RotoKnitic v19.01

Jump to navigation

Jump to search

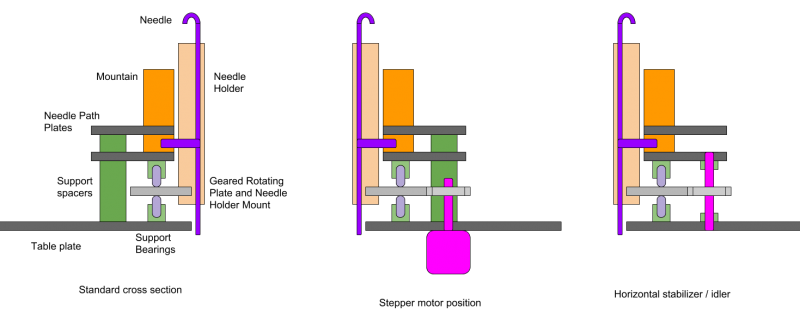

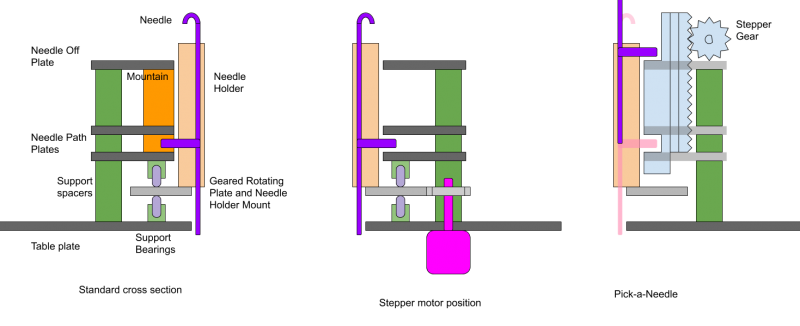

Using same parts and materials from OSE CircularKnitic v18.03, but switch mounting plates so that the mountain is stationary.

- requires spinning spool for fabric output

- allows for more multiple mountains and input threads

Design

- Needles will rotate around the machine instead of being stationary like in OSE_CircularKnitic_v18.03

- https://github.com/OpenSourceEcology/circular_knitic_pick-a-needle

Concept

Standard

Pick-a-Needle

Goals

- change direction

- sock heels

Needle Accomidation

- pick-a-needle, optionally raise needles to an inactive postion

- Test laser cut needles, printed latch?

- Test 3D printed needles

Fabric Spool

- Apply constant tension on fabric

- Roll onto spool for easy handling and storage

Improve Stepper Control

Provisional BOM

Part SCAD Code

Variable Profiles

CKvarsProfile_36in_201906.scad

/////////////////// USER SETTINGS /////////////////// ///////////// // USING THIS FILE: // choose desired settings below // rename and save this file into the "SCAD" folder // for example CKvarsProfile-Small2019.scad // then open the file named CKvars.scad in the "SCAD" folder // find the "include" commands at the begining of the file // change this information to the new file's name, then save // you can now open then render each part file with these settings ///////////// //File Notes - Large201903 // attempting to get near 45" 1100mm fabric width/circumference // ///////////// // DIMENSIONS //number of "p2" needle guides around circle //Jan2019 //small UPp2number=30; //12 //36 ///36 //12 //8 //number of needles mounted on each "p2" part UPp2needles=5; //5 //10 ///5 //5 //7 //number of "p3" parts around circle UPp3number=10; //4 //18 ///4 //4 //2 //number of "p4" parts around circle UPp4number=10; //4 //18 ///4 //4 //2 //distance from the inside face of one needle to the next UPneedle2needle=9.7; //default=14.35615 //try 8.414 //13.5334 //9.25 //mountain settings UPpMgrooveturnR=14; //radius of upper curved path in groove //14 //10 UPpMgrooveturnR2=7; //radius of lower curved path in groove //7 UPpMp3X=2.5; //length of lower plateu of groove //2.5 //2 UPpMp7X=3; //half of length of top plateu of groove //3 //2 UPnumberMountain=6; ///////////// // MATERIALS //thread diameter UPthreadD=2.5; //number of stepper motors driving the geared plate UPc1steppersnumber=UPnumberMountain; //laser cut part thickness UPupper_surfaceH=5; //thickness of upper rotating plate ///5 //6.35= 1/4"inch UPbottom_surface_motor_gearsH=5; //thickness of geared rotating plate UPtable_surface=10; //thickness of plate of main table UPtable_support=12.7; //thickness of support board below table surface //width of wood used to support table around the edges UPwoodbeamW=25.4; //table leg wood beam width 1.0 inch UPwoodbeamScrewOD=6; // M6 screw hole into wood beam //thread feeder option UPTF=1; // 0=none 1=angle iron 2=makerbeam10mm //angle iron option dimensions UPaaX=12.7; //width //12.7 = 1/2in UPaaT=1.5875; //thickness //1.5875 = 1/16in ///////////////////////////////////////////////

CKvars.scad

//////////////////////////////////////

///// Circular Knitic Variables //////

//////////////////////////////////////

//////////////////////////////////////

/////// CHOOSE MAIN SETTINGS ///////

//select the needle size file that will be used

include <CKvarsNeedle-KH260.scad>;

//select the settings profile file

include <CKvarsProfile_36in_201906.scad>;

