Hab Lab

The need for all-weather housing to shelter year-round members of the community, located where summers can be unpleasantly hot and winters unpleasantly cold, can be met with superinsulated designs. Here we will examine some possible options and our progress in bring them into existence. Planning tools, instructions, modifications, etc. will be included.

The Design Page is a good place to see what has been offered and to post any of your own great ideas. More ideas are great for everybody!

Survey & Design

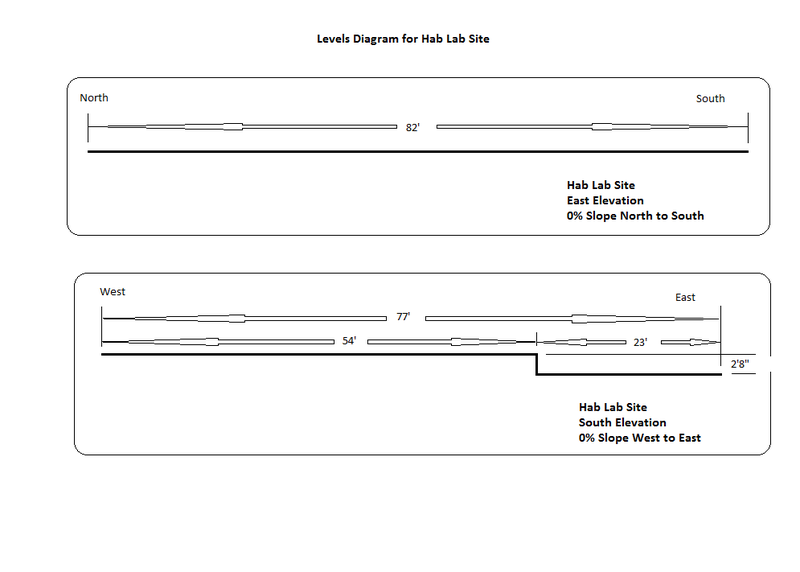

The area on the property for the first group habitation was on a noticeable slope. OSE staff members worked with a home-made water level to take measurements over a 100' square area.

How to make a water level: http://www.youtube.com/watch?v=nAcT_1T25LM

Ideas submitted for this project are located on the Hab Lab Design Gallery page.

Building Orientation

Oops! Some of our pads got set 3' South of their intended site. Here is an emergency redesign idea.

Planning

Kitchen/Bath Water

Utility/Storage Area

Heating

Source Material

http://dnr.mo.gov/pubs/pub781.pdf

Site Preparation

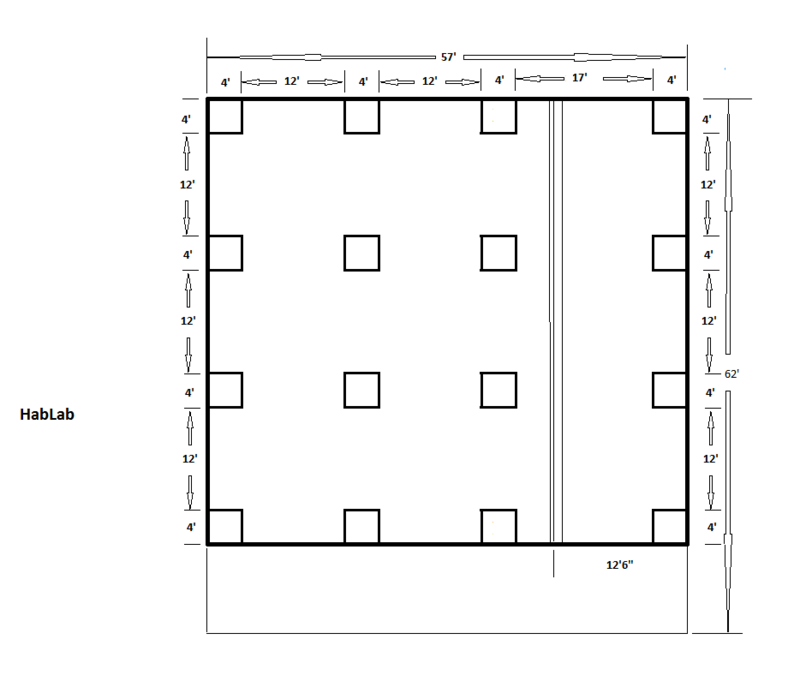

The Hab Lab is designed to be supported by columns built of CEB (Compressed Earth Block)which are constructed on a reinforced concrete pad. Due to the slope of our site, we designed a lowered section which requires a low retaining wall. Included here are instructions for preparing the site with adequate footings.

