XYZ Table

Main > Digital Fabrication > RepLab Tools > Torch Table

Overview

Development work for the  CNC Torch Table

CNC Torch Table

Concept

- Open Source Stepper Motor Controller

- Self-replication concept - metal for torch table can be cut on torch table itself, minus precision drive. Precision drive produced on Multimachine

- Retrofittability with larger motors and stiffer tubing for use as a router table

- Retrofittability with acme or other screw mechanism - this would be rather readily done with the existing system

- Bolt-together design for simplicity and flexibility of adapting this design to other uses (CNC Circuit Mill, other xyz motion comparable to CubeSpawn

- Gear rack mechanism for low cost of drive.

Specifications

Specifications: Eventual Deployment

- Toolpath speed: up to 1 inch/second

- Interchangeability of heads

- Torch

- Router

- Laser cutter

- Plasma cutter

- Scaleability of main axis drive

- Piggybacking of stepper motors

- Controller scaleability from 3 to 6 motors

- Guides are precise up to .0004"

- Screw motion is adaptable via screw interchangeability and gear addition

- Precision to .01" for torch table

- Precision to .0004" for circuit fab and lathe work

- Gears may be added for lathe work

- Adaptability to high precision (.0004") at $300 increment

- Table structure rests on blocks to minimize frame requirements

Specifications: Motors

- Up to 18 motor-amps

- Max RPM of motor -

- Steps

Precision

- Rail tolerance:

- Screw backlash:

- Screw threads per inch:

Specifications: Controller

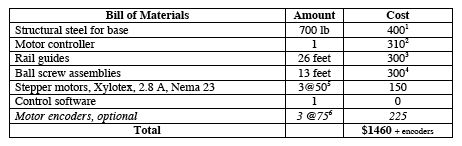

XYZ Table Bill of Materials

The bill of materials for the XYZ table shown here is:

XYZ

Main > Digital Fabrication > RepLab Tools > Torch Table

XYZ Table Development Log

Here is a log of XYZ table development. The background: build an XYZ torch table for producing the metal components of a CEB Machine. See here for CEB machine fabrication.

CAD_CAM_EDM_DRO Yahoo Group

- This groups provided the most useful advice: it addressed the questions asked specifically.

Answer 1

Belt works well on plasma cutters. Screws are usually too fine as you need speed more than resolution.

The holding torque figure for a stepper isn't actually very helpful. As soon as you start moving the motor, the torque falls off. As a rough rule of thumb you can only use about 1/4 of the motor's holding torque. Your 425 oz-in motors will effectively produce only about 100 oz-in. With a 2" diameter pulley you will have a maximum force of 100oz (torque/radius). As you have two motors you will have a linear thrust of about 200 oz or 12 lbs. At a guess you will probably lose getting on for half of that in friction, giving you about 6 lbs useful force. For accurate cutting you need good acceleration. I would think 0.5g would be a minimum to aim for. Therefore your gantry can't weigh more than 12 lbs total. That is pretty light. The good news is that you will have a very high top speed, assuming you have enough acceleration to get there.

If you use a 1" diameter pulley the numbers look a lot better. The thrust per motor now becomes 100/0.5 = 200oz. As you are using two, that becomes 400 oz total, or 25 lbs. You still lose about 6 lbs in friction, leaving 18lbs to accelerate your gantry. The gantry can now weigh 36 lbs. Assuming a maximum reliable speed of 1500rpm from the motor you will have a top speed of 750IPM. That is pretty damn quick.

I wouldn't recommend using the belting flat . You will probably find that the pulley engagement is not smooth and you will get slightly rough motion. A far better method is to use two idlers to wrap the belt around the pulley. Think of the Greek letter omega. I'll try for some ascii art but it may not come out very well: O | | __O O___

The idlers can be made out of a cheap skate bearings. Skate bearings are 8mm wide so two side by side will be wider than the belt. 3/8" pitch seems quite coarse to me. On the next page in the McMaster Carr catalogue they have some 1/2" wide XL belting. That would also allow you to use a smaller pulley.

