RotoKnitic v19.01

Jump to navigation

Jump to search

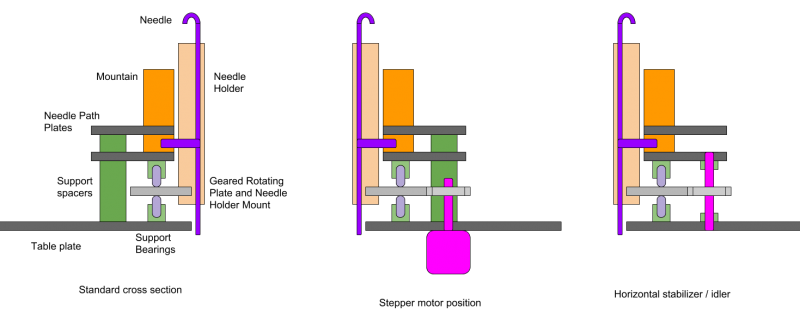

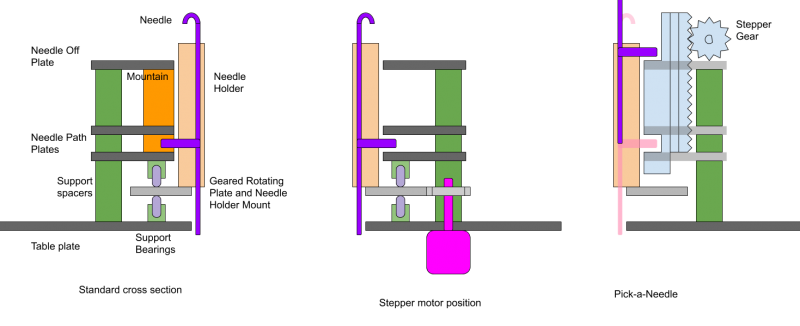

Using same parts and materials from OSE CircularKnitic v18.03, but switch mounting plates so that the mountain is stationary.

- requires spinning spool for fabric output

- allows for more multiple mountains and input threads

Design

- Needles will rotate in the needle holder

- https://github.com/OpenSourceEcology/circular_knitic_pick-a-needle

Concept

Standard

Pick-a-Needle

Goals

- change direction

- sock heels

Needle Accomidation

- pick-a-needle, optionally raise needles to an inactive postion

- Test laser cut needles, printed latch?

- Test 3D printed needles

Fabric Spool

- Apply constant tension on fabric

- Roll onto spool for easy handling and storage

Provisional BOM

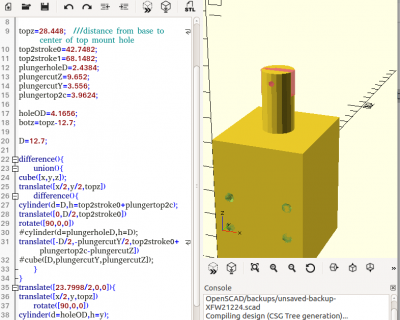

Part SCAD Code

Variable Profiles

CKvarsProfile_36in_201906.scad

/////////////////// USER SETTINGS /////////////////// ///////////// // USING THIS FILE: // choose desired settings below // rename and save this file into the "SCAD" folder // for example CKvarsProfile-Small2019.scad // then open the file named CKvars.scad in the "SCAD" folder // find the "include" commands at the begining of the file // change this information to the new file's name, then save // you can now open then render each part file with these settings ///////////// //File Notes - Large201903 // attempting to get near 45" 1100mm fabric width/circumference // ///////////// // DIMENSIONS //number of "p2" needle guides around circle //Jan2019 //small UPp2number=30; //12 //36 ///36 //12 //8 //number of needles mounted on each "p2" part UPp2needles=5; //5 //10 ///5 //5 //7 //number of "p3" parts around circle UPp3number=10; //4 //18 ///4 //4 //2 //number of "p4" parts around circle UPp4number=10; //4 //18 ///4 //4 //2 //distance from the inside face of one needle to the next UPneedle2needle=9.7; //default=14.35615 //try 8.414 //13.5334 //9.25 //mountain settings UPpMgrooveturnR=14; //radius of upper curved path in groove //14 //10 UPpMgrooveturnR2=7; //radius of lower curved path in groove //7 UPpMp3X=2.5; //length of lower plateu of groove //2.5 //2 UPpMp7X=3; //half of length of top plateu of groove //3 //2 UPnumberMountain=6; ///////////// // MATERIALS //thread diameter UPthreadD=2.5; //number of stepper motors driving the geared plate UPc1steppersnumber=UPnumberMountain; //laser cut part thickness UPupper_surfaceH=5; //thickness of upper rotating plate ///5 //6.35= 1/4"inch UPbottom_surface_motor_gearsH=5; //thickness of geared rotating plate UPtable_surface=10; //thickness of plate of main table UPtable_support=12.7; //thickness of support board below table surface //width of wood used to support table around the edges UPwoodbeamW=25.4; //table leg wood beam width 1.0 inch UPwoodbeamScrewOD=6; // M6 screw hole into wood beam //thread feeder option UPTF=1; // 0=none 1=angle iron 2=makerbeam10mm //angle iron option dimensions UPaaX=12.7; //width //12.7 = 1/2in UPaaT=1.5875; //thickness //1.5875 = 1/16in ///////////////////////////////////////////////