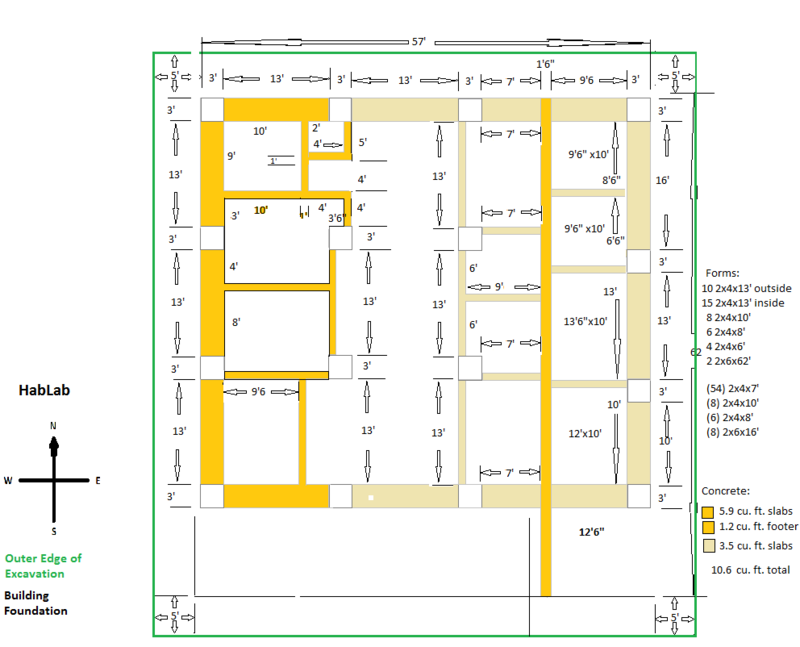

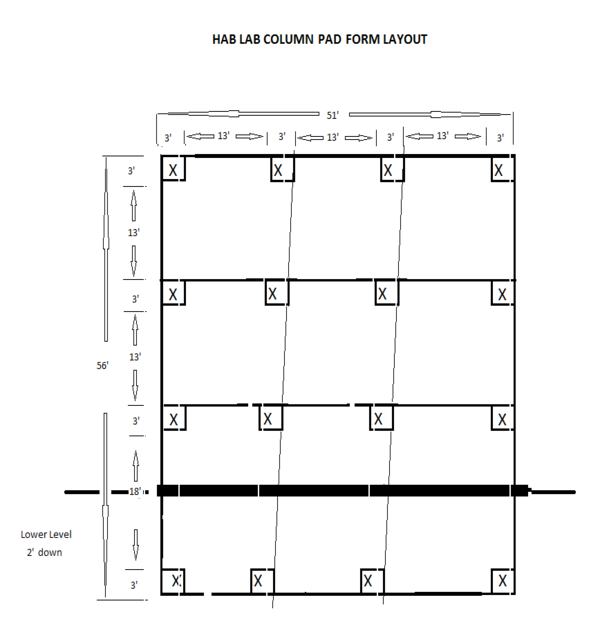

Here is a picture with a preliminary excavation layout for the column pad sites and the retaining wall in the Hab Lab.

- When you are laying out the excavation site, be sure to add 5' in each direction for the excavator to work to.

This levels diagram is from our theoretical measurements - we actually wound up with a 2' drop, not a 2'8" drop. That will make only a minor difference in raising the building - changing the size of the retaining wall and removing one or two CEB's at the top of the lower columns to maintain the planned roof pitch.

Foundations & Column Slabs

Laying out the Hab Lab excavation site to be square

Collect equipment and supplies needed

- Blueprint of site plan

- (2) 100’ Measuring tapes

- 4 3-4’ stakes

- Hammer

- Bright spray paint

Steps for Staking out the excavation site.

- Choose a spot approximately 5 feet to the North and 5 feet to the West of the area to be excavated.

- Pound in a stake and spray paint the top foot or two of it.

- Measure due East a distance 10’ longer than the foundation width (total 67’).

- Place and paint another stake.

- Calculate a distance 10’ longer than the foundation length (total 62’).

- Calculate the diagonal measurement of the excavation site [Length(squared) x Width(squared) = Diagonal(squared)] (91'4").

- Measure due South from the Northwest stake the distance calculated in step 6.

- Set the second tape measure on the Northeast stake and measure the diagonal calculated in step 7 going Southwest.

- Set your third stake where the two measured lengths meet each other.

- Paint the stake.

- Measure due South from the Northeast stake the distance calculated in step 6.

- Set the second tape measure on the Northwest stake and measure the diagonal calculated in step 7 going Southeast.

- Set your fouth stake where the two measured lengths meet each other.

- Paint the stake.