//////////////////////////////////////

//////////////////////////////////////

/////// ADVANCED SETTINGS ///////

//number of "p2" parts around circle //Jan2019 //small

p2number=UPp2number; //12 //36 ///36 //12 //8

//number of needles mounted on each "p2" part

p2needles=UPp2needles; //5 //10 ///5 //5 //7

//number of "p3" parts around circle

p3number=UPp3number; //4 //18 ///4 //4 //2

//number of "p4" parts around circle

p4number=UPp4number; //4 //18 ///4 //4 //2

//distance from the inside face of one needle to the next

needle2needle=UPneedle2needle; //default=14.35615 //13.5334 //9.25

//number of mountains aka number of thread spools being used at a time

numberMountain=UPnumberMountain;

//calculated diameter from inside edge of needles

p2needlegrooveID=((needle2needle*p2number*p2needles)/PI);

//nnumber of Z bearing mounts

c1zmounts=max(p3number,4); //p3number //4

c1steppersnumber=UPc1steppersnumber; //number of stepper motors driving the gear

c1Sides=max(6,c1steppersnumber); //number of sides of plate

Td=5; //tooth depth-ish? - used to calculate # teeth large gear and pitch

////MATERIALS////

//thread diameter

threadD=UPthreadD;

//approx fabric circumference

echo("estimated fabric circumference", threadD*2*1.3*p2number*p2needles);

//thread feeder stand above mountain

TF=UPTF; // 0=none 1=angle iron 2=makerbeamm

TFW=60; //distance between outside edge of makerbream

aaX=UPaaX; //12.7 = 1/2in

aaT=UPaaT; //1.5875 = 1/16in

aaboltD=3;

aaboltHD=5.68;

aaboltHH=3;

aanutH=4;

aasqNutW=5.5;

aasqNutH=1.8;

aasqNutSlop=0.25;

pM2slop=0.35;

pM2H=aaX*3;

pM2mink=4;

pM2fH=10;

tipHole=3; //hole Size

tipOpenX=10;

tipOpenZ=10;

tipcylD=1.75; //1.5

tipcy2D=tipcylD*1.5;

//-(tipOpenX/2)+(tipcylD/2)

//thickness of upper rotating plate ///5 //6.35= 1/4"inch

upper_surfaceH=UPupper_surfaceH;

//thickness of geared rotating plate

bottom_surface_motor_gearsH=UPbottom_surface_motor_gearsH;

//thickness of plate of main table

table_surface=UPtable_surface;

//thickness of support board below main table

table_support=UPtable_support;

woodbeamW=UPwoodbeamW; //table leg wood beam width 1.0 inch

woodbeamScrewOD=UPwoodbeamScrewOD; // 1/4" screw hole

////PART SETTINGS////

//plate

pPplate1=bottom_surface_motor_gearsH; //thickness of geared plated

pPplate2=upper_surfaceH;

pPplate3=upper_surfaceH;

/*

//"connector0912" connects upper_surface plate to bottom_surface geared plate

connector0912H=12;

connector0912L=25;

connector0912W=8;

connector0912HoleOD=3; //hole diameter

connector0912HoleC2C=17; //center of hole to center of other hole

*/

//p5 BearringSmall1312_x_4.stl

bearingholderSmallB2C=5.5; //from base of bearing holder to center of bearing

bearingholderSmallBOD=10; //Outside Diameter of bearing

bearingholderSmallBID=4.9; //Inside Diameter of bore hole of bearing

bearingholderSmallBW=4; //Width of bearing

bearingholderSmallgaproll=0.05; //extra space to leave below bearing for rolling

bearingholderSmallgapclear=0.5; //extra space to leave above bearing inside holder

//BearringZ

bearingholderZBOD=10; //Outside Diameter of bearing

bearingholderZBID=4.9; //Inside Diameter of bore hole of bearing

bearingholderZBW=4; //Width of bearing //4

//p1 - stepper gear

NEMAshaftOD=5;

NEMAshaftCut=0.5;

NEMAshaftL=20; //length of shaft from motor face

NEMAshaftFL=15; //length of flat side of shaft

NEMAboltOD=3;

NEMAboltHeadH=3;

NEMAboltHeadOD=5.68;

NEMAboltHexOD=2.87;

NEMAfaceCricOD=22;

NEMAboltDis=31;

NEMAmotorW=42;

NEMAsetboltL=8; //length of M3 botl used for set screw

NEMAsetboltOD=3;

NEMAsetHeadOD=5.68;

NEMAsqNutW=5.5;

NEMAsqNutH=1.8;

NEMAsqNutSlop=0.25;

spurgearTn=16; //number of teeth on bull gear

//p2 - inner needle wall holder

needleWidthslop=0.4; //exta thickness

needleWidth=nX+needleWidthslop;

p2needlegroovefromID=2.0;

p2ID=p2needlegrooveID-(p2needlegroovefromID*2);

p2needlegrooveDepthslop=0.4; //exta thickness

p2needlegrooveDepth=nY+p2needlegrooveDepthslop;

//p2H calculated below;

p2W=p2needlegroovefromID+p2needlegrooveDepth;

p2OD=p2ID+(p2W*2);

