Bearing Selection

The instructions on this page are intended to guide the designer through the process of selecting bearings that are appropriate in type and size for its intended purpose and load condition.

The selection of bearings includes the following steps: (which are described in further detail on this page)

Step 1) Define load condition

Step 2) Select bearing type

Step 3) Select bearing arrangement

Step 4) Dimension bearing (includes link to OSE Bearing Calculator)

Step 5) Select bearing housing design

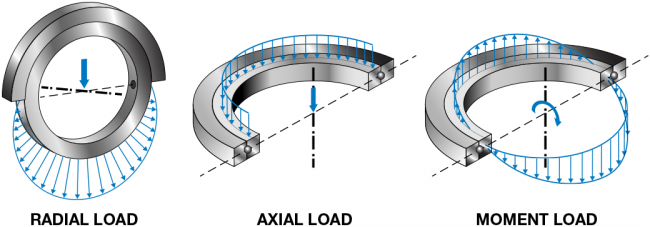

Step 1) Define load condition

Determine the direction of the forces that the bearing is exposed to. (The magnitude of the forces will be calculated in step 4.2)

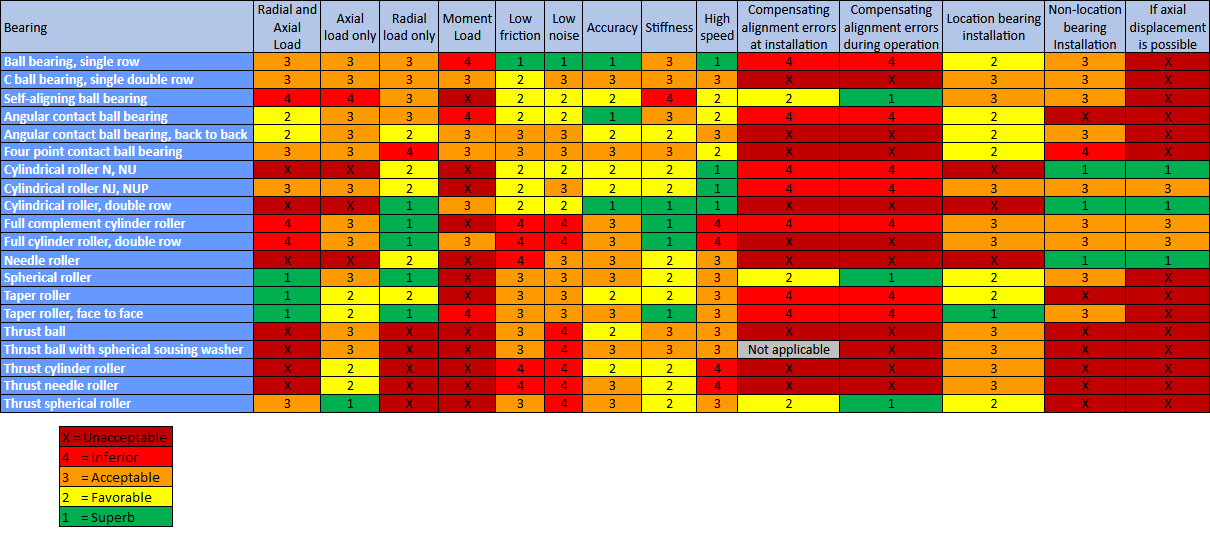

Step 2) Select bearing type

Use the table below to select a bearing type that is appropriate for the load condition along with other attributes of your application.

This section is based on a table found in SKF handbooks and on the Engineers Edge website.