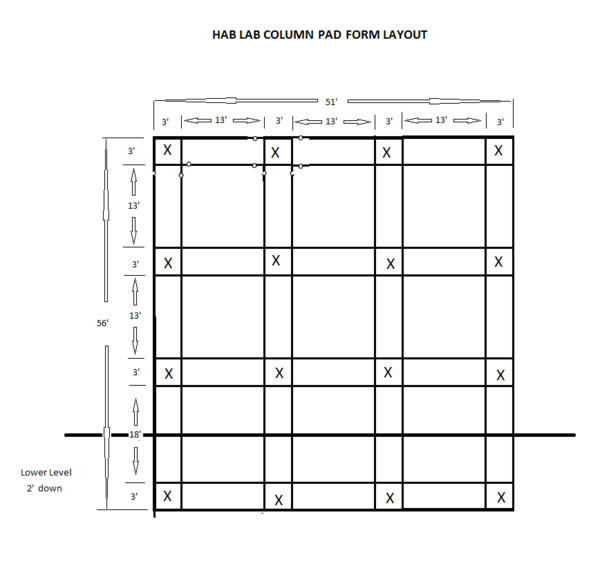

- With the site leveled, the foundation holes for the column slabs must be laid out.

- After excavation, the stone fill for the foundation goes into the holes.

- At the same time, the 6" stone floor foundation is spread.

Concrete forms and rebar reinforcing assemblies

These can be built well ahead of need whenever volunteers are available.

- You could set up an assembly line effect to do them all at once with several people working together.

- An individual might do one unit at a time.

- An individual might do all the wood cutting at one time, another do all the rebar cutting at another time, another do all the rebar bending at another time.

- A couple of people might work together to get some wooden forms assembled once the pieces are cut, another time, a couple of people might work together to get some rebar assemblies welded.

The following step-by-step instructions are provided for building the forms and the reinforcing rebar assemblies.

[Assembly sheet for column pad forms]

[Rebar plan for column footings]

Laying out the locations for the forms on top of the foundation stone

Once the form and rebar assemblies are built and the foundation stone is in place, the string site plan lay-out must be set up for placing the forms properly over their (now invisible) foundations. If you set your hole locating strings far enough out that the excavation didn't disturb them, this will be simple. It will be even easier if you rolled up your strings before the hole excavation got done and saved them. (See comments below!)

Collect equipment and supplies needed

- Blueprint of site plan

- 100' tape measure

- Pre-placed marking stakes around outside of foundation site.

- Rolled up pre-used string balls from foundation hole layout

Steps for Laying out Column Pad Form locations.

- Measure to check that all pre-placed marking stakes are properly positioned.

- If any are missing or misplaced, replace or reposition them as needed.

- Unroll and retie the strings to their corresponding stakes across the foundation site .

Here's what the layout over the stone should look like.

-Note- We had a great plan for this - we would set our stakes out first to mark the hole edges at 4'x4', save the strings and move the stakes in by 6" to 3'x3' for the setting the pad forms.

However, when we tried it in real life - Well...

- We lost a lot of our stakes during the excavation.

- We found the holes tended to come out bigger than we had intended them to be.

- And once the stone was laid over the site, we couldn't see where the foundation holes were located!

We wound up remeasuring and resetting most of the stakes for laying out the pad site grid.

- We dug stone out of two of corners to find the edges of the foundation holes.

- We remeasured and reset corner marking stakes inside those edges.

- We retriangulated with the diagonals to assure the foundation square.

- And we remeasured and reset stakes along all the edges.

So we've rewritten the foundation lay-out plans as they are currently posted. In the current version, we set the stakes at the 3'x3' points to start with so they don't need to be moved. We also emphasized setting them firmly - and safely outside the excavation area.

-Later Note- More sad experience - gained while setting the floor and wall forms and found our firmly set concrete East column pads were sitting 3' further South than they should have been!

What happened -

- The outlining strings for the site were set properly and square - good.

- However, while doing all of the fixing above, we got tired and thought up a short cut. We were short on stakes and we needed to mark both the hablab and the workshop sites for form placement (our 40 forms would require us to locate and put in some 40 stakes) We could place our forms easily enough in line with the strings with only one corner marked couldn't we? (That would require placing half as many stakes!)

- We started at the NorthWest corner and measured 16' East along the North line and staked that for a line. Then another 16' East we set another stake.

- Then we went back and did the same from the NorthWest corner to the South. - and from the SouthWest corner to the East.

- Finally we went down to the lower level and marked the East line of the site starting at the South end of the line. - And we ran our strings.

- Later, we were tired and losing daylight when we set the forms in place along the lines on the Hab Lab site.

I suppose this short cut could have worked if we had checked more carfully:

- Rechecking the placement measurements is an obvious one.

- Standing back and looking for parallel lines is another obvious one.

- Looking for a cause when it was difficult to align the squarely built pads with the crossed strings would have been another solution.