//p2holeH calculated below

p2holeD=2; //depricate

p2holeCSD=4.01726; //depricate

p2holeCSL=1.5; //depricate

p2endtrim=0.5; //trim end of wall to give room between p2's

p2p3boltType=2; //1 = reg cap screw, 2 = flat cap screw

//type 1

p2p3boltD=3;

p2p3boltHH=3;

p2p3boltHD=5.68;

//type 2

p2p3flatD=3;

p2p3flatHA=90;

p2p3flatHD=6.72; //listed as 6.72 max 5.54 min

p2p3flatHH=1.86;

p2p3nutH=4;

p2p3nutOD=6.01;

p2p4type=0; //0 for regular, 1 for flat

p2p4flatD=2;

p2p4boltD=2;

p2p4flatHA=90; //angle between head's slopes

p2p4flatHD=6.72; //listed as 6.72 max 5.54 min

p2p4boltHD=4.16; //head Diameter

p2p4flatHH=1.86;

p2p4boltHH=2; //head height

p2p4nutH=1.6;

echo("p2 lower bolt L",p2W+p3upperwallW+0); //fix

echo("p2ID", p2ID);

//p3 - outer needle wall slide

p3wiggle=0.1;

p3baseH=3; //height of outer base

p3wallW=(nH-nY)/2; //half of needle butt

p3upperwallW=3;

p3baseholeD=3;

p3baseholeScrewHeadD=5.68;

p3baseholefromODID=p3baseholeScrewHeadD/2;

p3baseholenumber=4;

p3ridgeW1=3;

p3ridgeW2=5;

p3ridgeH=5;

p3wallholefromtop=5;

p3wallchamfW=2;

p3wallchamfH=3;

//p3wallH in calculations below

//p3grooveH1 in calculations below

//p3grooveH2 in calculations below

p3grooveHslop=1;

p3grooveWslop=0.8; //extra Width in needle groove

p3grooveW=nX+p3grooveWslop;

p3clear=5; //distance from top of p3 to needle flipper in down position

p3baseID2N=2; //clearance between baseID and needles

p3baseID=p2OD+(p3baseID2N*2);

p3baseOD=p2OD+(p3wiggle*2)+(p3wallW*2)+(p3wallchamfW*2)+(p3baseholeScrewHeadD*2);

centerlineD=p2ID+(p2W+(p3wiggle*2));

p3wallOD=centerlineD+(p3wallW*2)+((p2W+(p3wiggle*2)/2));

p3wallID=centerlineD+((p2W+(p3wiggle*2)/2));

p3base45W=p3ridgeW2+p3wiggle+p2W+p3wiggle+p3baseID2N;

p3base45H=p3base45W; //height of 45 degree overhang

p3needleholefactorW=1.5; //multiply width of needle tail hole in base by this

p3endtrim=0.5;

//p4

p4rampH=14.57;

p4rampfromID=2.5;

p4rampoverhangH=4;

p4rsH=p4rampH-p4rampoverhangH; //height of ramp surface

p4rampfromOD=1.34;

p4rampC1=10;

p4rampC2=40;

p4rampC2transX=10;

p4rampC2transZ=3.82;

p4basegapH=max(p2p4flatD*3,8);

p4baseH=p4basegapH+nD; //sin(45) of angle from front of needle??

p4baseW=11.2;

p4basegapW=p2W+0.2; //5.09

p4clawW=min((needle2needle-(nX*2)),9);

p4holesnumber=3;

p4holeH=p4basegapH/2;

p4rampW=max(min(p4clawW-3,4),2.5);

p4rampMinkD=(p4rampW/3)*2; //minkoski diameter

p4rampWm=p4rampW-p4rampMinkD;

p4clear=-0.5; //distance above top of p4 from flipper in down position //need to fix -0.5? //-p4rampH*(1/3) or -5?

//p4clear maybe need to calculate sin(45) distnace from top of baseH, distance from OD of needle to ID of base

p4endtrim=0.5;

p4clawWslanttop=1; //0 = slant to rampW, p4rampW = no slant

echo("rampW", p4rampW);

//space between rotating plates

pPextra=1; //extra room below nC at lowest point

pPspace2=nC+(p4baseH-p4basegapH)+pPextra; //space between geared plate and mountain plate, needle nC? //12

//p5 small bearing holder

p5boltHeadOD=8; //look up sales drawing - used to cut mountain

p5boltHeadH=3.65; //look up sales drawing - used to cut mountain

p5nutH=3; //jam nut

p5boltD=5;

p5boltL=25; //bolt to hold bearings

p5wingW=7;

p5wingL=p5boltHeadH+p5boltL;

p5wingH=3;

p5bodyW=bearingholderSmallBOD+6;

p5bodyL=p5boltL-p5nutH;

p5bearCl=1.5; //distance from top of body to OD of bearing

p5bodyH=bearingholderSmallgapclear+bearingholderSmallBOD-p5bearCl;

p5wiggleL=0.4; //clearnace around bearing

p5wiggleW=0.25; //clearnace around bearing

p5bearingfromwall=4.25;

p5mountholeOD=3; //mounting bolt OD

p5mountBoltHeadOD=5.68;

pPspace1=bearingholderSmallgapclear+bearingholderSmallBOD+bearingholderSmallgaproll; //? space from main table top to first plate - calc w/ bearing holder height, stepper motor shaft length?