CKvars.scad

Needles

2D Laser Cut Parts

3D Printed Parts

p4 "yarn holder"

include <CKvars.scad>;

CKp4();

module CKp4(){

rez=p2number*p2needles*2;

$fn=rez; //defines resolution of circles.

translate([p4baseOD/2,0,0]){

difference(){

union(){

cylinder(h=p4baseH,d=p4baseOD-(p4basegapW*2)-((p4baseW-p4basegapW)/2*2));

//ramps

for(i=[1:p2needles*(p2number/p4number)]){

rotate([0,0,(360/p2number/p2needles)-(360/p2number/p2needles*i)-(((360/p2number/p2needles))/2)]){

difference(){

minkowski(){

union(){

translate([-p4baseOD/2+p4rampfromOD,p4rampWm/2,p4rampH+p4baseH-(p4rampC1/2)])

rotate([90,0,0])

cylinder(h=p4rampWm,d=p4rampC1);

intersection(){

translate([-10,0,3.82])

translate([-p4baseOD/2+p4rampfromOD,p4rampWm/2,p4rampH+p4baseH-(p4rampC2/2)])

rotate([90,0,0])

cylinder(h=p4rampWm,d=p4rampC2);

translate([-7,0,-2.86/2])

translate([-p4baseOD/2+p4rampfromOD,p4rampWm/2,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

}

}//end union

difference(){

translate([-p4rampMinkD/2,0,0])

cylinder(d=p4rampMinkD,h=0.01, $fn=36);

translate([-p4rampMinkD,0,-0.01])

cube([p4rampMinkD,p4rampMinkD,0.02], center=true);

} //end diff

} //end mink

translate([-p4rampC2/2,0,0])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2+1],center=true);

translate([0,0,0])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4baseH-(p4rampC2/2)-0.1])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([0,-p4clawW/2,0])

translate([-(p4baseID/2)-p4rampfromID,0,p4baseH])

cube([(p4baseID/2)+p4rampfromID,p4clawW,p4rampoverhangH]);

translate([-7,0,0])

translate([-p4baseOD/2+p4rampfromOD,(p4rampW/2)+(p4rampC2/2)-0.01,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([-7,0,0])

translate([-p4baseOD/2+p4rampfromOD,-(p4rampW/2)-(p4rampC2/2)+0.01,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

}//end ramps difference

} //end for rotate

} //end for

//claws

for(i=[1:p2needles*(p2number/p4number)]){

rotate([0,0,(360/p2number/p2needles)-(360/p2number/p2needles*i)-(((360/p2number/p2needles))/2)]){

hull(){

translate([-p4baseOD/2,-p4clawW/2,0])

#cube([(p4baseOD-p4baseID)/2,p4clawW,p4basegapH]);

translate([-p4baseOD/2,-((p4rampW+p4clawWslanttop)/2),p4baseH-0.1])

#cube([(p4baseOD-p4baseID)/2,p4rampW+p4clawWslanttop,0.1]);

} //end hull

}

}//end for

} //end main union

cylinder(h=p4baseH,d=p4baseID);

//simiple chamfer of inside corner

translate([0,0,p4baseH-0.5])

cylinder(h=0.5,d1=p4baseID+0.5,d2=p4baseID+1.9);

translate([0,0,p4baseH-0.5-0.5])

cylinder(h=0.5,d1=p4baseID,d2=p4baseID+0.5);

translate([-p4baseOD/2,-p4baseOD/2,0]){

cube([p4baseOD,p4baseOD/2,p4baseH]);

}

rotate([0,0,-360/p4number]){

translate([-p4baseOD/2,0,0])

cube([p4baseOD,p4baseOD/2,p4baseH]);

}

difference(){

cylinder(h=p4basegapH,d=p4basegapOD);

cylinder(h=p4basegapH,d=p4basegapID);

}

//bolt holes

for(i=[0:(p2number/p4number)-1]){

rotate([0,0,(-360/p2number/p2needles*0.5)+(i*-360/p2number)]){

if(p2p4type==1){

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

cylinder(d1=p2p4flatHD,d2=0,h=(p2p4flatHD/2)/tan(45),$fn=36);

translate([0,0,-(p2p4flatHD)/tan(45)])

cylinder(d1=p2p4flatHD*3,d2=p2p4flatHD,h=(p2p4flatHD)/tan(45),$fn=36);

cylinder(d=p2p4flatD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

if(p2p4type==0){

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

translate([0,0,-p2p4boltHH/2])

cylinder(d=p2p4boltHD,h=p2p4boltHH,$fn=36);

cylinder(d=p2p4boltD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

}

}

//second set

for(i=[0:(p2number/p3number)-1]){

rotate([0,0,-(360/p2number/p2needles*0.5)+(360/p2number/p2needles)+(i*-360/p2number)+(-360/p2number)]){

if(p2p4type==1){ // if flat socket

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

cylinder(d1=p2p4flatHD,d2=0,h=(p2p4flatHD/2)/tan(45),$fn=36);

translate([0,0,-(p2p4flatHD)/tan(45)])

cylinder(d1=p2p4flatHD*3,d2=p2p4flatHD,h=(p2p4flatHD)/tan(45),$fn=36);

cylinder(d=p2p4flatD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

if(p2p4type==0){ // if regular socket

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

translate([0,0,-p2p4boltHH/2])

cylinder(d=p2p4boltHD,h=p2p4boltHH,$fn=36);

cylinder(d=p2p4boltD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

} //end rotate

} //end for

//end mounting holes

//trim end

if(p4number>1){

rotate([0,0,-(360/(p4baseOD*PI/p4endtrim))])

mirror([1,1,0])

cube([p4baseOD/2,p4baseOD/2,p4rampH+p4baseH]);

}

} //end main difference

} //end main translate

} //end module

Parts

Pontiac Coil L-09

PCL90();

module PCL90(){

x=36.576;

y=41.402;

z=51.308;

topz=28.448; ///distance from base to center of top mount hole

top2stroke0=42.7482;

top2stroke1=68.1482;

plungerholeD=2.4384;

plungercutZ=9.652;

plungercutY=3.556;

plungertop2c=3.9624;

holeOD=4.1656;

botz=topz-12.7;

D=12.7;

difference(){

union(){

cube([x,y,z]);

translate([x/2,y/2,topz])

difference(){

cylinder(d=D,h=top2stroke0+plungertop2c);

translate([0,D/2,top2stroke0])

rotate([90,0,0])

#cylinder(d=plungerholeD,h=D);

translate([-D/2,-plungercutY/2,top2stroke0+plungertop2c-plungercutZ])

#cube([D,plungercutY,plungercutZ]);

}

}

translate([23.7998/2,0,0]){

translate([x/2,y,topz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

translate([x/2,y,botz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

}

translate([-23.7998/2,0,0]){

translate([x/2,y,topz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

translate([x/2,y,botz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

}

}//end main diff

}//end module

Full Assembly

BOM

TODO

- remove p8 plate connector under mountain

- put hole for makerbeam on plate below

- breakup tabletop plate into multiple pieces to make max size smaller

- could make all cut plates hexagons except for geared plate.

- could make geared a little larger if move support spacer to bridge stepper gear

- tweak outiside diameter values to remove p9

- change p9 to a simple p8 variant near steppers

- could just set p9 thickness to zero for now