Triloboat

| Open_Source_Boat / TriloBoat |

|

|---|---|

| Home | Research & Development | Build It | User's Manual | Community Feedback |

Template:Open Source Boat Research and Development

TriloBoat Overview

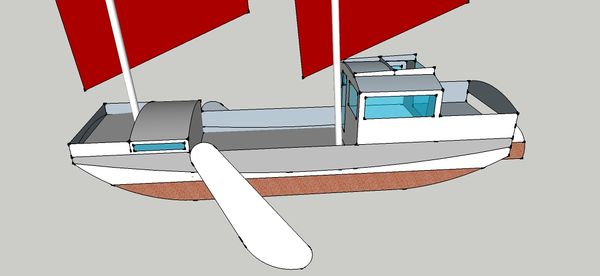

TriloBoats were designed by Dave Zeiger as a formula generated class of box barge (or scow) hulls based on construction from sheet materials.

The rules-of-thumb generate hundreds of instances in a wide array of sizes and functional layouts. Potential layouts include kayak, skiff, cargo carrier, tug, ferry, houseboat, cruiser and multihull. They are compatible with sail and power.

The rules-of-thumb are selected to simplify construction for dramatic savings in time, energy, material and money.

Triloboats are being offered as a starting point for the Open Source Boat (OSBoat)[1].

With his partner, Anke Wagner, Dave has built three instances of TriloBoat, to date, including S/V SLACKTIDE, their home for the last three years. For further information, discussion, construction and sailing photos, please visit http://www.triloboats.com, and http://triloboats.blogspot.com.

TriloBoat Hull Rules-of-Thumb

- Hulls are simple, box barges - rectangular in plan and section views.

- Hulls are constructed from whole and simple-fraction multiples of rectangular, off-the-shelf, sheet materials.

- Hull beam is one sheet.

- Hull length is scalable, generally in multiples (or combinations) of full length sheets.

- Hull curves are limited to the bottom ends (generally one quarter the LengthOfHull, curved in profile view) , reducing lofting, layout, spiling, cutting, beveling and bending to bare minimums.

- Hull curves are separated by a bottom dead-flat (planar section of bottom, generally one half the LengthOfHull).

- Hulls are self-rectifying and jig-less (consequences of these rules).

- All controlling numbers are rationalized (rounded), where possible, to maximize mnemonic retention, communication and accuracy.

TriloBoat Superstructure Rules-of-Thumb

- Superstructures are constructed from whole and simple-fraction multiples of rectangular, off-the-shelf, sheet materials.

- Side decks are not used (flush decks maximize strength, simplify construction and assist ventilation).

- All decks are planar (sloped to drain), pitched or section-of-cylinder (simple layout and construction).

- Where section-of-cylinder decks are used, upper hull or superstructure are canted inboard to provide slack for a single sheet span of desired crown.

- All controlling numbers are rationalized (rounded), where possible, to maximize mnemonic retention, communication and accuracy.

TriloBoat Trade-Offs (Opposing Values)

- As one cuts away from the original prism (the rectangular slab formed by length x beam x draft), one improves efficiency through the water (by reducing drag), but reduces interior volume and displacement.

- Narrow-for-length is faster through the water. Wide-for-length is slower, but more commodious and hauls more cargo for its length. I shoot for a length to beam ratio of 4:1, and compromise away in either direction, as needed.

- High end curves meet waves better, but reduce flat-water speed, displacement/buoyancy and interior volume.

- Every partial sheet generates lofting, cut-out and waste, but increases options. Simple fractions of sheets yielding round numbers (1, 1/2, 1/3, 1/4, 1/6, 1/8) generate less waste, and make for simple layout. Consider design for whole sheets where possible, and larger fractions where not.

- Curves take time, but add rigidity and reduce hull resistance, and in the superstructure shed water, add headroom and aesthetics. Consider using them sparingly where their benefits outweigh costs.

TriloBoat Suggested Features

- Hull Divisions - 1/4 LengthOverAll as bow curve, 1/2 LengthOverAll as dead-flat (no bottom curve in profile view), and 1/4 LengthOverAll as aft curve. This allows easy end-curves while generating fully rectilinear mid-ships (simplifying construction of the interior and enabling modular furnishings), and allows easy blocking and transport by flat-bed.

- Locate a bulkhead at the division between dead-flat and end curve to simplify bending the bottom planking. Other bulkheads may be recommended along the hull length, depending on length and use.

- Box girder furnishings in the interior do much to stiffen the hull, and particularly the bottom.

- Plywood sheet construction with dimensional lumber framing (glued and nailed) is the fastest wood construction method. Sawn chine logs (from wide planks) at bow and stern are faster than bending, and require no steaming.

- External appendages (e.g., rudder, off-centerboards, skegs). This avoids complicated and weakening housings, wells and trunks. Much easier to dismount, inspect, maintain, modify and repurpose.

- Junk Rig - Easy to build, maintain and operate with short-handed crews. Low stress and fail safer. Minimal standing rigging. Flat cut sails require only rudimentary lofting and design. May use GVCS bioplastic fabric.

Notes

- All 'rules' may be altered or ignored by end-users. Each deviation, however, costs in time, material and efficiency. End-users are advised to consider cost/benefit returns for each departure.

- The relation between end curves and dead-flat is determined by use. One extreme, no end curves and all dead-flat, produces a dock-like hull. The other extreme, no all curve and no dead-flat produces a constant 'rockered' bottom (easiest to move through water, but requires more time to build, generates more waste and reduces displacement and interior volume.

- The height of end curves is determined by use. High ends clear more waves, especially at the bow, and are suitable to sailing or exposed water hulls. Lower heights increase buoyancy and interior volume, and can be used in protected waters. A low or flat curve aft is consistent with planing hulls. There's a bit more to this that needs to be developed as an info module.

- Imperial System is recommended, unfortunately, unless using metric dimensioned sheets. This has to do with world standards for sheet dimensions generally being based on Imperial feet. Metric translations produce lengthy, non-mnemonic numbers which lead to miscommunication and error.

- The feet-inches-eighths system (a common standard in boat-building) helps simplify Imperial.

- Plywood sheets were the original inspiration, but the method is adaptable to any sheet material with maritime properties, such as steel and aluminum. Ply sheets are readily available in 4 x 8, 10, 12, 16 and 20 foot lengths (easy beam choices), though 4x8ft sheets are standard and the most economical. We've found select, AC grade to be sufficient.

- This rule-set should be supplemented by additional information regarding selecting scantlings, height of end curves, draft considerations, and various construction methods and options. As watercraft, they are subject to a much wider skillset for their safe operation.

- Rig and lateral resistance information packs need to be developed, as well as integration with GVCS PowerCubes and related propulsion.