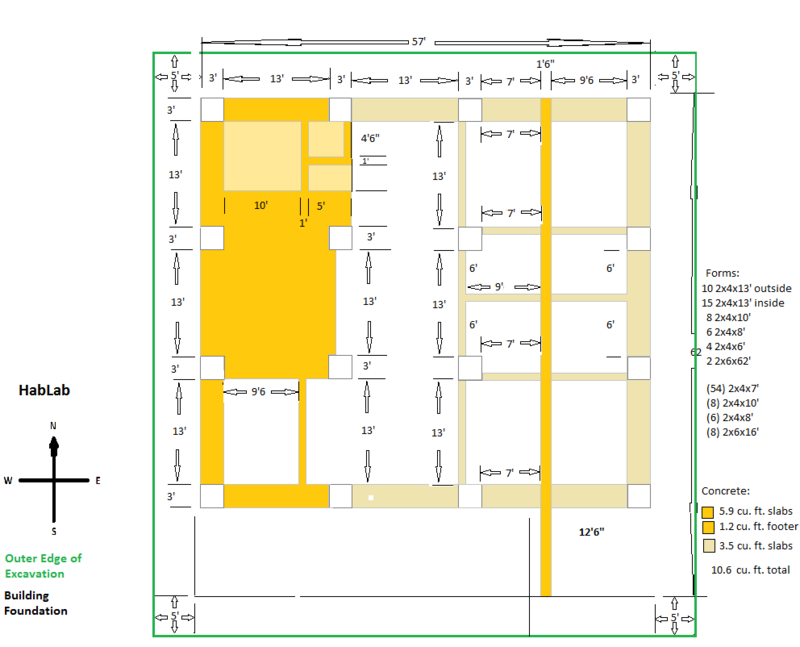

So this is the layout we are actually working with now!

We decided that an emergency floor plan change we came up with should compensate for this without having to redo most of the column pads. As we run into more complications, we'll post on them!

Setting the column pad forms

Collect equipment and supplies needed

- Supplies

- 16 Pre-built column pad forms

- 80 form stakes (we used 2"x2"x18" wooden stakes)

- Equipment

- Heavy Hammer(s)

- 4'spirit Level

- Water level

- tape measure

Steps to place Column Pad forms

- Use with the center pad site on the upper level as the reference pad.

- Set a pre-built column pad form in place under the string lines with the inside of the forms under the strings.

- Drive two form stakes next to the outside of one side and one on each of the other three sides. They will need to sit deep enough that the tops of the stakes will be level with (or lower than) the top of the form.

- Level the form.

- Screw one of the stakes (on the side with two) to the side of the form so that the form sits 1/2" above the gravel level. Be sure that the top of the stake is level with (or lower than) the top of the form.

- Use the spirit level to set this side of the form level and screw it in position.

- Use the spirit level to set the opposite side of the form at the same level.

- Check the level on the other two sides and screw them in place.

- Use the water level to set the first level on each of the other pads on the upper level.

- Repeat the remainder of the leveling steps for each form.

- Use the water level to set the level of the center form in the lower level at 24" lower than the upper level pads.

- Complete the leveling steps for this form.

- Use the center form on the lower level for a reference form to set and level the remaining lower level column pad forms.

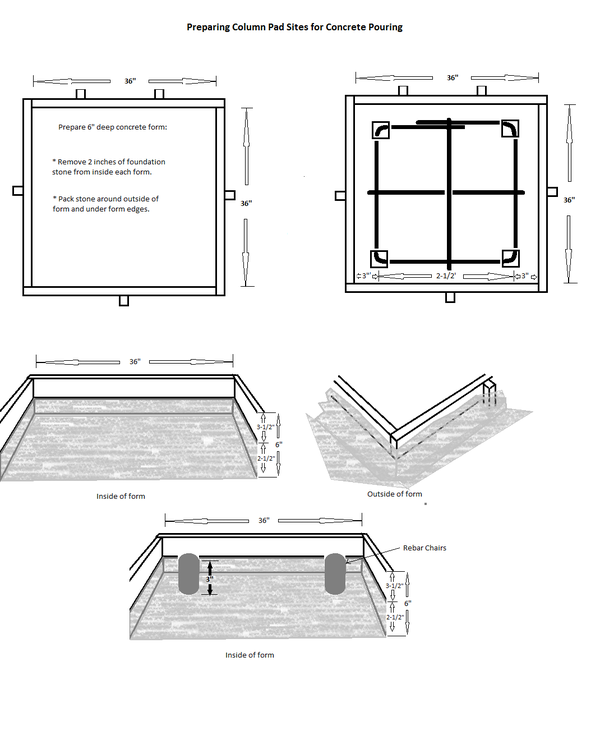

Preparing Column Pad Forms for Reinforced Concrete

Collect equipment and supplies needed

- Supplies

- 16 Pre-built column pad rebar assemblies

- 64 rebar chairs

- Equipment

- Rake(s)

- shovel

- tape measure

- Use a rake and shovel to remove about 2" of stone from the inside of the form. (until is 6" deep)

- Pack removed stone around outside of forms to create a fully enclosed 6" deep form.

- Use one prebuilt column pad rebar assembly for each column pad site.

- Center the rebar assembly with 3” gap between assembly and form wall on every side.