//made max of bearing holder, and p3wall45H?

echo("pPspace1",pPspace1);

p1H=pPspace1+pPplate1+1;

//p6 big bearing holder - depricated

p6wingW=30;

p6wingL=25;

p6wingH=3;

p6bodyW=16;

p6bodyL=25;

p6bodyH=9.5;

p6wiggleL=0.4;

p6wiggleW=0.6;

p6bearingfromwall=4.25;

p6mountholeOD=3;

p6mountholeHeadOD=5.68; //OD of socket screw head

p6mounthole2front=8;

p6mounthole2side=3;

//p7 Z bearing holder - need to tweak more for different size bearings

//bearing bolt

p7boltHeadOD=8; //look up sales drawing - used to cut mountain

p7boltHeadH=3.65; //look up sales drawing - used to cut mountain

p7nutH=2.7; //jam nut

p7boltD=5;

p7boltL=16; //bolt to hold bearings

p7baseH=4;

p7wallW=3;

p7mountH=bearingholderZBOD-2;

p7mountholeOD=3;

p7mountholeHeadOD=5.68;

p7mountnutOD=6.01;

p7mountnutH=3;

p7mounthole2edge=4.5;

p7bearingfromfront=3;

p7wiggleL=0.4;

p7wiggleW=0.25;

p7baseW=bearingholderZBOD+8; //16

p7baseL=max((((p7bearingfromfront+bearingholderZBW+p7bearingfromfront)*2)+p7wallW),(p7mountholeHeadOD*2)+p7wallW,(p7mounthole2edge*2)+p7wallW); //23

p7mountL=(p7baseL-p7wallW)/2; //13

echo("suggested boltL for Z bearing", ceil(((((p7baseL-p7wallW)/2)+p7wallW+p7nutH)/2))*2 );

//p8 plate connector

p8boltHeadOD=5.68; //look up sales drawing - used to cut mountain

p8boltHeadH=3; //look up sales drawing - used to cut mountain

p8nutH=4; //jam nut

p8boltD=3;

p8boltL=30; //bolt to hold bearings ????

p8baseW=8;

p8holeD=p8boltD;

p8H=pPspace2;

echo("suggested boltL for spacer", ceil((upper_surfaceH+pPspace2+bottom_surface_motor_gearsH+p8nutH)/5)*5 ); //20,22,25,30 commonly availabble

//p9 outer connector

p9thickness=3;

p9H=10;

//mountain

pMwallT=9; //min thickness from groove to back wall //7.5 //10

pMgroove=nH-nY-p3wallW+1; //depth of groove

pMgrooveSlop=0.5; //height slop of groove

pMgrooveD=nC+pMgrooveSlop; //Z plane diamter of groove cut

pMgrooveAngle=45; // only 45 is working

pMgrooveC1=pPspace2; //top of groove at position 1 "entrance" pPspace2 ///////////

pMgrooveC2=nC+pPextra; //top of groove at position 2 "push down" nC+2 ////////////

echo("pushdown distance",pPspace2-(nC+pPextra));

threadthickness=0.5; //approx used to leave space above p2

pMgrooveC3=pMgrooveC2+(pMgrooveD-nC)-(nG+threadthickness)+(p4baseH-p4basegapH)+p4rampH+p4clear+nF; //top of groove at position 3 "top center" calc! //44.25

pMwallHextra=3.75; //extra height above groove at heighest point

pMH=pMwallHextra+pMgrooveC3; //total height of mountain

pMshelfH=4; //thickness of shelf resting on top of c3 - depricated

pMshelfchamfR=3; //radius of chamfer at join shelf/wall

pMshelfBoltD=3;

pM3c2c=(pMH-(aaboltHD/2)-5)-((pPspace2+pPplate2+1)+(aaboltHD/2)+bearingholderZBOD);

pM3c2e=min(

pMH-(pMH-(aaboltHD/2)-5)

,

((pPspace2+pPplate2+1)+(aaboltHD/2)+bearingholderZBOD)

-(pMshelfchamfR+pPspace2+pPplate2)

);

//distance between bolts + 2X the min distance from bolt to top or bolt to bottom

pM3H=(

pM3c2c

+(2*min(

pMH-(pMH-(aaboltHD/2)-5)

,

((pPspace2+pPplate2+1)+(aaboltHD/2)+bearingholderZBOD)

-(pMshelfchamfR+pPspace2+pPplate2)

))

);

pM3mink=6;

pM3slop=0.25;

pMsqNutW=5.5;

pMsqNutH=1.8;

pMsqNutSlop=0.25;

//pS1 - pick a needle geared riser

pS1W=(needle2needle-nX)/2; //width

pS1wallT=4; //Cross section to fit in guide groove

pS1wallW=pS1W+8;

pS1T=8; //thickness of vertical section without gears

pS1GearD=10; //filler for now, TODO calculate

pS1Z=pPplate1+pMH+pPplate3+pMgrooveD+pS1GearD;

//c2 geared plate - clean up below, not used to generate gear

c2H=bottom_surface_motor_gearsH;

c2gap=0.5; //gap between c2ID and p3wallOD // 0.7? 0.5? 0.35? how low can you go?

c2t2t=6.858;

c2width=50; //depricated?

c2OD=p3baseOD+(p5boltL*2)+(p5boltHeadH*2)+(Td*2)+(2*2);

c2ID=(c2gap*2)+p2OD+(p3wiggle*2)+(p3wallW*2); //should this be p3wallOD+(c2gap*2)

c2teeth=((c2OD*PI)/c2t2t);

c2dipitch=c2teeth/(c2OD*PI);

cWiggle=0.1; //extra height on mountaint cutout for c3 to sit in ?? is this used ??