Les

Answer 2

Marcin:

If I were to make a 4 x 8' oxyfuel machine which needs to run at 30 IPM (MAX !!), I'd make a single side drive for the 8' axis and use a delta shaped frame requiring the main rail be maybe 3' longer on the driven side. Thus you will need TWO steppers for your drives, and you can use (2) Gecko Systems 10x microstepping amps.

Use rack and pinion drive for both axes. Rack can be gotten from Standard Steel Specialties, stdsteel.com/gear.htm at a cost of around $23 for each piece if 1/2 x 1/2 x 6 feet length in quantities of (2) pcs. They stock 20 DP, 20 degree pressure angle rack. I would ask if they could supply 24 DP, 20 degree rack as we used to buy these from then in quantity.

Since the drive pinions need to have at least 18 teeth in order to have no undercutting, these are the smallest pinions you should use if you wanted direct drive. If you were to use 24DP, 18 tooth pinions with 10X microstepping, you would have a resolution of .0011781 inches per microstep.

As to the available force from this setup, I must respectfully disagree with Les Newell regarding the torque/force available at low speeds. Looking at the Pacific Scientific spec sheet for NEMA 34 frame single stack N31 motors with microstepping (.707 x torque) gives about 315 ounce inches at this very slow speed. With an 18 tooth pinion, radius = .375 resulting in 840 Oz force or 52# force.

While I might practically opt for some sort of belt reduction between the stepper and the pinion so as to use a larger diameter drive pinion, the numbers above are still quite realistic.

To summarize, 1) Use rack and pinion drives 2) Drive the relatively narrow side (4 ft. wide machine) from one side; design the main carriage and main rail to do this. 3) You can use direct drive with a resolution per step of .0012 per step

I have pictures and data from my small test bed machine. You can reach me at jccinc-at-owc-dot-net.

Regards, Jack C.

2 Continued

Marcin,

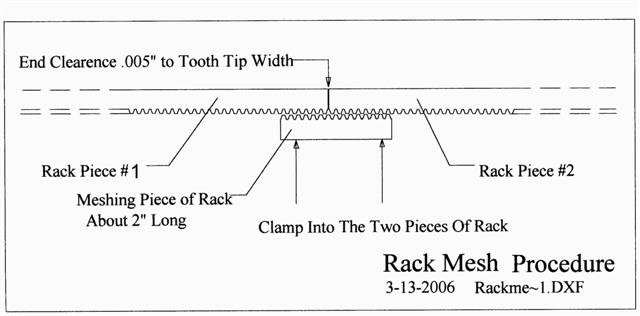

If gear rack comes in 6 foot sections, here is a joining procedure:

Use metal rack and pinion for durability, as opposed to rubber (neoprene) belts.

>>You can get pinions from Boston Gear and Martin Sprocket and Gear

I am curious why you would want to do a one-motor drive for the long axis. Is that not more difficult to keep aligned than a symmetric drive?

>>I started C & G Associates (now a part of Thermadyne) and designed several cutting machines over the years as well as tracing and drive retrofits. Most early cutting machines were cantilever, single side drive setups. Single side drives are simpler to build. However as you will see from the pictures, they have a "delta" style frame wherein the main rail is longer than the slave side rail. One uses two sets of "side guide" bearings to control the squareness of the main carriage. The first set is in the front roughly in line with the cutting torches; the second set is behind the first pair by maybe 3 feet in the case of a 4 foot wide machine.

You must be sure that the main rail is straight throughout its length. So now as the carriage rolls from front to back, the two sets of side guide bearings maintains squareness thru the entire travel. One can assure straightness by using a piano wire spaced off the main rail by maybe 1/8 inch, front and back. We used a small optical magnifier which had a graticule engraved in the optics, so we could see a .005" variation in straightness. I took some pictures for an eralier inquirer and could send them to you if you want.

For oxyfuel operation this style machine will work very well. We sold single side drives for plasma operation as well. For larger, heavier machines, and faster (plasma) operation, dual side drives are superior.

One of the small machine we made, the one shown as "PlasOpBack", we actually had (2) gear racks setting teeth-up on the top of the table; a single motor-gearbox drove both sides through use of a long cross-shaft with pinions on each end contacting left and right side racks.

Please consider the new conceptual drawings:

Thanks,

Marcin

Regards, Jack C.