- Set rebar chairs under corners of prebuilt column pad rebar assemblies.-Put a stone or some gravel under the chairs if needed to center the rebar so it will sit at about the middle of the finished slab (3" off the floor of the form).

Concrete Work

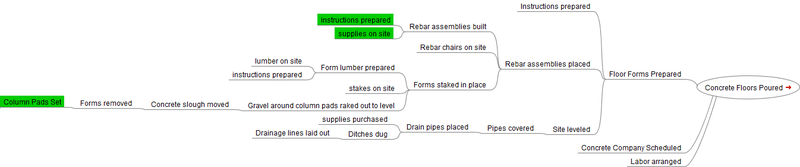

We are preparing to do the big concrete pour. Using the FreeMind mind map model, this is the node that outlines the dependencies so we can be ready for that. Following sections include instructions for accomplishing them.

Here is the planning layout for the concrete - which we are planning to do in one great big pour. We'll let you know how it goes!

Insulated Outside Wall Support Slabs

We are planning to put reinforced concrete the full 3' width of the Column Support Pads all the way around the outside of the building. They will be 3-1/2" (2x4 lumber size) deep and will support the two CEB walls that enclose the hay bale insulation. Rebar assemblies and concrete form sizes can be prepared ahead of time.

Preparing the rebar reinforcement assemblies

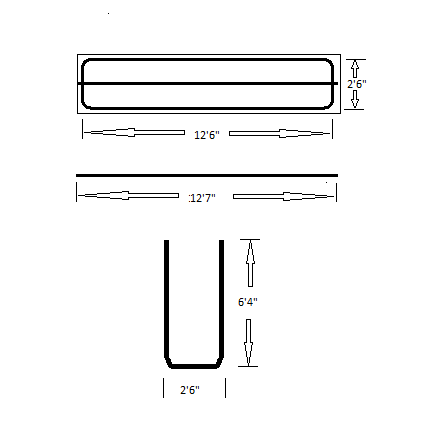

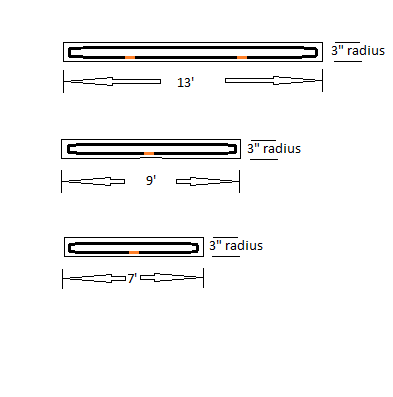

Rebar Assembly for 13’ Outside Wall pads (make 11 assemblies)

Collect supplies and equipment

- (3) 20’ lengths #4 rebar

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (2) 20’ lengths of #4 rebar 6’4” from one end.

- Bend at a right angle.

- Measure and mark each piece to bend into a U shape with 2’6” between the legs.

- Bend them into (2) U shaped pieces.

- Measure, mark, and cut the long end of each U to the same 6’4” length

- Measure and weld the two assemblies into a single rectangle of 12’6” by 2’6” dimensions.

- Measure and cut (1) 20’ piece of #4 rebar to 12’7” in length.

- Center the 12’7” piece between the long sides of the rectangular assembly.

- Weld it into place.

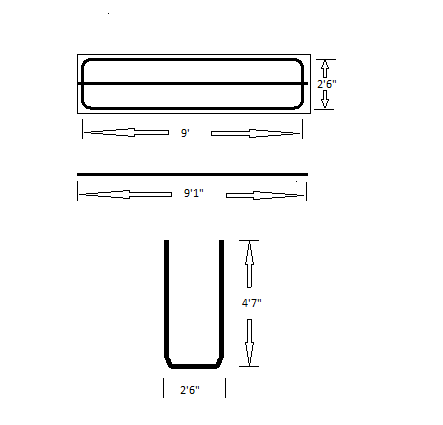

Rebar Assembly for 9’6” Outside Wall pads (make 2 assemblies)

Collect supplies and equipment

- (3) 20’ lengths #4 rebar

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (2) 20’ lengths of #4 rebar 4’7” from one end.

- Bend at a right angle.

- Measure and mark each piece to bend into a U shape with 2’6” between the legs.

- Bend them into (2) U shaped pieces.

- Measure, mark, and cut the long end of each U to the same 4’7” length

- Measure and weld the two assemblies into a single rectangle of 9’ by 2’6” dimensions.

- Measure and cut (1) 20’ piece of #4 rebar to 9’1” in length.

- Center the 9’1” piece between the long sides of the rectangular assembly.

- Weld it into place.

