Torch Table Motors

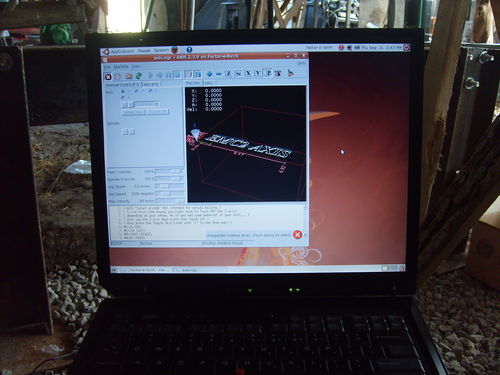

Overview

CNC Torch Table Motor design/issues.

CNC Torch Table Motor design/issues.

Xylotex

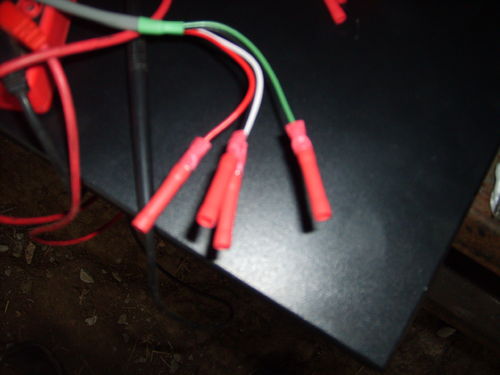

One of the channels has gone bad unfortunately and the most likely cause is that there was a loose connection which caused an intermittent short. From the documentation, it is strongly suggested to not unplug the motors while the controller is on. One reason for this is that stepper motors act like large inductors, and when an inductor is discharged they can produce high voltage spikes. Now, a loose connection can act an awful lot like unplugging the motor while turned on. All the wires were tightened down hard which should alleviate the cause but the problem still needs fixing.

From Jeff at Xylotex

Hi, The part number is A3977SEDT from Allegro Micro. These are available from www.digikey.com

The glue holding the heatisk on is thermal adhesive, to conduct heat to the sink from the chip. If you pry between the chip and heatsink, you should be able to pop it off. Do not pry between the board and the heatsink, as this could possibly rip the chip off the drive board, taking traces with it and wrecking the board.

Once the heatsink is off you can use a hot air gun to melt the solder and remove the chip. Be sure to protect the other devices on the drive board from the hot air. Or, if you are careful, you can cut all of the leads and then clean up the pads. Again be careful so as not to rip up pads and traces.

Digikey has the part for under $9 dollars, which makes this the cheapest and probably the easiest fix.

The next option is to replace the channel with a stand alone modular stepper motor controller board. RepRap has them and MakerBot Industries sells them for $20. On top of that you'll have to figure a way to wire it into the appropriate parallel port pins, which is an exercise left for the student to complete. (hint: look at the plasma controller interface)