DIY CNC Yahoo Group

Marcin: Hello,

I am looking at Xylotex.com 425 in oz motors to drive the long axis of a 4'x8' torch table. I'd like to use a 3/8" pitch by 1/2" wide belt that functions as a rack. The pinion is a pulley of 2" diameter. I'd like to have one drive motor on each side of the long axis.

Would I be able to drive the pulley directly with the motor, or do I need some gearing on the motors?

I've considered ball screw assemblies, but it appears that I don't need such high accuracy, and simple belt drive will get me at least 1/30 inch accuracy on the torch table, if I don't use microstepping. Are the 3/8" pitch pulleys sufficiently accurate for this? I am trying to do the rack-and-pinion belt instead of ball screws for lower cost:

http://openfarmtech.org/index.php?title=Torch_Table

Sincerely,

Marcin blog.opensourceecology.org/

Response 1

Marcin,

I looked at the website/blog pretty interesting stuff, you are doing your homework.

To do to it right, you need to do some motion analysis on your drive setup. The gear ratio you will require depends on the weight (mass) of your carriage. If you look at the big commercial makers, you will see that they have a reduction between their linear drives (mostly gear rack) and the motor output. The reduction needed depends on the reflected load inertia to the motor, the inertia of the motor itself and the power (torque curve) of the motor. There is some free to use motion control analysis software out there that you can download and do this analysis with.

Another hint - if your drive system is rigid, you have to use microstepping. Otherwise you may miss steps. If your drive system is sloppy and the gantry inertia is very low you may be able to get by without microstepping. Otherwise it is required.

I'd probably look at 1/4" pitch belt for better accuracy. 3/8 is a little coarse but it might work fine also. If I were to do a one off table for myself I'd take a good look at roller chain for the long drives. I think it might be cheaper than belting overall and perhaps more rigid.

Good Luck,

Dave

Response 2

Marcin, I have a few comments.

I very much recommend against the round rails. Use linear guides, second hand if you cant afford the new ones. The round rails will bend appreciably with the forces you get when using a router on wood or an end mill on metal. I know most hobbyists use them - but that does not mean its a good idea.

Mxl timing belts may not be strong enough.

Accuracy is not you problem, strength is.

Mxl is not able to transmit the power you need at the speeds you need.

Timing belts strength are dependant of speed - when cutting, your

effective rpm may be well under 10 rpm.

At that speed mxl and xl are simply not strong enough.

Use HTD pulleys and belts, 15 mm width, 5 or 8 mm pitch. They are stronger, transmit more torque and would be a much better choice. They are very accurate, more than you require. Note that the belts are put on quite tightly for 8 mm htd. If they are slack, they wont work nearly as well or accurately.

Use microstepping. Its really, really important. Don´t even consider non-microstepping solutions.

The motors are good for this application. Proper tensioning of the belts means that you overload the axels on the Nema 23 motors - they don´t fail immediately,but they may have a very short life.

Its more work, but a bearing and coupler will make it a much better solution.

The design is classical, well proven, and should work very well.

Response 3

A friend of mine has a CNC plasma table and the X axis (gantry type) uses 2 nema motors with gears and a toothed track. No gearing or long belts. Works "real" good.

Xylotex Yahoo Group

Re: [Xylotex] Direct belt drive for 4'x8' torch table

On Friday 08 February 2008, marcin_ose wrote: >Hello, > >I am looking at Xylotex.com 425 in oz motors to drive the long axis of >a 4'x8' torch table. I'd like to use a 3/8" pitch by 1/2" wide belt >that functions as a rack. The pinion is a pulley of 2" diameter. I'd >like to have one drive motor on each side of the long axis.

2" might be a pretty good load, acceleration profiles would need to be tweaked. What does the proposed carriage weigh?

>Would I be able to drive the pulley directly with the motor, or do I >need some gearing on the motors?

Direct, unless that would exceed your target rapids speed. The 425's are a bit slower than the 262's. The accel profiles will be slow, probably at least a second to full speed if that is as heavy as the drawing implies. Full speed will be tooling right along mind you. Much faster than the torch can cut. :)

>I've considered ball screw assemblies, but it appears that I don't >need such high accuracy, and simple belt drive will get me at least >1/30 inch accuracy on the torch table, if I don't use microstepping.