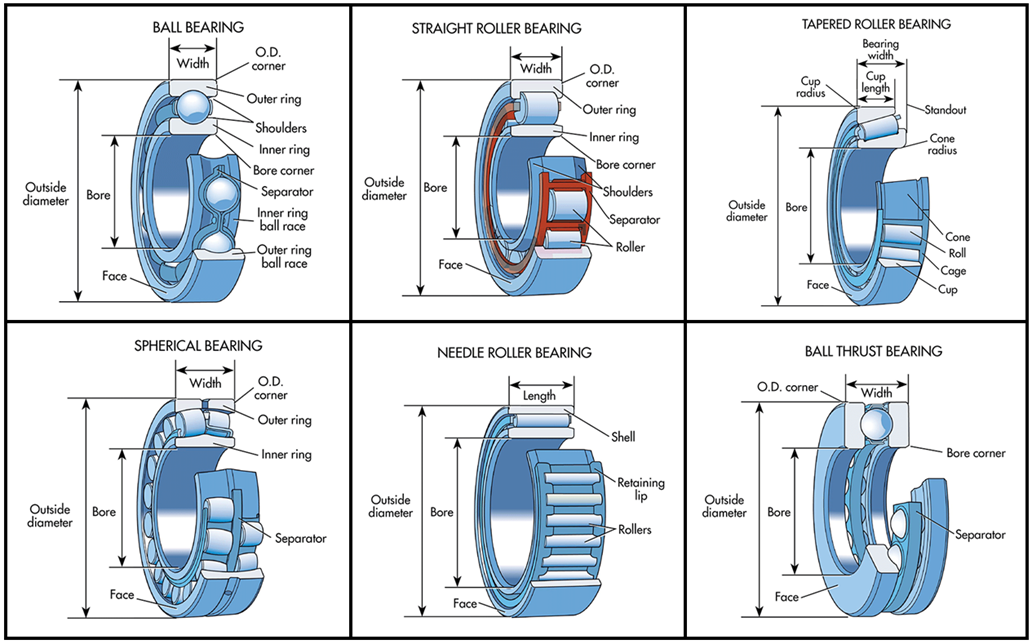

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings

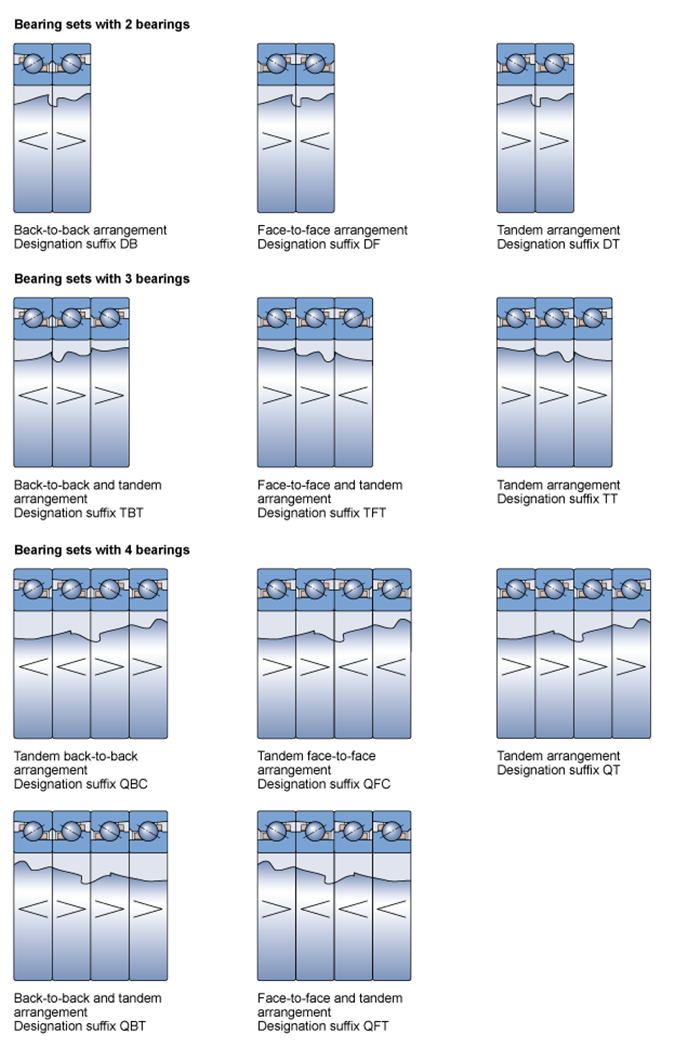

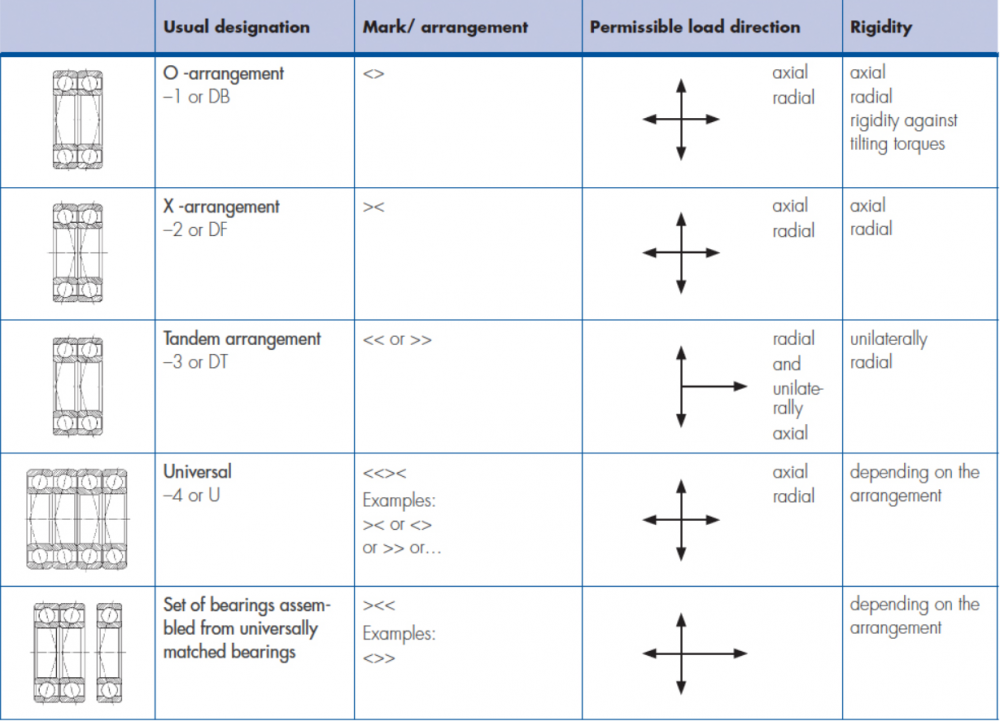

Step 3) Select bearing arrangement

More than one bearing can be used at each end of an axle. If so, their arrangement should be appropriate for the load condition. There are three basic bearing arrangements:

- Back to back

- Face to face

- Tandem

These arrangements can also be combined.

Back-to-back arrangement

In a back-to-back arrangement, the load lines diverge along the bearing axis. Axial loads acting in both directions can be accommodated, but only by one bearing or bearing set in each direction. Bearings mounted back-to-back provide a relatively rigid bearing arrangement. The wide span between bearing effective centres makes this arrangement particularly well suited to support moment loads.

Face-to-face arrangement

In a face-to-face arrangement, the load lines converge along the bearing axis. Axial loads acting in both directions can be accommodated, but only by one bearing or bearing set in each direction. The shorter span between effective bearing centres makes face-to-face arrangements less suitable to support moment loads compared to bearings in a back-to-back arrangement.

Tandem arrangement