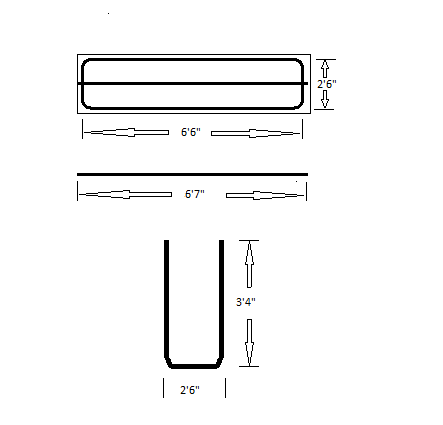

Rebar Assembly for 7' Outside Wall pads (make 2 assemblies)

Collect supplies and equipment

- (3) 20’ lengths #4 rebar

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (2) 20’ lengths of #4 rebar 3’4” from one end.

- Bend at a right angle.

- Measure and mark each piece to bend into a U shape with 2’6” between the legs.

- Bend them into (2) U shaped pieces.

- Measure, mark, and cut the long end of each U to the same 3’4” length

- Measure and weld the two assemblies into a single rectangle of 6’6” by 2’6” dimensions.

- Measure and cut (1) 20’ piece of #4 rebar to 6'7" in length.

- Center the 6'7" piece between the long sides of the rectangular assembly.

- Weld it into place.

Preparing the concrete forms

Our pouring plan requires these forms relating to the outside wall construction. For those wall pads that are part of our interior pads, additional forms are in other sections. If you are not pouring large interior pads, you will need to adjust the number of interior forms.

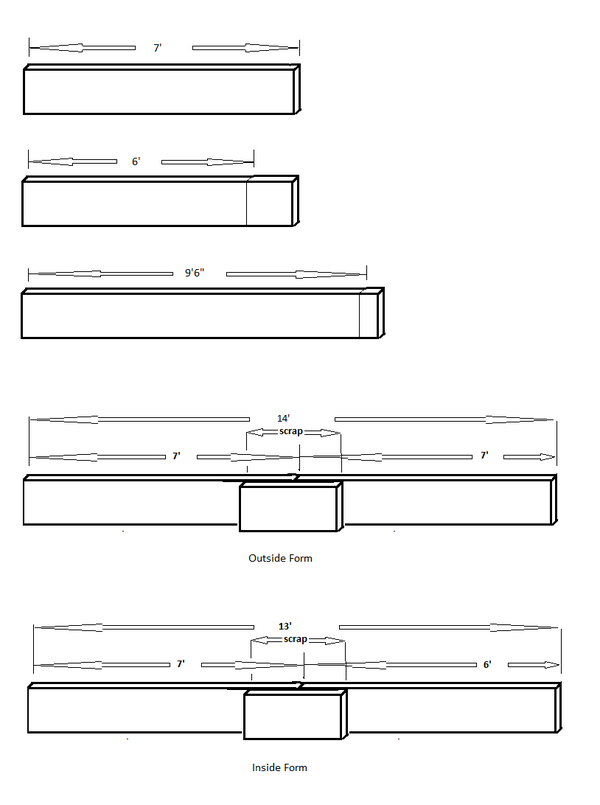

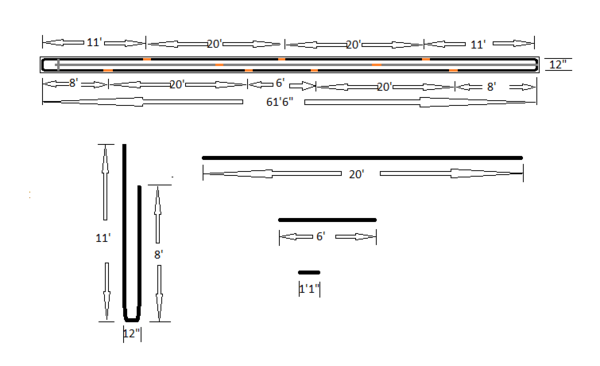

Exterior Forms for 13' Wall slabs. (make 10 assemblies)

Collect supplies and equipment

- (2) 2"x4"x7' pine studs

- (1) piece of scrap lumber,

- (4) 3" screws

- Driver

Steps to do:

- Start two screws into the flat side of each end of the piece of scrap lumber.

- Butt the two 7' boards end to end

- Lay the piece of scrap lumber over the seam butt joint.

- Be sure the narrow sides of the boards are lined up evenly with each other.

- Drive the screws in completely to hold the boards in line.

Interior Forms for 13' Wall slabs. (make 5 assemblies)

Collect supplies and equipment

- (2) 2"x4"x7' pine studs

- Measuring tape

- Pencil

- Saw

- (4) 3" screws

- Driver

Steps to do:

- Measure, mark, and cut one board to be 6' long.

- Start two screws into the flat side of each end of the 1' piece of scrap lumber.

- Butt the 6' piece with the other 7' board end to end

- Lay the piece of scrap lumber over the seam butt joint.

- Be sure the narrow sides of the boards are lined up evenly with each other.

- Drive the screws in completely to hold the boards in line.