/////////////////////

//calculated settings

/////////////////////

bearingholderZB2C=(bearingholderZBOD/2)+pPspace1+pPplate1+pPspace2+pPplate2; //from base of bearing holder to center of bearing

rez=p2number*p2needles*2;

centerlineD=p2ID+(p2W+(p3wiggle*2));

p3grooveH1=pPspace1+pPplate1; //bottom of verticle groove in p3

p3grooveH2=pPspace1+pPplate1+pMH+pPplate3+pMgrooveD; //top of groove in p3

p4baseOD=centerlineD+p4baseW;

p4baseID=centerlineD-p4baseW;

p4basegapOD=centerlineD+p4basegapW;

p4basegapID=centerlineD-p4basegapW;

//firstcenter=(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2))/2;

//doesnt work on narrow needle arrangement, moved to second gap

p2H=pPspace1+pPplate1+pMgrooveC2+(nA-nC-nB-nG)-threadthickness-p3base45H;

p3wallH=pPspace1+pPplate1+pMgrooveC2+nA-nB-nC-nF-p3clear;

p2holeH=p3grooveH2+((p3wallH-p3grooveH2)/2); //hight from table top

//c3

c3ID=c2ID;

c3H=upper_surfaceH;

//c6

c6H=c3H;

pMID=c2ID;

pMODwall=c2ID+(pMgroove*2)+(pMwallT*2);

//c4 paper clip connecting weight holder plate

c4OD=p2ID-(p3ridgeW2*2)-(20*2);

c4paperclipholeD=5;

c4paperclipholeW=2;

c4paperclipholetoEdge=3;

/////////////////////////////////

pMgrooveOR=pMgroove+(pMID/2); //center to OD of groove

// is this supposed to be the radius?

/////////////////////////////////

c5OD=pMgrooveOR*2;

c5H=upper_surfaceH;

////////////////////////

// MOUNTAIN VARIABLES //

////////////////////////

mult=20; //rough multiplier 5-30

grez=rez*mult; //number of sides of groove path main circle

gdeg=360/grez; //standard fraction of a degree per groove rez

glen=(pMID*PI)/grez; //length of arc of each rez's fraction of a degree

glnd=glen/gdeg; //length of standard fraction of a degree

gcho=2*(pMID/2)*sin(gdeg/2); //chord length of glnd

garc=gdeg*(pMID/2); //arc length... too close to get to smaller digits that are diff?

echo("rez", rez);

echo("grez", grez);

echo("gdeg", gdeg);

echo("glen", glen);

echo("glnd", glnd);

echo("pMgrooveC3", pMgrooveC3);

//radius of upper curved path in groove //14 //10

pMgrooveturnR=UPpMgrooveturnR;

//radius of lower curved path in groove //7

pMgrooveturnR2=UPpMgrooveturnR2;

pMgrooveturnR3=7; // radius of entrance curved path - not used

pMcutRez=2; //cuts per degree

pMcutcylRez=36; //number of sides on groove cutting clylinder

pMcutA=45; //angle of cut path

//7

pMp7X=UPpMp7X; //half of length of plateu of groove. preferably whole number //3 //2

pMd7=pMp7X/glnd; //number of degrees for entire groove7

pMd7s=0; //degree turn to center of groove

pMd7e=pMd7; //highest degree turn for section 7

pMh7s=pMgrooveC3-(pMgrooveD/2); //height of center of groove

pMh7e=pMgrooveC3-(pMgrooveD/2);

//6

pMp6X=cos(90-pMcutA)*pMgrooveturnR;

pMd6=pMp6X/glnd;

pMd6s=pMd7e;

pMd6e=pMd7e+pMd6;

function func6(i) = (pMgrooveturnR*cos(asin(((i-pMd6s)*(pMp6X/pMd6))/pMgrooveturnR))-pMgrooveturnR);

pMh6s=pMh7e;

pMh6e=pMh7e+func6(pMd6e);

//5

pMh5s=pMh6e;

pMh5e=0;

pMp5X=(pMh5s-pMh5e)*tan(90-pMcutA);

pMd5=pMp5X/glnd;

pMd5s=pMd6e;

pMd5e=pMd6e+pMd5;

//4

pMh4e=pMgrooveC2-(pMgrooveD/2);

pMp55X=(pMgrooveturnR2*tan(90-pMcutA))-(pMgrooveturnR2*sin(90-pMcutA))+(pMh4e/tan(90-pMcutA));

pMd55=pMp55X/glnd;

pMp4X=cos(90-pMcutA)*pMgrooveturnR2; /////////problem with non-45 angles, p55X?

pMd4=pMp4X/glnd;

pMd4s=pMd5e-pMd55;

pMd4e=pMd5e-pMd55+pMd4;

function func4(i) = -(pMgrooveturnR2*cos(asin(((pMd4e-i)*(pMp4X/pMd4))/pMgrooveturnR2))-pMgrooveturnR2);

pMh4s=func4(pMd4s);