I would definitely use microstepping just for the smoothness in motion it imparts. Faster accelerations can be achieved when you aren't asking the motor to do a full step if its motion is constrained by a high inertia load such as the carriage of a 4x8.

>Are the 3/8" pitch pulleys sufficiently accurate for this? I am trying >to do the rack-and-pinion belt instead of ball screws for lower cost:

I would think so, but tension might be critical for backlash control, and I'd think a plastic track to support the bottom, return run would be helpful as it would reduce whipping. As would of course some method to keep the debris out of the works.

I wasn't aware that those belts were available in those lengths as you would need around 17 to 18 feet in linear measure, twice.

>http://openfarmtech.org/index.php?title=Torch_Table

I think I would replace those heavy guide rods on the carriage with even larger and more rigid thin walled pipe as it would reduce the traveling weight. Fawncy linear bearings can be replaced with triplets of sealed skate wheel bearings for both cost reduction and some weight reduction. For the bed rails too for that matter. To help keep dual motors in step, I'd want to face the rears toward each other and couple them together with a long hollow drive shaft but that's just me. Two separate homing switches would probably work just as well though. If the motors get out of step in actual operation, you have a tuning problem in the software anyway.

A neat idea, I wish I had room for something like that.

>Sincerely, > >Marcin >blog.opensourceecology.org/ > > > > >Yahoo! Groups Links > > >

--

Cheers, Gene

"There are four boxes to be used in defense of liberty:

soap, ballot, jury, and ammo. Please use in that order."

-Ed Howdershelt (Author)

You have a will that can be influenced by all with whom you come in contact.

Arnar Mar Sig, Iceland Fab Team

Power, Speed, Accuracy

I was thinking about using steel for the main support frame welded together at the joints, but it would be easy to change that part to bolt together type. The Y and Z axes would be made from aluminium bolted together. The reason for the steel frame is to get maximum support and stability if the axes are moving fast.

You can post it and get input as you want, Its open source;)

The reason for linear bearings and screws on the X axes is so i dont have to move a big and vibrating motor with the axe. This is propably the biggest motor on the table. Also using the design that torchmate uses then we need 2 motors on both sides.

The most expensive part of the controller board are the power transistors. If one didin't need the 30-50V 6A output then we can change to smaller transistors. Also i have dedicated stepper motor IC's to control the critical timing so its a bit more expensive then using a generial purpuse microcontroller like most designs use, but thous designs can't step really fast. Also many other "open" router table designs still relay on proprietary controllers.

I will most likley use Olimex (http://www.olimex.com) to fab the PCB it costs 30euro to fab 1x 100x160mm board. I can do single sides boards at my shop but this board has to be double sides.

The controller board has a small 8-Bit AVR to communicat with the dedicated IC's and a computer. I haven't started the code but its really simple and written in C and small parts in assembly. The controller will communicat thru RS232 or Ethernet (if we add that option, and it would be really nice to have). The controller will be able to take in simple commands like "Move this axe to position X at Y speed", so it will be able to work standalone without Smari's routing software.

I haven't found any open source controller that has the power, speed and accuracy i want, thats why i'm doing this design.

Basic electronics specs

When building the router you should be able to use almost any Bipolar stepper motor that has the power to drive the mechanics. I'm designing the motor driver now, the specs are: Support for 3x Bipolar steppers, 30-50V max 6A (200-250W) Input for 3x incremental encoder for step verification and currection. Max step freq of 20kHz RS232 port for programing (Maybe USB)

The board will probably cost between 300-400$us to make.

If you have any input on the design or the machanics then please tell.

Capacities

I just started drawing the CNC rouer in Solidworks yesterday. The basic version will have 3 axes with an changeable head. The head can be a cutting head, plastic extrude, acetylene/plasma cutter. (The head could also add another axe for 4-5 axe version). I was also thinking about adding fittings to be able to add a rotating spindle to do CNC lathe work.

I've started the design of the motor drivers as you know Smari and I can probable finish the design and send the pcb out to fabrication this weekend.