Forms for Wall slabs on split-level section

Collect supplies and equipment

- (6) 2"x4"x7' pine studs

- (4) 2"x4"x10' pine studs

- Measuring tape

- Pencil

- Saw

Steps to do:

- Measure, mark, and cut (2) 7' boards to be 6' long.

- Measure, mark, and cut (2) 10' boards to be 9'6" long.

- You will use the other boards uncut.

Setting the forms

Narrow Wall Support Slabs

We will support and stabilize the interior CEB walls with a 12" wide x 3-1/2" deep concrete slab. Rebar assemblies and concrete form sizes can be prepared ahead of time.

Preparing Rebar reinforcement assemblies

Rebar Assembly for all 12” interior wall slabs

Collect supplies and equipment

- (10) 20’ lengths #4 rebar

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (2) 20’ lengths of #4 rebar 3’4” from one end.

- Bend 180⁰ the rebar with a 3” radius.

- Measure and mark so another 180⁰ with a 3” radius will produce 6’6” long assemblies.

- Cut the extra rebar (about 7’) off, leaving enough to tack weld each assembly together.

- Measure and mark (4) 20’ lengths of #4 rebar 4’4” from the end.

- Bend 180⁰ with a 3” radius.

- Measure and mark so another 180⁰ with a 3” radius will produce 8’6” long assemblies.

- Cut the extra rebar off, leaving enough to tack weld each assembly together.

- Measure and mark (4) 20’ lengths of #4 rebar 6’4” from the end.

- Bend 180⁰ with a 3” radius.

- Measure and mark so another 180⁰ with a 3” radius will produce 12’6” long assemblies.

- Use scrap cuttings (about 7’ long) to bridge the gap for each of these assemblies.

Preparing the Concrete Forms

These 12" wide slabs will provide a firm foundation on which to build our interior CEB room-dividing walls. Mostly they use the same sizes of forms you used for the outside walls. If you are pouring in small stages, you won't have build more forms because you can reuse the ones from the outside wall slabs. If you are going to pour all the concrete at once, you will need 7 more of the 13' inside form assemblies, 4 more uncut 7' boards, 2 more 7' boards cut to 6' lengths, 6 more boards cut to 9'6", and two boards cut to 9' in length. Instructions for preparing all of these boards are found above - in the Outside Wall Slabs section.

Setting the Forms

Kitchen and Bath Areas

The Kitchen and Bath Floor Areas both have a potential for receiving noticeable amounts of water. We consider it advisable to pave them both with concrete and include a central drain. Rebar assemblies and concrete form sizes can be prepared ahead of time.

Preparing the Rebar Assemblies

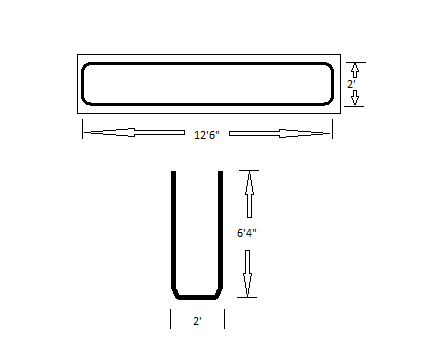

Rebar Assembly for 16’x13’ slabs (make 2 assemblies)

Collect supplies and equipment

- (3) 20’ lengths #4 rebar

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (4) 20’ lengths of #4 rebar 6’4” from the end.

- Bend at a right angle.

- Cut the long ends to 7’10” long.

- Overlap the short ends of two L-shaped pieces and measure to make a U shaped assembly with 12’6” between the legs.

- Make two of these assemblies.

- Overlap the legs of the U-shaped assemblies to make a rectangle measuring 15’6” x 12’6”

- Measure and cut (5) pieces of #4 rebar to 15’7” long.

- Measure and cut (7) pieces of #4 rebar to 12’7” long.

- Space and position the cut pieces into a 24” grid across the rectangle.

- Weld them into place.

There is one more assembly to go into this section between the two big ones. It is a modification of the exterior wall slab reinforcements.

Rebar Assembly for Interior 13’x3’ section of big Slab

Collect supplies and equipment

- (2) 20’ lengths #4 rebar

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (2) 20’ lengths of #4 rebar 6’4” #from one end.

- Bend at a right angle.

- Measure and mark each piece to bend into a U shape with 2’ between the legs.

- Bend them into (2) U shaped pieces.

- Measure, mark, and cut the long end of each U to the same 6’4” length

- Measure and weld the two assemblies into a single rectangle of 12’6” by 2’ dimensions.

Preparing the Concrete forms

Because we are pouring this all at once, we decided to eliminate some complicated form work by including the equipment area and one room in this slab. This will be a big pour of concrete. It requires about 5 cubic yards of concrete. If you have plenty of time and are working in small batches, you can save over a yard of concrete by building the interior wall forms and pouring only wall-support pads - as shown on the layout.