//3

pMp3X=UPpMp3X; //length of lower plateu of groove //2.5 //2

pMd3=pMp3X/glnd; //number of degrees for groove section 3

pMd3s=pMd4e; //degree turn to center of groove

pMd3e=pMd4e+pMd3; //highest degree turn for section 7

pMh3s=pMh4e; //height of center of groove

pMh3e=pMh4e;

//2

pMp2X=cos(pMcutA)*pMgrooveturnR2;

pMd2=pMp2X/glnd;

pMd2s=pMd3e;

pMd2e=pMd3e+pMd2;

function func2(i) = -(pMgrooveturnR2*cos(asin(((i-pMd2s)*(pMp2X/pMd2))/pMgrooveturnR2))-pMgrooveturnR2);

pMh2e=pMh3e+func2(pMd2s);

pMh2s=pMh3e;

//1

pMh1s=pMh2e;

pMh1e=pMgrooveC1-(pMgrooveD)+((pMgrooveD/2)-(sin(pMcutA)*(pMgrooveD/2))); //-(cos(pMcutA)*pMgrooveturnR3); //-(pMgrooveD/2)

pMp1X=((pMh1e)-(pMh1s))*tan(90-pMcutA); //-sin(45)*grooveD/2 ??

pMd1=pMp1X/glnd;

pMd1s=pMd2e;

pMd1e=pMd2e+pMd1;

echo("extra to subtract??",sin(pMcutA)*(pMgrooveD/2));

//0

// pMp0X=pMgrooveD/2; //pMgrooveD

// pMd0=pMp0X/glnd; //pMgrooveD/glnd; //define later

pMp0X=0;

pMd0=pMp0X/glnd;

pMd0s=pMd1e;

pMd0e=pMd1e+pMd0;

//pM0 attempt to make curve below

/*

pMp0X=cos(90-pMcutA)*pMgrooveturnR3;

pMd0=pMp0X/glnd;

pMd0s=pMd1e;

pMd0e=pMd1e+pMd0;

function func0(i) = (pMgrooveturnR3*cos(asin(((i-pMd0e)*(pMp0X/pMd0))/pMgrooveturnR3))-pMgrooveturnR3);

pMh0s=pMh1e;

pMh0e=pMh1e+func0(pMd0e);

*/

//mounting shelf and holes settings

pMshelfX=pMshelfBoltD*4; //length of shelf in mm

pMshelfd=pMshelfX/glnd; //number of degrees of shelf

pMdS=(pMgrooveD/2)/glnd; //to trim half

pMdSs=pMd1e+pMdS;

pMshelfHole1X=pMshelfchamfR+(pMshelfBoltD*1.5); //distance to hole center from main body

pMshelfHole1d=(pMshelfHole1X/glen)*gdeg; //number of degrees from edge to hole center

pMshelfHole2X=pMshelfX-(pMshelfBoltD*1.5); //distance to hole center from main body

pMshelfHole2d=(pMshelfHole2X/glen)*gdeg; //number of degrees from edge to hole center

pMextman=0.0002; //increase size of filler piece to make part manifold correctly

pMbodyXr=(((c2ID+(pMgroove*2))/2)*cos(90-(pMd1e-pMd0))); //half the X of back wall

//END MOUNTAIN VARS

///////////////////////

//c3 - redo with extra mountian tab/shelf distance

c3OD=

max(

((pow((pow((pMbodyXr+pMshelfX),2)+pow((((c2ID+(pMgroove*2)+(pMwallT*2))/2)),2)),1/2))*2)+((p7mountL+p7boltHeadH)*2)

,

((((p3baseOD/2)+1+p5wingL+1+p7bearingfromfront+(p7wiggleL/2)+bearingholderZBW))*2)

);

//removed following, going to shrink p8 as needed

//(((pMID/2)+(pMgroove)+1+(p8baseL/2)+(p8holeC2C/2)+(p8holeD*1.25)+(p7mountL))*2)

//MAX() of distance from mountain, and distance from plate spacers bolts

//need to consider tooth size on plate c2 ??

echo("X", (pMbodyXr+pMshelfX));

echo("Y", ((c2ID+(pMgroove*2)+(pMwallT*2))/2));

echo("c3OD=", c3OD);

echo("pMID less pMbodyXr*2",pMID-(pMbodyXr*2)); //needs to be positive

pMODshelf=c3OD;

pMarcL=((PI*c2ID)*((pMd1e-pMd0)*2)/360); //approx arc length of mountain - could get more accurate number

echo("pMarcL",pMarcL);

pMmaxNum=floor((PI*c2ID)/pMarcL); //max number of mountains around circumference

echo("pMmaxNum",pMmaxNum);

pMnum=floor(pMmaxNum/2);

echo("pMnum",pMnum);

//number of sets of bearings mounted to geared plated

c2bmounts=max(3,pMnum*2); //p3number //probably should be higher

echo("c2bmounts",c2bmounts);

p7number=(ceil(max(

c2bmounts*1.3,

4

)/4))*4;

echo("p7number", p7number);

//number of plate connectors

//c2connectors=pMnum*3; // need to tweak so does not overlap mountain footprint

c2connectors=numberMountain;

