Bearing Selection

The selection of bearings is consists of the following steps which are described in further detail on this page;

1. Select bearing type suitable for load condition

2. Select bearing arrangement suitable for load condition

3. Dimension bearings

4. Select bearing housing design

Selection of bearing type

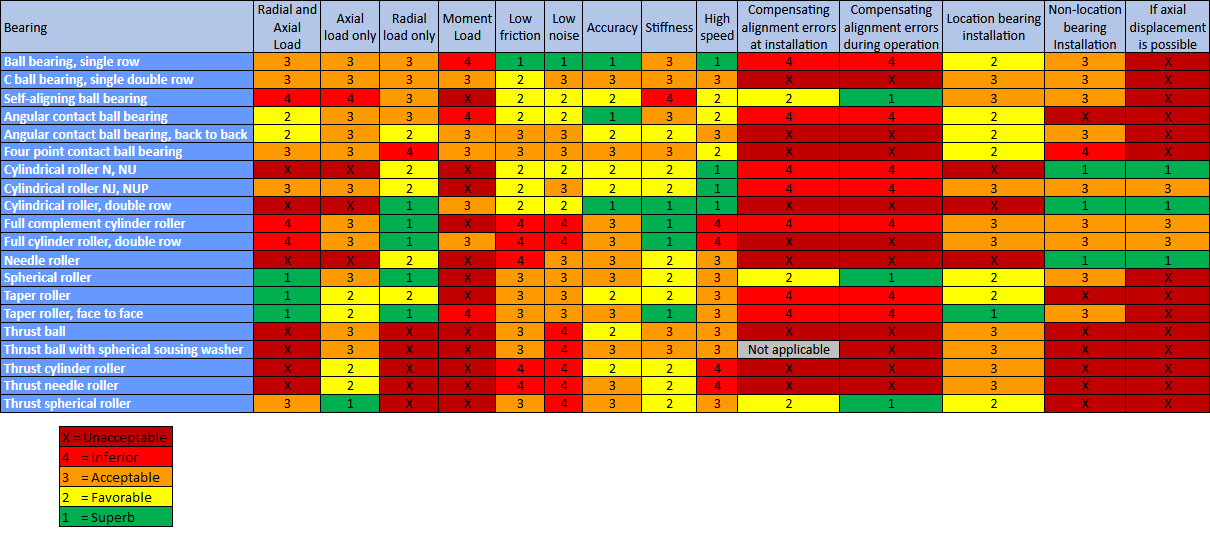

The table below shows level of suitability of different bearing types for different conditions.

This section is based on a table found in SKF handbooks and on the Engineers Edge website.

Selection of bearing arrangement

There are three basic bearing arrangements:

1. Face to face

2. Back to back

3. Tandem

These arrangements can also be combined.

Back-to-back arrangement

In a back-to-back arrangement, the load lines diverge along the bearing axis. Axial loads acting in both directions can be accommodated, but only by one bearing or bearing set in each direction. Bearings mounted back-to-back provide a relatively rigid bearing arrangement. The wide span between bearing effective centres makes this arrangement particularly well suited to support moment loads."

Face-to-face arrangement

In a face-to-face arrangement, the load lines converge along the bearing axis. Axial loads acting in both directions can be accommodated, but only by one bearing or bearing set in each direction. The shorter span between effective bearing centres makes face-to-face arrangements less suitable to support moment loads compared to bearings in a back-to-back arrangement."

Tandem arrangement

The use of a tandem arrangement provides increased axial and radial load carrying capacity compared to a single bearing. In a tandem arrangement, the load lines are parallel so that radial and axial loads are shared. The bearing set can only accommodate axial loads acting in one direction. If axial loads act in both directions, or if combined loads are present, additional bearing(s) adjusted against the tandem arrangement must be added."

