Triloboat

| Open Source Boat / TriloBoat |

|

|---|---|

| Home | Research & Development | Build It | User's Manual | Community Feedback |

TriloBoat Overview

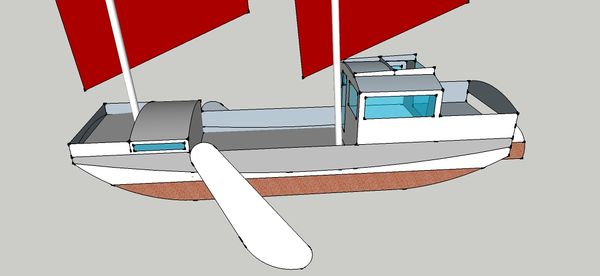

TriloBoats were designed by myself (Dave Zeiger) as a formula generated class of box barge (or scow) hulls based on construction from sheet materials.

The rules-of-thumb generate hundreds of instances in a wide array of sizes and functional layouts. Potential layouts include kayak, skiff, cargo carrier, landing craft, tug, ferry, houseboat, cruiser and multihull. They are compatible with sail and power. Appropriately designed, built and handled, TriloBoats are seaworthy across a wide range of conditions.

The rules-of-thumb are selected to simplify construction for dramatic savings in time, energy, material and money. This allows general construction by persons with very modest skills, with minimal resources and infrastructure.

I offer the TriloBoat concept as a candidate (subject to open source development) for Open Source Boat and Boat.

My partner, Anke Wagner, and I have built three instances of TriloBoat, to date, including S/V SLACKTIDE, our home for the last three years. For further information, discussion, construction and sailing photos, please visit http://www.triloboats.com, and http://triloboats.blogspot.com.

Detailed Description

The following is the TriloBoat Design Formula, expressed as rules-of-thumb and guidelines. Taken together, they generate a class of box barge hulls. By converting generalities to specifics within these guidelines, produces one instance among thousands of possibilities.

Note that these rules develop design lines, only. Construction details are dependent on materials and methods used. Appropriate marine construction standards should be followed in the fabrication and assembly process.

TriloBoat Hull Rules-of-Thumb

- Hulls are simple, box barges - rectangular in plan and section views.

- Hulls are constructed from whole and simple-fraction multiples of rectangular, off-the-shelf, sheet materials. Where possible, straight-line cuts that parallel one edge are preferred.

- Hull beam is one sheet.

- Hull length is scalable, generally in multiples (or combinations) of full length sheets.

- Hull curves are limited to the bottom ends (generally one quarter the LengthOfHull each, curved in profile view) , reducing lofting, layout, spiling, cutting, beveling and bending to bare minimums.

- Hull curves are separated by a bottom dead-flat (planar section of bottom, generally one half the LengthOfHull).

- Hulls are jigless, and self-rectifying (consequence of these rules).

- All controlling numbers are rationalized (rounded), where possible, to maximize mnemonic retention, communication and accuracy.

TriloBoat Superstructure Rules-of-Thumb

- Superstructures are constructed from whole and simple-fraction multiples of rectangular, off-the-shelf, sheet materials. Where possible, straight-line cuts that parallel one edge are preferred.

- Side decks are not used (flush decks maximize strength, simplify construction and assist ventilation).

- All decks are planar (sloped to drain), pitched or section-of-cylinder (simple layout and construction).

- Where section-of-cylinder decks are used, upper hull or superstructure are canted inboard to provide slack for a single sheet span of desired crown.

- All controlling numbers are rationalized (rounded), where possible, to maximize mnemonic retention, communication and accuracy.

TriloBoat Trade-Offs (Opposing Values)

- As one cuts away from the original prism (the rectangular slab formed by length x beam x draft), one improves efficiency through the water (by reducing drag), but reduces interior volume and displacement.

- Narrow-for-length is faster through the water. Wide-for-length is slower, but more commodious and hauls more cargo for its length. I shoot for a length to beam ratio of 4:1, and compromise away in either direction, as needed.

- High end curves meet waves better, but reduce flat-water speed, displacement/buoyancy and interior volume.

- Every partial sheet generates lofting, cut-out and waste, but increases options. Simple fractions of sheets yielding round numbers (1, 1/2, 1/3, 1/4, 1/6, 1/8) generate less waste, and make for simple layout. Consider design for whole sheets where possible, and larger fractions where not.

- Curves take time, but add rigidity and reduce hull resistance, and in the superstructure shed water, add headroom and aesthetics. Consider using them sparingly where their benefits outweigh costs.

TriloBoat Suggested Features

- Hull Divisions - 1/4 LengthOverAll as bow curve, 1/2 LengthOverAll as dead-flat (no bottom curve in profile view), and 1/4 LengthOverAll as aft curve. This allows easy end-curves while generating fully rectilinear mid-ships (simplifying construction of the interior and enabling modular furnishings), and allows easy blocking and transport by flat-bed.

- Locate a bulkhead at the division between dead-flat and end curve to simplify bending the bottom planking. Other bulkheads may be recommended along the hull length, depending on length and use.

- Box girder furnishings in the interior do much to stiffen the hull, and particularly the bottom.

- Plywood sheet construction with dimensional lumber framing (glued and nailed) is the fastest wood construction method. Sawn chine logs (from wide planks) at bow and stern are faster than bending, and require no steaming.