/////gear calcs/////

//solve for # of teeth and circ_pitch that gives proper tooth whole depth

Tn=floor(((-2*c2OD)/((c2OD-Td)-c2OD))-2); //number of teeth? - for big gear

pCir=180*(c2OD-(Td))/Tn; //circular pitch - use for both big and small gear

CKp1_circular_pitch=pCir;

CKp1_number_of_teeth=spurgearTn;

CKp1_pitch_diameter = CKp1_number_of_teeth * CKp1_circular_pitch / 180;

CKp1_pitch_radius = CKp1_pitch_diameter/2;

CKc2_circular_pitch=pCir;

CKc2_number_of_teeth=Tn;

CKc2_pitch_diameter = CKc2_number_of_teeth * CKc2_circular_pitch / 180;

CKc2_pitch_radius = CKc2_pitch_diameter/2;

echo("c2OD",c2OD);

echo("Tn",Tn);

echo("pitch",180*(c2OD-(Td))/Tn);

echo("pCir",pCir);

p5mounthole2front=(p5mountBoltHeadOD/2)+Td;

p5mounthole2back=

max(

(p5mountBoltHeadOD/2)+(((pMID+(pMgroove*2))-(p3baseOD+2))/2)

,

(p5mountBoltHeadOD/2)+4

);

//p8

p8holeend2C=4;

p8innerboltO2C=(c2ID/2)+pMgroove+1+p8holeend2C; //radius of origin to center of inner bolt

p8outerboltO2C=min(

(c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW-p7boltHeadH-1-(p8boltHeadOD/2)

,

CKc2_pitch_radius-(Td/2)-1-p8holeend2C

); //radius of origin to center of outer bolt

p8holeC2C=p8outerboltO2C-p8innerboltO2C; //p8baseL-(p8holeend2C*2)

p8baseL=p8holeC2C+(p8holeend2C*2); //25

p8dsqNutW=5.5;

p8dID=c2OD+3;

p8dH=pPspace1+pPplate2+pPspace1;

p8dD=15; //degrees around circle for each p8d

p8dboltD=3;

p8dsqNutH=1.8;

p8dsqNutSlop=0.25;

p8eNutH=5;

p8eboltD=3;

//p8d

p8dminT=p8dsqNutW+1;

//c1

c1H=table_surface;

c1width=c2width+91.36; //depricated?

c1OD=(CKp1_pitch_radius+CKc2_pitch_radius+(NEMAmotorW/2)+woodbeamW+2)*2; // c2OD + (c1width-c2width);

c1zOD=(((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW+(p7baseL-p7mounthole2edge))+woodbeamW+2)*2; //outside diameter of plate at Z mounts

c1W=max(

c1OD*(-ceil(1/(floor( (2-c1steppersnumber)*(c1steppersnumber/(2/c1steppersnumber)) )+1))+1)

,

c3OD

);

test=1;

echo("floor",

(-ceil(1/(floor( (2-c1steppersnumber)*(c1steppersnumber/(2/c1steppersnumber)) )+1))+1)

); //if there are more than 2 steppers = 1

echo("c3OD",c3OD);

echo("c1W",c1W);

c6OD=c3OD+(p8dminT*2);

p8dOD=c6OD;

UPc1W=c6OD;

c1polyOD=c6OD; //need to calculate stepper OD later

//p2 flat socket head screw

p2p3flatORmax=((c2ID+sqrt((-4*(p2p3flatHD/2)*(p2p3flatHD/2))+((c2ID)*(c2ID))))/2)/2; //maximum radius to be within c2ID

//thread feeder

M2tipY=tipOpenX/2; //pM2mink

M2tipZ=(((tipOpenX/2)-(nE/2))*2)+tipHole+(tipcylD/2);

M2tiptopC=(((tipOpenX/2)-(nE/2))*2)+tipHole+(tipcylD/2)-(pM2mink/4);

M2inX=((((c2ID+(pMgroove*2))/2)*cos(90-(pMd1e-pMd0)))-pMshelfchamfR-(aaX-aaT))*2;

M2inY=(((c2ID+(pMgroove*2)+(pMwallT*2))/2))-((p3wallID/2)-(p2needlegrooveDepthslop/2))-(nD-nY)-nD; //(M2tipY) //(nD-nY) //tipcylD/2

M2inZ=pM2H-pM2mink;

M2backwallOD=((c2ID+(pMgroove*2)+(pMwallT*2))/2)+aaT;

////SETTINGS OUTPUT ECHOS///

echo("Total Needles:", p2number*p2needles);

echo("Millimeters Between Needles:", PI*p2needlegrooveID/(p2number*p2needles));

echo("OD of p3:", p3baseOD);

echo("OD of c1:", c2OD+(c1width-c2width));

/////BOM COUNT///////

if(TF==1){

echo("Thread Feeder Mount Bolt: (2)", (ceil(((((pMID/2)-(cos(pMd4s)*(pMID/2)))+pMwallT+pMgroove)-(sin(pMd4s)*(aaboltHD))-2-aaboltHH+aaT+aanutH)/2)*2) );