Examples

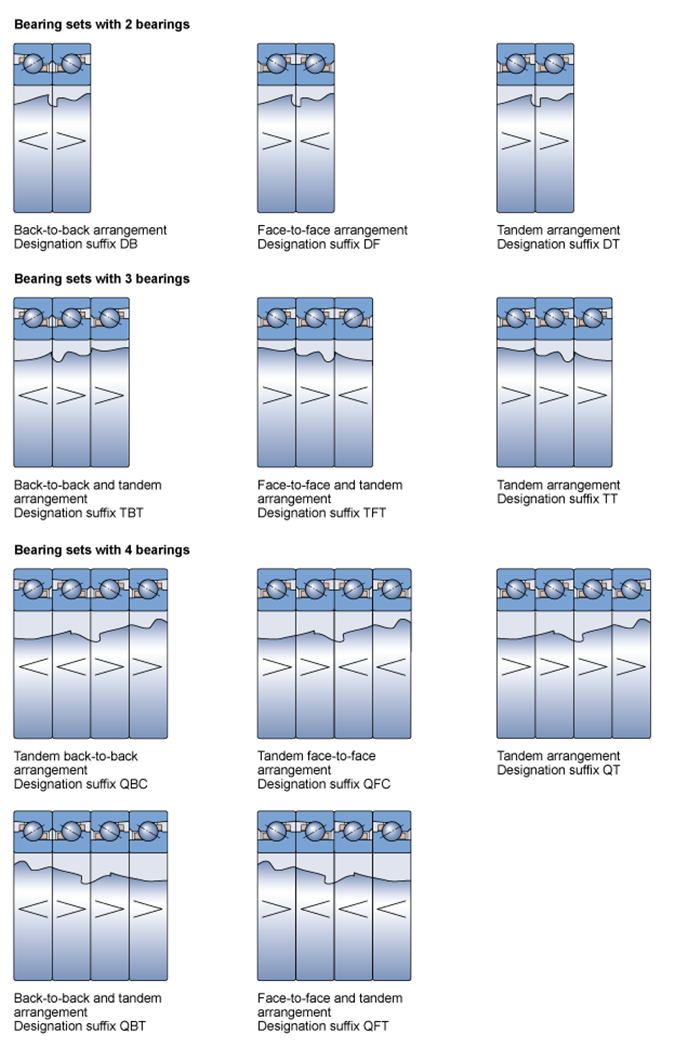

Universally matchable single direction bearings can be arranged in various ways depending on the stiffness and load requirements of the application. The possible arrangements are shown in the image, including the applicable designation suffixes for matched sets. If misalignment cannot be avoided between the bearing positions, face-to-face bearing arrangements are recommended. They are less sensitive to misalignment than back-to-back bearing arrangements. Combinations of tandem arrangements with back-to-back or face-to-face arrangements are usually selected to maximize the stiffness or load carrying capacity of a bearing set in a particular direction. This is the case, for example, when extended, preloaded, vertical or overhung screw drives must be supported."

This section is based on information listed on www.SKF.com and in SKF handbooks.

Dimensioning of bearings

This section describes the steps for dimensioning a bearing. The size of the bearing will depend on the load and the minimum lifetime you want for your bearing. The lifetime of a bearing is calculated using this formula:

L10h = (10^6 / 60n) * ((C/P)^p)

where

L10h = bearing lifetime in hours

n = revolutions per minute

C = dynamic load rating (this value is listed by the manufacturer or the designer)

P = Equivalent dynamic bearing load

p = a constant depending on bearing type.

( Nominal bearing lifetime is just L10 = (C/P)^p. It has a 90% reliability.)

1. Choose a minimum lifetime for your bearing

Decide how many operating hours you want the bearing to be functional for before it brakes.

2. Calculate Axial load (Fa) and Radial load (Fr)

Some load cases only have a radial load, some only have axial load and some have a combination of axial and radial load.

3. Determine the Equivalent dynamic bearing load (P)

Depending on the load case the formula for P will vary;

P = F

when the load is constant in magnitude and direction and acts radially on a radial bearing or axially and centrically on a thrust bearing.

P = Fa

for certain thrust bearings that can only accommodate pure axial loads, such as thrust ball bearings and cylindrical and needle roller thrust bearings, provided that the load acts centrically.

P = XFr + YFa

if a bearing is loaded with simultaneously acting radial load Fr and axial load Fa that are constant in magnitude and direction

where

P equivalent dynamic bearing load [kN]

Fr actual radial bearing load [kN]

Fa actual axial bearing load [kN]

X radial load factor for the bearing

Y axial load factor for the bearing.

P = Fr + Y Fa

for tapered roller bearings and spherical roller bearings.

P = Fr

for cylindrical roller bearings

where

P = equivalent dynamic bearing load [kN]

Y = axial load bearing facto.

4. Determine the value for p-constant

The value of the constant p will depend on the bearing type;

p = 3 for ball bearings

p = 1/3 for roller bearings

p = 4 for pure line contact

5. Determine the value for the Dynamic load rating C

The value for the Dynamic load rating (C) is listed by the manufacturer or the designer.

Select a bearing from a product catalog and note its C-value.

Input the C-value into the bearing lifetime formula along with the values for n, P, and p.

If this calculated lifetime (L10h) is lower than the desired lifetime, you need to try with another bearing with a higher C-value.

If the calculated lifetime is higher than the desired lifetime, you can select a bearing with a lower C-value. The calculated lifetime should be at least as high as the desired lifetime.