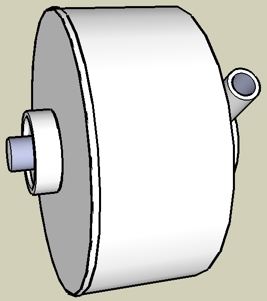

Turbine Fabrication

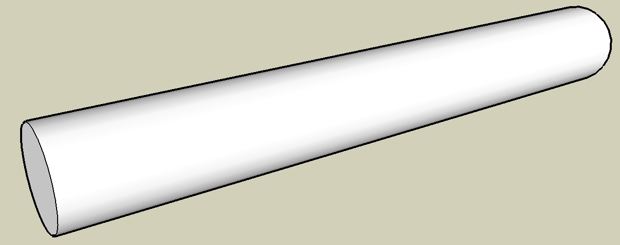

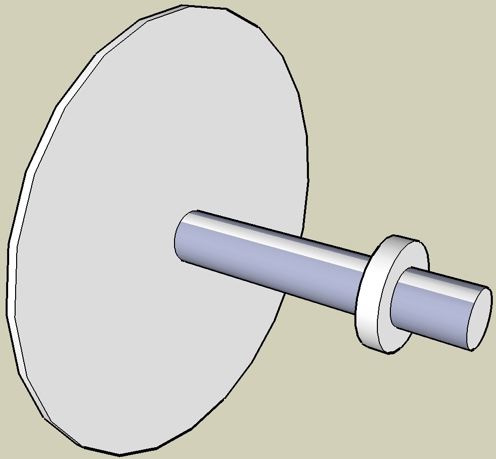

The turbine fabrication procedure starts with a 1.5” shaft. Sourcing: part # 8920K312 at McMaster Carr. Cost: $15

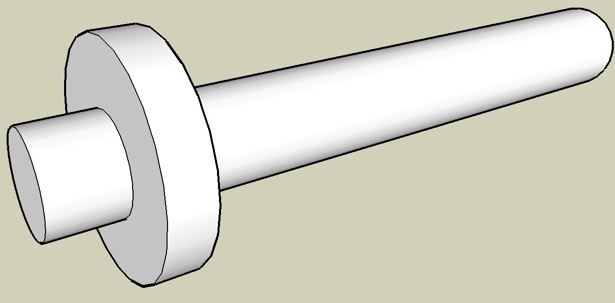

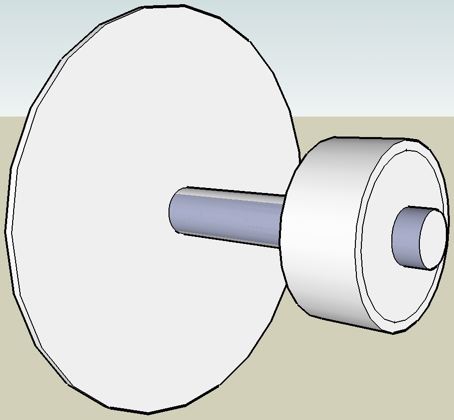

Find a bearing to fit the shaft. Sourcing: ____ . Cost:

Also, find a spacer, with 1.5 inch ID and 1/8” wall. It is 1/4” long + width of seal (see seal design drawing). Sourcing: ______ Cost:

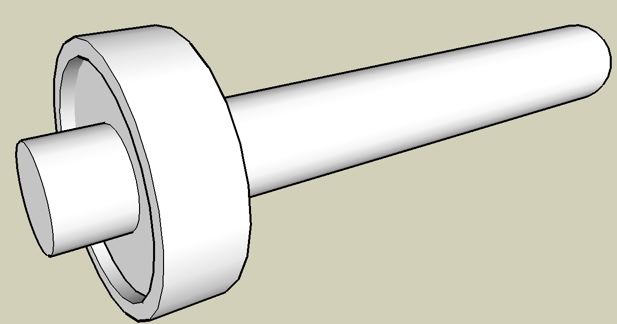

Also, find a seal to match the spacer. 1.75” ID and 3” OD.

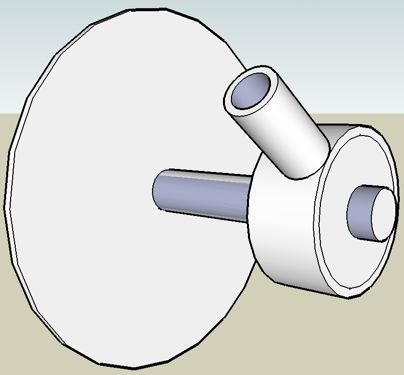

Find end pipe section to house the bearing, seal, and spacer. Sourcing: ____ . Cost:

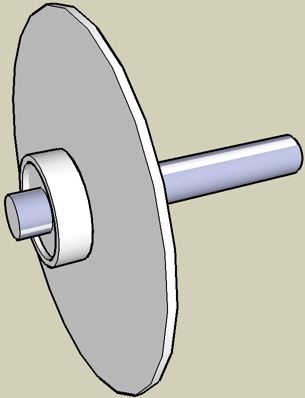

Find 5/16” plate steel for end side of turbine. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

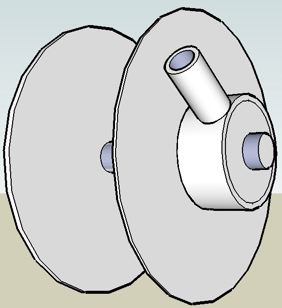

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost: File:Turbine fab10.jpg