Equipment/Lulzbot a0 101

| Lulzbot A0-101 | |

|---|---|

| |

| Sub-category | CNC |

| Status | Good working order |

| Last updated | {{#show: Equipment/Lulzbot a0 101 | ?Modification date}} |

| Last updated by | {{#show: Equipment/Lulzbot a0 101 | ?Last editor is}} |

| Consumables | Printer filament |

| Training requirement | Yes |

| Training link | 3dprinter_training |

| Owner | OSE |

| Origin | Donation |

| Location | Ground floor, classroom, under desk |

| Maintainers |

Ian Lewis {{#set:name=Lulzbot A0-101}} {{#set:image=AO-101-1600.jpg}} {{#set:status=Good working order}} {{#set:subcat=CNC}} {{#set:location=Ground floor, classroom, under desk}} {{#set:owner=OSE}} {{#set:maintainers=Ian Lewis}} {{#set:reqtraining=Yes}} {{#set:acnode=}} |

Description

It is a A0 101D printer.

Specification & documentation

Consumables

If using any consumables, link here to recommended providers or current pledges to purchase.

Filament options (3.0mm)

- ABS (lego brick plastic - prints at 190-230 DegC, requires heated bed at 100-110 DegC)

- PLA (biodegradable , based on food starch - prints at 185-190 DegC, optional heated bed, not hotter than 60 DegC)

- There are other 'specialist' filament, like wood effect, stone effect, nylon (can be coloured by clothes dye), etc

Loading Filament Excerpt from the manual describing loading filament

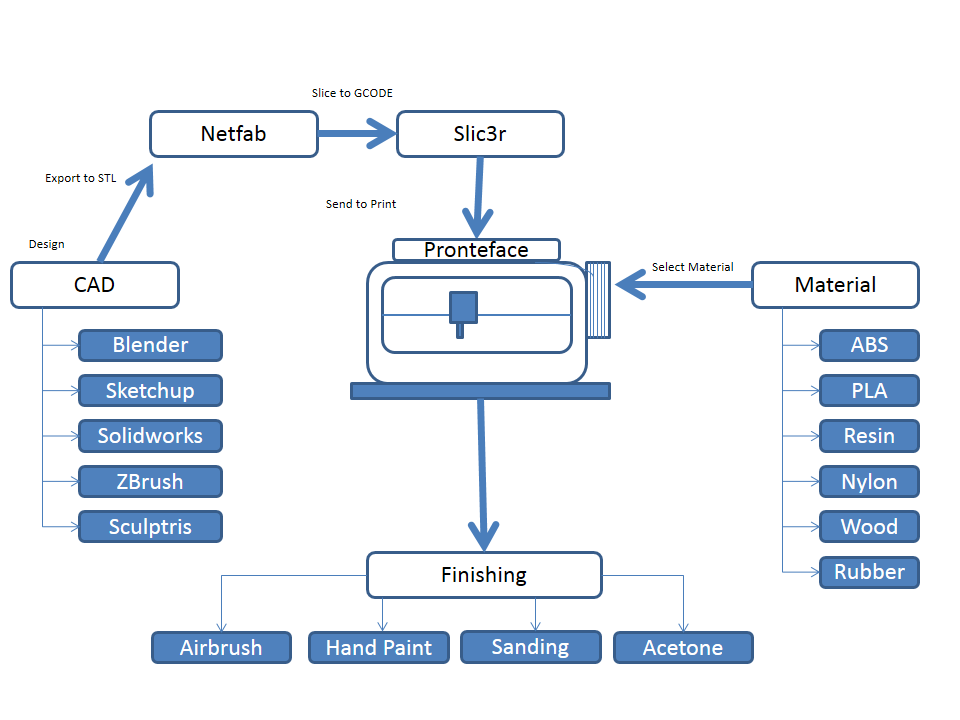

3D printing process

Software (Free or Open Source)

- Sketchup Design, go to the Warehouse for the Export STL add-in

- Blender Design, quite complicated

- OpenSCAD The Programmers Solid 3D CAD Modeller. You'll love it or hate it.

- Netfabb Basic Repairing and orienting STL for Slicing

- Meshmixer A new mesh working tool, with support generation

- Slic3r Slicing STL files into GCODE for printing

- Pronteface Connecting the Computer to the printer and PRINTING!

- Octoprint remote control of your printer

Training & instruction

Training IS REQUIRED and is being carried out voluntarily by the current maintainer, more info on the separate training page

Please do not use the printer if you have not been trained, even if you think you know how to use it.

Links

AO-101-User_Manual local copy File:AO-101-User Manual.pdf

There are a number of files provided by Lulzbot with predefined settings. setting 1 is for 0.3mm layers with a 60% infill. setting 2 is for 0.4mm layers and 80% infill.

I would stick with the config in the training section until we conplete calibration.

- Cost of 3D printing See what you design would cost if you printed it professionally

- GCODE cost analyser Use 3mm ABS as the standard filament setting, load your file and see the cost

Cost for Printing

Using the above tool, calculate the cost of the print, add £1.20 per hour of printing, place it in the box provided and mark it on the Log Book

Training

The config file for Slic3r provided during training is here

Modification

added a fan to improve printing for small areas. Note that using the fan will stop the print from sticking properly with ABS. Under Filament Settings in Slic3r, under Cooling, use the "Disable fan for the first:" to something over 20 layers (depending on number of print layers).

The original fan mount breaks very easily. Additionally, it doubles as the clamp for the X axis belt and has no teeth so the belt comes loose easily. The clamp/mount has been replaced: