Hemp Decorticator

A hemp decorticator is a machine that separates hemp stalks in to different materials that are used for a vast array of products;

· Bast fiber (for plastics including 3D printer filament, composite materials, textile, etc.)

· Hurd (for paper, hempcrete, insulation, fibre board, etc.)

· Green microfiber (beauty products, CBD, nutritional products, etc.)

Hemp seeds can also be used and turned in to food products, ink, paint, lubricant, etc.

Working principle

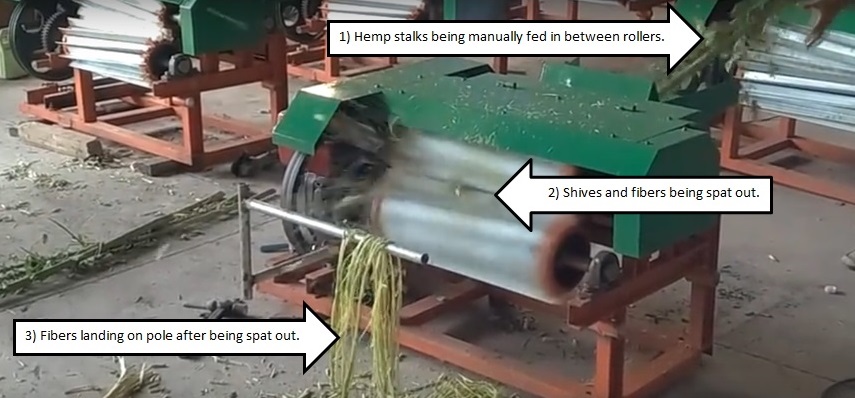

Several hemp stalks at a time, are fed into one end of the machine in between a pair of rollers.

The stalks are grinded in between the roller pair so that the soft exterior of the stalk, the bast fibers, are peeled off the hard, woody interior off the stalk which is crushed into smaller pieces called hurd or shives.

Both the hurd and the fibers will be spat out the other end of the decorticator from in between the rollers.

The hurd will land on the floor or in a container while the fibers can be “caught” by simply placing a pipe horizontally in front of the roller pair so that the fiber will hang from the pipe after being spat out.

The rollers are connected via a pulley and driven by a motor. They are held in place by bearings on their opposite end.

Other considerations

Design measures can be taken to reduce noise and dust.

Additional roller pairs can be added.

More advanced hemp decorticators can separate hemp stalks into a third material; green micro fibers which are mostly used for CBD products.