Casting aluminium isin't so hard. Making the molds is also simple and cheep, just expanded polystyren and plaster. Molds can also be created in sand, but its not as good. Casting carbon fiber is almost like doing fibreglass, you can do it at home buts is messy.

Project Budget and Goals

Arnar,

I like the one motor design. I think the Torchmate drive system is more complicated, such as the one motor on each side.

Tell me more about the power transistors. What is the particular transistor you're using? Can you redesign to simply use a larger number of smaller transistors, or is that ineffective?

So look at the budget:

1. Structural steel - $400

2. Control board - $400

2a. Encoder - $100 for each axis - if needed

3. Control software - free

4. Stepper motors - $100, main

5. Stepper motors - $100, 2 smaller ones - from Xylotex

6. Ball screws - 13 feet total plus 3 ball sets - $300?

7. Linear bearnings and shafts: 26 feet - $300?

I just sent for a quote to Nook Industries for the parts in the XYZ-table diagram, http://openfarmtech.org/index.php?title=Torch_Table .

Those last two are my guesses, but that's about $1600 - 1900 total?

What kind of accuracy are you aiming for? The ball lead screws from Nook Industries are down to +-.0004 inch. I would need only .01 for the purposes of CEB. Have you considered simple threaded rod? It's $23 for 10 feet of 1/2" rod, part 98935A632 at http://www.mcmaster.com/ . Or, $40 for precision threaded rod, 6 feet of 1/2". The precision rod is down to .009 inch accuracy per foot of travel. That would do for me.

Then again, if one attached 2 nuts to a simple threaded rod, the backlash (play) would decrease. That may be another route for the cheap way.

What do you do professionally? Are you an electrical engineer?

Are you looking to neo-commercialize (see http://www.p2pfoundation.net/Neocommercialization ) the XYZ table? Are your goals similar to mine, like the open franchising of the CEB press - http://openfarmtech.org/index.php?title=CEB_Press ?

Marcin

Encoders, electronics component prices

I took together the parts needed and checked the prices. The full controller with all features will cost about 307$us (ordering components for just a single unit). By removing the Incremental Encoder support (and also decreasing accuracy), the unit can be build for 232$us. After checking the prices i found that the transistors aren't that expensive. You can cut the number of transistors used to 12 and then only having max 3A output, but the price is only 17.76$us lower.

That budget looks about right, the only thing missing are the incremental encoders if one wants to use them, they are about 50-100$us for low end 1024tick/rev, 3 are needed. I was hoping to build this for between 2-3k (a bit more expensive to build in iceland)

I want to be able to mill PCB boards with this router, so 0.1mm (.003") is the minimum accuracy i want, but having down to 0.0004" would be awesome. For most DIY people a simple threaded rod and bolt would do. I want this do be a "neo-commercialize" project. All the hardware, mechanical and software designs should be open source and everybody should be able to build the machine and use the parts they want (skipping encoders, using threaded rods.. etc) to get the accuracy the want, but I still want to be able to sell complete machines with the best accuracy we can get (hense everything is deisgned for maximum accuracy).

I do Software programing and electrical designs for Valka (www.valka.is). We make fish processing machines.

Guide Rails, Encoders

Just talked to Nook Industries. I was told that the linear bearings and shafts are about twice as expensive compared to profile guide rails, so I'll get a quote on that plus ball screws and pass it on. Just a data point.

We can redesign structure easily if needed, by just replacing the linear shafts with linear rails. The rails are supported on their whole length, as opposed to linear shafts, which are supported at the ends.

Their turnkey package for motors, controllers and encoders is under $5k. So looks like your work is Factor 10 Engineering (http://www.10xe.org/). I love it, because $500<$5k. In my language, that's 10 times more freedom.

Electronics, BOM

Hi Marcin

I buy most parts from Digikey, the TMC* parts i will probably buy from semiconductorstore.com or some other place if i find them.

I'm going to redesign the router to have at last the X and Y axes on profile guide rails and cut costs a bit.

Yes, its a Open Office spreadsheet. You can open it with OpenOffice on Mac, i find it a bit less of a crap then Microsoft office on mac, but it still sucks.