The use of a tandem arrangement provides increased axial and radial load carrying capacity compared to a single bearing. In a tandem arrangement, the load lines are parallel so that radial and axial loads are shared. The bearing set can only accommodate axial loads acting in one direction. If axial loads act in both directions, or if combined loads are present, additional bearing(s) adjusted against the tandem arrangement must be added.

Examples

Universally matchable single direction bearings can be arranged in various ways depending on the stiffness and load requirements of the application. The possible arrangements are shown in the image, including the applicable designation suffixes for matched sets. If misalignment cannot be avoided between the bearing positions, face-to-face bearing arrangements are recommended. They are less sensitive to misalignment than back-to-back bearing arrangements. Combinations of tandem arrangements with back-to-back or face-to-face arrangements are usually selected to maximize the stiffness or load carrying capacity of a bearing set in a particular direction. This is the case, for example, when extended, preloaded, vertical or overhung screw drives must be supported.

This section is based on information listed on www.SKF.com and in SKF handbooks.

Step 4) Dimension bearing

This section describes the steps for dimensioning a bearing using the L10h-formula;

L10h = (10^6 / 60n) * ((C/P)^p)

The latest stable version of the Open Source Ecology Bearing dimensioning calculator is found here:

OSE Bearing dimensioning calculator

Dimensioning steps summary

4.1) Select desired value for L10h; how many hours you want your bearing to be operational.

