from a Production/Floor designer

Outline extracted from a conversation between David Ihnen (design proposer) and David Dalton of Kansas City, a professional production floor layout contact.

- Shop Design:

- likes the roof angles

- Chlerestory brings lots of light in, that is good

- Gantry is good

- Biggest problem: Headspace.

- low cieling feels claustrophobic, is not so nice to work in.

- extra cieling space can be used to hang racks and store materials

- too little overhead space and you can't do anything about it

- Gantry system needs space for hoist - it would lucky to be able to lift a lifetrac off the ground at its current height of 9 feet at top.

- Storage space

- A nearby building - suggest the gantry extends to a shed to the north, where production materials will be stored. Gantry allows easy retrieval without ground level improvements (concrete).

- Compressed Air.

- Compressed air is critically important for cleanup, blowing bits out of crevasses better than about anything.

- Compressed air tools are bulletproof - electric ones wear out quickly,compressed air tools do not.

- Compressed air tools are powerful and buffered - no matter how slowly compression is generated, maximal power is available at the moment it is needed.

- Compressed air does not require electricity - either directly off of wind power (good idea!) or steam, or gas engine, or lister - whatever.

- Take the time to distribute your compressed air around the shop

- keep your requirement for flexi-hoses short, 4 inner columns good location for them

- Gantry.

- Excellent materials handling solution

- makes moving heavy things, lifting them up, etc far easier - when dealing with heavy things, that hoist can make a world of difference.

- Transport from storage to production floor is easy and smooth

- Tiger Stop

- All About Tigerstops: [[4]]

- Example used model on ebay [[5]] - sold for $4500

- Any sort of production needs a length-measuring table with adustable stops for efficiency

- tiger stop style table will accelerate production massively - 30-40% easily.

- fully automatic tiger stop style table will accelerate parts cutting even more

- is a single-axis cnc - not difficult to arduino and construct ourselves!

- consider a double ended table, one end bandsaw, one end mitre saw

- HIGH USE TOOL - as the most frequently useful tools in the shop, it should be centrally located

- Can also be equipped with a drill press for automating positioning of materials to be drilled!

- The Robots.

- Put robots in range of equipment

- consider flexibility - hard-mounted robot gets in the way when not being used

- robots are useful only when actively programmed.

- board mill->robot->rack->robot->cnc->robot->rack workflow could automatically create wooden parts

- robot combined with tiger stop type table could automate much workflow of creating metal parts too

- Table Saw

- You ABSOLUTELY DO want a table saw if you're doing wood fabrication

- a large one - or don't bother

- can double as workbench with blade retracted

- Dust Collection

- Install a dust collection system if you're going to be routing and/or cutting much wood. Recycle the chips for fuel, and the fine sawdust is even more useful.

- use a two stage filtration chamber to separate - easy to build

- Curtains

- Put BLACK curtains around the welding areas.

- Welding flash causes eye damage, even indirectly

- Welding exposure is bright UV, impacts more than merely the eyes of those around, radiation burns too.

Materials and Budget

- 4 Milwaukee cordless drills - $407

- Roof metal - 136 panels, 17' long (3' widths) - 108 for workshop, 22 for material shed, and 6 extra + flashing for clerestory + screws + flashing closure - total $5871

- 2x6 lumber, $6.60 - total 396 pieces - total $2802

- Glue, #25 star driver bits, 3" star bit screws, 2 glue guns, furring strips, 2 tie downs - $299

- Trailer rental for lumber - $47

Technical Notes

Roof Tie

The use of Simpson Strong Tie model 2.5 can bind the roof panels to the rafter boards in such a way as to bind the roof to the rafters. We will use 100 of them, tying all of the edges and middles of the roof boxes to the rafters.

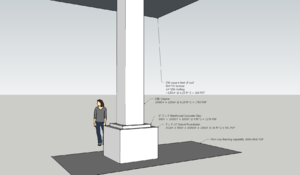

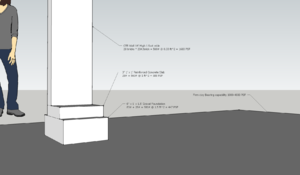

Foundations

The site is a heavy clay soil with a calculated bearing capability of between 1000 and 4000 pounds per square foot. The foundation design goal is to bring the building static load below 1000 PSF, so that the possible live load (gantry crane loaded, snow on the roof) even doubling the load will keep the foundation pressure beneath 2000 PSF.

Work documentation

How to make a water level: http://www.youtube.com/watch?v=nAcT_1T25LM

How to lay a brick: http://www.youtube.com/watch?v=lORIZ1shRIM