The large slabs are laid between column pads, using 13' interior form assemblies. If you are pouring all at once, you will need two more of these assemblies, one more board cut to 9'6", and a piece of scrap about 3' long to complete the form work for this area. This, of course, assumes that you already have the exterior forms for the exterior wall slabs prepared. Instructions for preparing all of these are above in the Outside Wall Slabs section.

Setting the Forms

Retaining Wall for Lower Level

Ideas for this wall have been through several iterations. At present (Oct. 10th), we are planning to lay a 6" footer, 18" wide and 62' long. On top of that, we plan to put a 12" thick wall of bitumen-protected CEB. For the concrete footer, rebar assemblies and concrete form sizes can be prepared ahead of time.

Preparing the Rebar Assembly

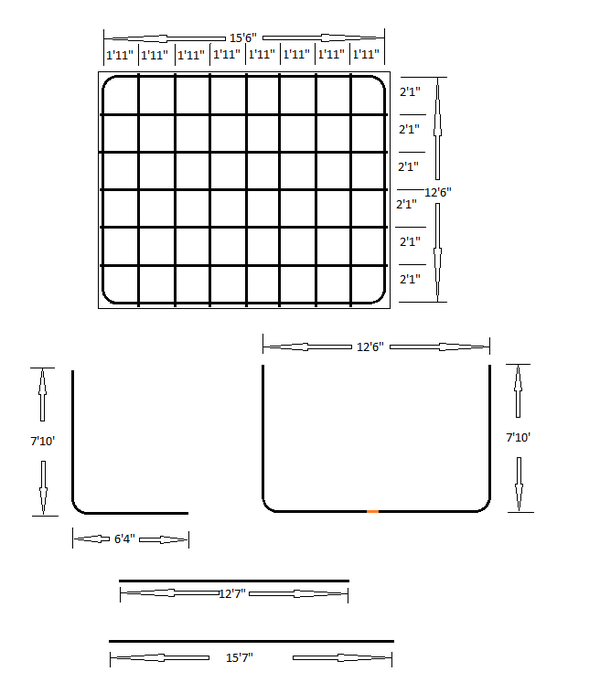

Rebar Assembly for Retaining wall footer

Collect supplies and equipment

- (9) 20’ lengths #4 rebar

- Scrap #4 rebar to make (1) 6’ pieces and (1) 1’1” piece

- Measuring tape

- Marker

- Rebar cutter

- Rebar bender

- Spot welder

Steps to do:

- Measure and mark (2) 20’ lengths of #4 rebar 8’ from one end.

- Bend at a right angle.

- Measure and mark each piece to bend into a U shape with 12” between the legs.

- Bend them into (2) U shaped pieces.

- Measure, mark, and cut (1) 6’ and (1) 1’1” piece of #4 rebar.

- Overlap and weld (1) 20’ length of rebar to each leg.

- Measure and weld the two longer legs together so the resulting assembly is 61’6” long.

- Weld the 6’ piece of rebar between the ends of the two shorter legs so that side is 61’6” long, too.

- Weld (3) 20’ pieces of #4 rebar into an approximately 60’ length of rebar.

- Center the 60’ piece between the long sides of the rectangular assembly.

- Weld one end at the center of one end of the rectangle.

- Position the 1’1” piece of rebar across the rectangle to support the free end of the 60’ assembly.

- Weld the short piece to the three long ones.

Preparing the Concrete Form

This is a really long form - 62 feet. You don't want to put it together ahead of time and try to carry it anywhere! What you do want to do is make sure you have all the pieces you will need cut and reserved against the time you will be setting the forms up.

Collect supplies and equipment

- (8) 2"x6"x16' boards

- (6) Pieces of 2x4 or 2x6 scrap for splicing.

- Measuring tape

- Pencil

- Saw

Steps to do

- Measure and mark 18" from the end of (2) 2x6x16' boards

- Cut the two 18" pieces and mark them "form ends".

- Set aside the 6 16' boards, the 14'6" boards, the form ends, and all the scrap pieces in a reserve pile.

Setting the Concrete Form

CEB Columns

[CEB PDF]

CEB Arches

[Test Hammer] for quality assurance

CEB Floors

Insulated Roof

- 16 11-member 2x6x16' frames

- a layer of tyvek

- a layer of lathe, mounted diagonally about 18" apart

- a layer of hay bales surrounded and around 2x12 spacers

- 16 11-member 2x4x16' frames

- agricultural roof panel on top and sides

Frames are built with one 16' beam on each end of 9 other 16' beams laid on 24" centers. These roof frames can be built quite quickly at any time labor is available, preferably ahead of time so that they can be installed as soon as the columns are ready to be covered.

Super Insulated Walls

2.5 foot thick wall.

4x6x12 bricks laid on the 12x4" side in standard wall layup, two walls outside surfaces 2.5' apart.

With air space left on either side, bales are stacked in the center of the wall, creating super insulation between the interior and exterior.

Heating the HabLab

I propose a [Heatkit] masonry furnace kit, surrounded by CEB