4.2) Calculate Radial load (Fr) and/or Axial load (Fa) and/or Moment load (M)

4.3) Calculate the Equivalent dynamic bearing load (P)

4.4) Determine the value for the p-constant

4.5) Input C- and n-values of different bearings into L10h-formula until L10h-value matches desired L10h-value

4.1) Select desired value for L10h; how many hours you want your bearing to be operational

Bearings are dimensioned based on how long they are intended to last before failure due to material fatigue.

If you know the expected service life of your machine, for example 10 years, and want to avoid replacing the bearings during the machine's lifetime, you can select bearings that can be operational for 10 years = 8760 hours.

It is not uncommon for bearings to be operational for 8-12 years if maintained and greased properly.

To calculate a bearing's theoretical service life, we use the formula for calculating the so called L10 life. The same formula is used for both radial and linear bearings.

The L10 life is the number of revolutions or hours that 90% of identical bearings will last. (In other words, 10% of identical bearings in a given group are not expected to achieve the L10 life.)

4.2)Calculate Radial load (Fr) and/or Axial load (Fa) and/or Moment load (M)

Some load cases only have radial load, some only have axial load and some have a combination of axial and radial load.

A radial load is perpendicular to the axle. An axial load is parallel to the axle.

Let’s have a look at an example:

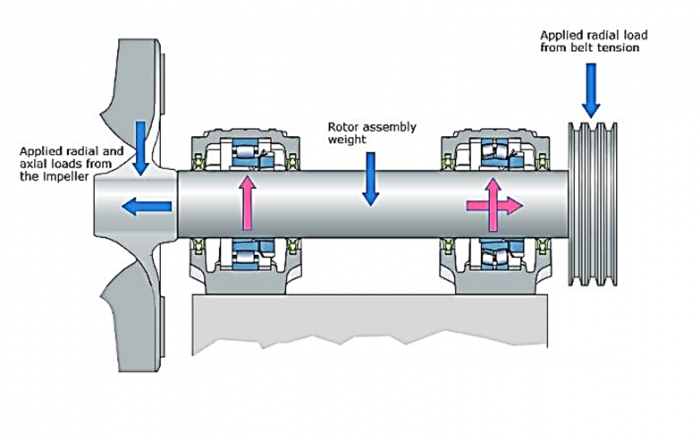

The image below shows an industrial fan made up of the following components:

- an impeller (on the left end of the axle)

- a belt pulley (on the right end of the axle)

- an axle

- a single row roller bearing (close to the impeller) in a pillow block bearing housing

- a spherical roller bearing (close to the belt pulley) in a pillow block bearing housing

These additional components are not shown in the image because they don’t directly create forces acting on the bearings:

- a motor

- a smaller belt pulley connected directly to the motor

- a belt between the smaller belt pulley and the belt pulley that is shown in the image.

Four forces (blue arrows) are acting on the bearings: 1. assembly weight (radial load) 2. belt tension (radial load) 3. impeller force (radial load) 4. impeller force (axial load)

Let’s break these forces down:

1. Assembly weight The full weight of the components in the image are held up by the two bearing assemblies. The force of the weight points perpendicularly to the axle, therefore the load acts radially on the bearings. Here’s the formula for this load:

2. Belt tension The belt between the two belt pulleys must not be loose in order for the small pulley (not in picture) to drive the big pulley efficiently. The tightness of the belt creates a tension force inside the belt which pulls down on the big pulley and the shaft that it’s connected to. When the belt is pulling the axle downwards, it creates a radial force in the bearings.

3. Radial Impeller force As the blades of the impeller spins, they create a centrifugal force pulling on the axle, much in the same way a ball can be felt pulling on your hand with a centrifugal force when you attach it to a piece of string and spin it in a circle. When the axle is pulled in this manner, it pushes against the bearing so that a radial load is created.

4. Axial impeller force The blades of the impeller creates a thrust on the axle making it want to go forward, much in the same way the blades on a propeller on a boat or an airplane makes the vehicle go forward. When an angled propeller blade spins, it pushes water or air behind it. Newton’s third law of motion states that for every action, there is an opposite and equal reaction – so when air or water is pushed backwards, a reaction force in the opposite direction, a thrust, is created which causes the boat or airplane to move forward. Of course the industrial fan is locked down and doesn’t have wheels on it so it remains stationary, but the thrust still creates a reaction force in the form of an axial load on the bearings.

