Triloboat

TriloBoat Overview

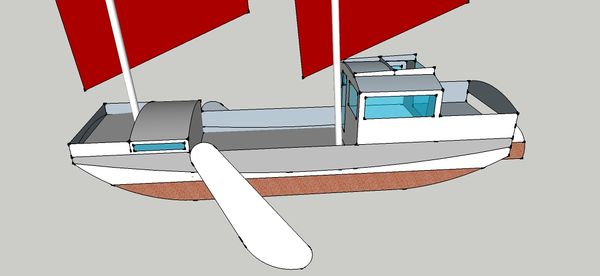

TriloBoats were designed by Dave Zeiger as a formula generated class of box barge (or scow) hulls based on construction from sheet materials.

The rules-of-thumb generate hundreds of instances in a wide array of sizes and functional layouts. Potential layouts include kayak, skiff, cargo, houseboat, cruisers and multihulls. They are compatible with sail and power.

The rules-of-thumb are selected to simplify construction for dramatic savings in time, energy, material and money.

With his partner, Anke Wagner, Dave has built three instances of TriloBoat, to date, including S/V SLACKTIDE, their home for the last three years. For further information, discussion, construction and sailing photos, please visit http://www.triloboats.com, and http://triloboats.blogspot.com.

TriloBoat Hull Rules-of-Thumb

- Hulls are simple, box barges - rectangular in plan and section views.

- Hulls are constructed from whole and simple-fraction multiples of rectangular, off-the-shelf, sheet materials.

- Hull beam is one sheet.

- Hull length is scalable, generally in multiples (or combinations) of full length sheets.

- Hull curves are limited to the ends (generally one quarter the LengthOfHull) , reducing lofting, layout, spiling, cutting, beveling and bending to bare minimums.

- Hull curves are separated by a dead-flat (planar section of bottom, generally one half the LengthOfHull).

- Hulls are self-rectifying and jig-less (consequences of these rules).

- All controlling numbers are rationalized (rounded), where possible, to maximize mnemonic retention, communication and accuracy.'

TriloBoat Superstructure Rules-of-Thumb

- Superstructures are constructed from whole and simple-fraction multiples of rectangular, off-the-shelf, sheet materials.

- Side decks are not used (flush decks maximize strength, simplify construction and assist ventilation).

- All decks are planar (sloped to drain), pitched or section-of-cylinder (simple layout and construction).

- Where section-of-cylinder decks are used, upper hull or superstructure are canted inboard to provide slack for a single sheet span of desired crown.

- All controlling numbers are rationalized (rounded), where possible, to maximize mnemonic retention, communication and accuracy.

TriloBoat Trade-Offs

- As one cuts away from the original prism (the rectangular slab formed by length x beam x draft), one reduces interior volume and displacement while reducing resistance through the water.

- High end curves meet waves better, but reduce flat-water speed, displacement and buoyancy, and interior volume.

- Every partial sheet generates lofting, cut-out and waste, but increase options. Simple fractions of sheets yielding round numbers (1, 1/2, 1/3, 1/4, 1/6, 1/8) generate less waste, and make for simple layout. Consider design for whole sheets where possible, and larger fractions where not.

- Curves take time, but reduce hull resistance, and in the superstructure shed water, add headroom and aesthetics