- External appendages (e.g., rudder, off-centerboards, skegs) avoid complicated and hull-weakening housings, wells and trunks. Much easier to dismount, inspect, maintain, modify and repurpose.

- Junk Rig - Easy to build, maintain and operate with short-handed crews. Low stress and fail safer. Minimal standing rigging. Flat cut sails require only rudimentary lofting and design. May use GVCS bioplastic fabric.

Notes

- All 'rules' may be altered or ignored by end-users. Each deviation, however, costs in time, material and efficiency. End-users are advised to consider cost/benefit returns for each departure.

- The relation between end curves and dead-flat is determined by use. One extreme, no end curves and all dead-flat, produces a dock-like hull. The other extreme, all curve and no dead-flat produces a constant 'rockered' bottom (easiest to move through water, but requires more time to build, generates more waste and reduces displacement and interior volume.

- The height of end curves is determined by intended use. High end curves clear more waves, especially at the bow, and are suitable for sailing hulls (which heel) or any hulls intended for use in unprotected waters. Lower end curves increase buoyancy and interior volume, and may be suitable for protected waters. A low or flat curve aft is consistent with planing hulls. There's a bit more to this that needs to be developed as an info module.

- Imperial System is recommended, unfortunately, unless using metric dimensioned sheets. This has to do with world standards for sheet dimensions generally being based on Imperial feet. Metric translations produce lengthy, non-mnemonic numbers which lead to miscommunication and error.

- The feet-inches-eighths system (a common standard in boat-building) helps simplify Imperial.

- Plywood sheets were the original inspiration, but the method is adaptable to any sheet material with maritime properties, such as steel and aluminum. Ply sheets are readily available in 4 x 8, 10, 12, 16 and 20 foot lengths (easy beam choices), though 4x8ft sheets are standard and the most economical. We've found select, AC grade to be sufficient.

- Consider composite sheet construction incorporating closed cell, insulating foam for vessels intended as Housing. SIP (Structural Insulated Panel) technologies are easily adaptable to Triloboat construction, and are recommended where insulation is desired.

Product Ecology

From

A TriloBoat is assembled from sheet materials which include wood, wood composites, (bio)plastic composites, steel or aluminum. Each material may involve a different toolset, and can benefit from production by tools from the GVCS.

Wood based construction might thus involve the Dimensional Sawmill. Metal based construction might involve Open Source Welder and Metal Roller. Composite contruction might involve the Bioplastic Extruder and/or Chipper. The Plasma Cutter or Laser Cutter might be involved in fleet construction.

Uses

Hardware, propulsion electronics, gear, outfit and accessories vary from extremely simple/minimal to highly advanced, and may use one to several tools from the GVCS.

For example, a pure sailing vessel need use no further tools from the GVCS.

In contrast, a landing-craft layout might arrange propulsion using the Heat Exchanger to power the Modern Steam Engine to turn a prop on the Universal Rotor. Hydraulic Motors might be used for propulsion, an anchor winch, various PTO (Power Take Off) tasks, or a modified Backhoe as a loading crane. The Nickle-Iron Battery to power shipboard electronics. A LifeTrac III might be carried to enhance longshoring capabilities. If steel, it might carry the Welder as part of its essential gear.

Creates

Transportation and/or Housing.

Enables

The Truck and Car are enabled, in the sense that their range is extended to isolated road systems which are accessible by water.

In a similar sense, the entire GVCS is potentially able to become mobile, allowing the sharing of tools or tool ecologies among communities close to water. The Truck has some capability for this, but is limited by the need for roads and has a relatively small, energy expensive payload.

Status

The TriloBoat Design Formula is fully developed, many instances have been designed, and several vessels built and more or less intensively field tested.

TriloBoat Concept Development

To be completed:

- TriloBoat's adaptation to the OSE platform and standards.

- Designation and cross-linking as Open Source Boat and/or Boat?

- Exposure to Open Source Development?

TriloBoat User Manual

To be developed:

- Guidelines for Adaptation to particular purposes and needs.

- Guidelines for Scantlings for various material suites and construction methods.

- Guidelines for Construction Methods and Techniques for various material suites.

- Guidelines for Sail Rig options and design.

- Guidelines for Power Propulsion options and design.

- Guidelines for GVCS and other tool ecologies.

- Open Portfolio of Gear and Outfit options.

Bill of Materials and Manufacturing Instructions

Yet to be developed is an Open Portfolio of Plans for representative Instances, each meeting a general configuration of [Boat], but focused on a particular use (e.g., Landing Craft).

Each Plan would be developed from the above as per GVCS usual, once the rules generating them have stabilized in the OSD process. In effect, the TriloBoat rules and guidelines jumpstart the research and development required for each Plan.

Each Plan would be comprised of a Bill of Materials and Manufacturing Instructions for a scalable product, in the normal, GVCS format.

Unlike other tools in the GVCS, the Portfolio will contain several [OSBoats], and remain Open (may be added to as new products are developed (e.g., landing-craft, cargo carrier, tug, etc.).

Associated Tasks

The following, associated materials are presently available in fully adequate form external to OSE, but may eventually be brought into OS development?

- Safety Standards for materials and methods used.

- Marine Training materials for end-users.