Fr is equal to all radial loads acting on a bearing and Fa is equal to all the axial loads.

4.3)Calculate the Equivalent dynamic bearing load (P)

Depending on the load case the formula for P will vary;

P = F

when the load is constant in magnitude and direction and acts radially on a radial bearing or axially and centrically on a thrust bearing.

P = Fa

for certain thrust bearings that can only accommodate pure axial loads, such as thrust ball bearings and cylindrical and needle roller thrust bearings, provided that the load acts centrically.

P = XFr + YFa

if a bearing is loaded with simultaneously acting radial load Fr and axial load Fa that are constant in magnitude and direction

where

P equivalent dynamic bearing load [kN]

Fr actual radial bearing load [kN]

Fa actual axial bearing load [kN]

X radial load factor for the bearing

Y axial load factor for the bearing.

P = Fr + Y Fa

for tapered roller bearings and spherical roller bearings.

where

P equivalent dynamic bearing load [kN]

Fr actual radial bearing load [kN]

Fa actual axial bearing load [kN]

Y axial load factor for the bearing.

P = Fr

for cylindrical roller bearings

where

P = equivalent dynamic bearing load [kN]

Fr = actual radial bearing load [kN]

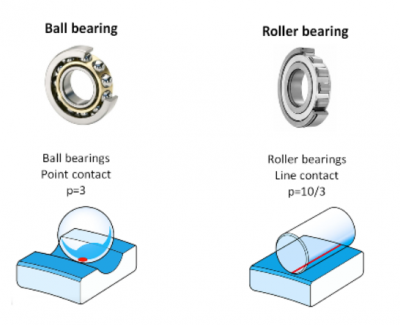

4.4) Determine the value for p-constant

The value of the constant p will depend on the bearing type;

p = 3 for ball bearings

p = 10/3 for roller bearings

p = 4 for pure line contact

4.5) Input C- and n-values of different bearings into L10h-formula until L10h-value matches desired L10h-value

The value for the Dynamic load rating (C) and the value for Rotational speed (n) is listed by the manufacturer or the designer.

Identify a bearing in a product catalog that corresponds to the following:

- the Bearing type that was selected in Step 2.

- an Inner diameter (aka. Bore diameter) that corresponds to the diameter of the axle.

Try different bearings by inputting their different C-values and n-values to the L10-formula (along with the values calculated for P, and p) until you reach a value that his higher than and as close as possible to the desired L10h-value you selected in step 4.1.

L10h = (10^6 / 60n) * ((C/P)^p)

where

L10h = bearing lifetime in hours

n = revolutions per minute

C = dynamic load rating (this value is listed by the manufacturer or the designer)

P = Equivalent dynamic bearing load

p = a constant depending on bearing type.

---

If you are interested in a bearing's lifetime in terms of number of revolutions rather than in terms of operational hours, the L10-formula (rather than the L10h-formula) is used.

L10 = basic rating life (measured in millions of revolutions).

L10 = (C/P)^p

where

C = dynamic load rating (this value is listed by the manufacturer or the designer)

P = Equivalent dynamic bearing load

p = a constant depending on bearing type.