Your right, its simpler to driver a unipoler motor and most DIY projects choose to use them. Bipoler motor has one winding per phase while a unipoler has 2 winding per phase, but at any given moment there are only 2 windings in use. This makes a unipoler motor with the same torque as a bipoler motor bigger, heavier and more expensive then bipoler. You can also buy steppers that are hybrids and can be driven both ways.

The driver IC's i'm going to use take care of the motor driving so it dosen't matter much in the end except for cheeper and less heavy motors:)

Arnar,

Can you resend partlist.ods? I'm just getting a blank page.

Xylotex has 23 Nema motors at $50, http://www.xylotex.com/StepperMotor.htm, so that's cheap. Are those the type you plan on using? If it's got two phases, that makes the 6 amps you're talking about?

Have you considered power scaleability by attaching 2 (or more) double-shaft motors one behind the other? That would be a good feature for high power, such as lathing, or even adopting a similar design to milling. Is your controller capable of being paralleled, such as using 2 (or more) controllers to drive the additional motors, so we can scale the power completely? That would be a useful feature from the standpoint of scaleability. This would be quite exotic to have, and I always aim for such. For example, the Boundary Layer Turbine is absolutely power scaleable by virtue of adding disks: http://openfarmtech.org/index.php?title=Boundary_Layer_Turbine

So your strategy is to put the complexity into electronics and not into the motors, as electronics are cheaper, right? That's the same strategy as hybrid electric cars: rip out the transmission and replace it with electronic torque control such as PWM.

Marcin

Bill Swann

I talked to Bill Swan, product designer from Texas, after I saw an XYZ table that he made. ; 7138271503; 8323383080(c). Dbswann4@yahooo.com.

He told me about Nook Industries. Basic design includes:

Shawn Kelly

<bluumax@yahoo.com> date Jan 23, 2008 4:43 PM

Hi Marcin. I would really suggest a Xylotex drive or other known professional drive. I use the Xylotex for my Taig mill. [1] They cost about $500 with motors, but you get $500 worth. I wouldn't trust many drives I see on ebay to run a "real" mill / router table. There is also the Linistepper kit for unipolar motors. I know these work. Cost is about $100 for 3 axis [2] CNC software will run standard G code that is output from CAM to the machine. G code is machine commands & machine coordinates. I use Corel draw to make the parts, save as .DXF & convert to g code using Lazy CAM, part of Mach3 Mach3 actually runs the mill table. [3]

The software (turbo CNC / mach3) reads the g code & feeds it to the Xylotex drive. I'm in a studio apt now so I can't build anything big. There's a lot of stuff on ebay & [4] is a really good place to look.

$50 for Torchmate 3 size stepper motors: [5]

Jeff at Xylotex

support@xylotex.com

A 4 X 8 table is quite laqrge, but some people in Canada are driving a similar sized table with Xylotex drives. See a picture here (top rightcorner).

I would recommend running with 2 leadscrews on the side rather than one down the middle. This way your center, cutting area does not have the leadscrew in the way.

If you use 10 tpi screws with the 269 oz.in. motors you should get around 75 IPM on a system with smooth running ways. You might be better off with 5 tpi screws and then use the 425 oz.in. motors, though.

You can use turboCNC OR Mach, but mach will provide "slaving" which allows two motors to be driven on the same axis. I'd recommend use Mach if you do decide on the recommended dual leadscrew design.

If you use Linux, then I would recommend EMC2.

The 425's with 5tpi will give a faster movement. You need this with Plasma Torches (when cutting thin metal) to keep from destroying the work. 269's with 10 tpi will give a decent speed, but with plasma you need the speed, and the 425's would give better result I think. I haven't tried the 269's with a 5tpi screw. They might work just as well, since there really isn't a large load to move with plasma tables (i.e. no cutting forces to overcome). A 5 tpi screw may have the same diameter as a 10 tpi screw, so rod thickness wsn't a consideration.

I don't know if EMC2 has the capability to "slave" one axis to another. This could be done using an external break-out board and wiring the A signals over to the X. Another option would be to copy all X movements in a program so they will be X and A movements. This would be an option for small programs, or if you have a good search-and-replace program.

Jeff

Other

Parts Sourcing and Specifications

- Specifications of different size motors. NEMA 42 is the largest.