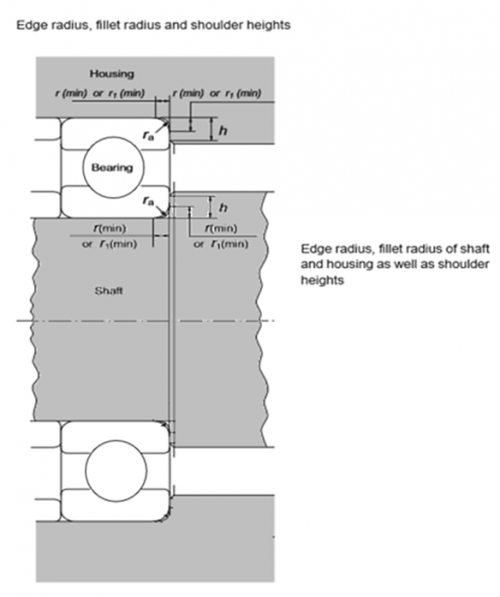

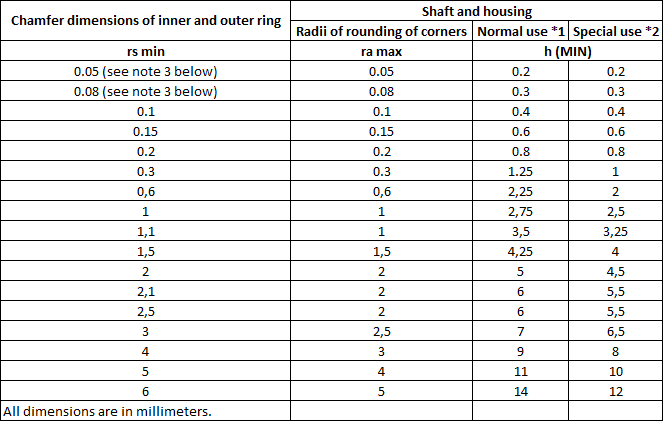

Step 5. Select bearing housing

The baring housing, aka known as bearing holder, is the component that supports the bearing.

Note: all dimensions are in millimeters.

Bearing risks

| Observed condition | Potential cause of failure | Solution |

|---|---|---|

| Flaking of the raceway surface | Flaking may be caused by excessive load, poor shaft or housing accuracy, poor installation or ingress of foreign objects. | If the load is too heavy, use a bearing with a larger capacity. If needed, use an oil with higher viscosity, or improve the lubrication system to form a protective film. |

| Peeling of the rolling surfaces | More likely to occur when lubrication is poor or the surfaces of opposite parts are rough. It may develop into flaking. | Control the surface roughness and choose a better lubricant. |

| Spalling on the ribs or raceway surfaces | May be caused by poor mounting, poor lubrication of the rolling elements or discontinuation of the protective film on the contact surfaces due to excessive load. | Improve the mounting, correct the load and select an adequate lubricant. |

| Smearing on the raceway surface | The rolling elements slip during the motion and the lubricant doesn't have the right characteristics to prevent slippage. | Select a proper lubricant or lubrication system and check the clearance and pre-load. |

| Raceway surface is worn and dimensions are reduced | Poor lubrication, ingress of a foreign object or contamination of lubricant with dirt or foreign objects. | Choose a proper lubricant or lubrication system, and improve the sealing efficiency. |

| Changes in surface colour and finish | A matted raceway surface or a discoloured surface may indicate poor lubrication, overheating or accumulation of deteriorated oil. | Improve the sealing efficiency and lubrication system, remove the oil with an organic solvent and polish with sandpaper to remove the roughness. |

| Indentations and hollows in the raceway surface | Probably caused by ingress of a solid object or by trapped particles. | Remove and keep out foreign objects, check for flakings and improve the handling procedures. |

| Chipping of the inner ring, outer ring or rolling elements | Chipping may be caused by excessive load, poor handling or trapped solid objects. | Check and improve the load, and improve the sealing efficiency. |

| Cracking in the rings or rolling elements | Excessive load, impact or overheating. A loose fit could also be the cause. | Examine and improve the load and correct the fit. |

| Rust or corrosion of the rings or rolling elements | Moisture, ingress of water or corrosive substances, or poor packing and storing conditions. | Improve the sealing efficiency, handling and storage. |

| Seizing of the rings or rolling elements | Poor heat dissipation due to poor lubrication or a too small clearance. Excessive load can also be the cause. | Improve the dissipation of heat and the lubrication. Check and improve the load. |

| Fretting of the raceways | Too much vibration, a small oscillation angle or poor lubrication. | The inner and outer ring should be transported separately, or the lubrication should be improved. |

| Damage of the cages | Excessive load, too high speed or large fluctuation of speed, poor lubrication or high vibration. | Improve the load conditions, reduce the vibration and improve the lubrication system. |

Other considerations

Consider listing values (such as C-value) for bearings that are designed and listed in the Bearing Part Library.

Consider making a bearing selection tool (as an assembly with multiple equation-driven configurations)in FreeCAD.

See also

Machine elements section under Basic calculations

OSE Bearing dimensioning calculator