}

Needles

CKneedleVars-KH260.scad

- purchased here: http://shop.sckmcl.com.hk/product_info.php?products_id=136

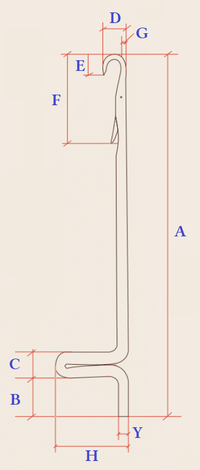

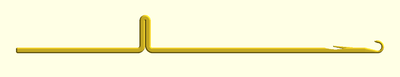

//NEEDLE for Brother KH260 //measurements by dorkmo nX=1.4; //typical thickness from side to side nY=2.44; //typical thickness from front to back nA=157.9; //total length of needle nB=53; //distance from bottom of needle to bottom of bent tab. nC=4.82; //thickness of bent tab. top to bottom. nD=5.48; //hook front to back nE=4.10; //from top of loop to bottom of hook nF=22.0; //from top of loop to bottom of flipper in down position nG=1.10; //minimum thickness of hook. front to back. nH=17.03; //max distance from front to back nT=0; //0=straight tail 1=bent tail aka folded back. Y of tail = C if T=1.

CKneedleVars-SK120.scad

- difficult to find these exact needles for sale

//NEEDLE for SK120 //measured by original CircularKnitic team nX=1.4; //typical thickness from side to side nY=2.44; //typical thickness from front to back nA=97.73; //total length of needle nB=7.72; //distance from bottom of needle to bottom of bent tab. nC=4.92; //thickness of bent tab. top to bottom. nD=5.09; //hook front to back nE=4.62; //from top top loop to bottom of hook nF=19.94; //top to bottom of flipper in down position nG=1.04; //minimum thickness of hook. front to back. nH=16.4; //max distance from front to back nT=0; //0=straight tail 1=bent tail aka folded back. Y of tail = C of T=1.

2D Laser Cut Parts

3D Printed Parts

p4 "yarn holder"

include <CKvars.scad>;

CKp4();

module CKp4(){

rez=p2number*p2needles*2;

$fn=rez; //defines resolution of circles.

translate([p4baseOD/2,0,0]){

difference(){

union(){

cylinder(h=p4baseH,d=p4baseOD-(p4basegapW*2)-((p4baseW-p4basegapW)/2*2));

//ramps

for(i=[1:p2needles*(p2number/p4number)]){

rotate([0,0,(360/p2number/p2needles)-(360/p2number/p2needles*i)-(((360/p2number/p2needles))/2)]){

difference(){

minkowski(){

union(){

translate([-p4baseOD/2+p4rampfromOD,p4rampWm/2,p4rampH+p4baseH-(p4rampC1/2)])

rotate([90,0,0])

cylinder(h=p4rampWm,d=p4rampC1);

intersection(){

translate([-10,0,3.82])

translate([-p4baseOD/2+p4rampfromOD,p4rampWm/2,p4rampH+p4baseH-(p4rampC2/2)])

rotate([90,0,0])

cylinder(h=p4rampWm,d=p4rampC2);

translate([-7,0,-2.86/2])

translate([-p4baseOD/2+p4rampfromOD,p4rampWm/2,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

}

}//end union

difference(){

translate([-p4rampMinkD/2,0,0])

cylinder(d=p4rampMinkD,h=0.01, $fn=36);

translate([-p4rampMinkD,0,-0.01])

cube([p4rampMinkD,p4rampMinkD,0.02], center=true);

} //end diff

} //end mink

translate([-p4rampC2/2,0,0])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2+1],center=true);

translate([0,0,0])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4baseH-(p4rampC2/2)-0.1])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([0,-p4clawW/2,0])

translate([-(p4baseID/2)-p4rampfromID,0,p4baseH])

cube([(p4baseID/2)+p4rampfromID,p4clawW,p4rampoverhangH]);

translate([-7,0,0])

translate([-p4baseOD/2+p4rampfromOD,(p4rampW/2)+(p4rampC2/2)-0.01,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([-7,0,0])

translate([-p4baseOD/2+p4rampfromOD,-(p4rampW/2)-(p4rampC2/2)+0.01,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

}//end ramps difference

} //end for rotate

} //end for

//claws

for(i=[1:p2needles*(p2number/p4number)]){

rotate([0,0,(360/p2number/p2needles)-(360/p2number/p2needles*i)-(((360/p2number/p2needles))/2)]){

hull(){

translate([-p4baseOD/2,-p4clawW/2,0])

#cube([(p4baseOD-p4baseID)/2,p4clawW,p4basegapH]);

translate([-p4baseOD/2,-((p4rampW+p4clawWslanttop)/2),p4baseH-0.1])

#cube([(p4baseOD-p4baseID)/2,p4rampW+p4clawWslanttop,0.1]);

} //end hull

}

}//end for

} //end main union

cylinder(h=p4baseH,d=p4baseID);

//simiple chamfer of inside corner

translate([0,0,p4baseH-0.5])

cylinder(h=0.5,d1=p4baseID+0.5,d2=p4baseID+1.9);

translate([0,0,p4baseH-0.5-0.5])

cylinder(h=0.5,d1=p4baseID,d2=p4baseID+0.5);

translate([-p4baseOD/2,-p4baseOD/2,0]){

cube([p4baseOD,p4baseOD/2,p4baseH]);

}

rotate([0,0,-360/p4number]){

translate([-p4baseOD/2,0,0])

cube([p4baseOD,p4baseOD/2,p4baseH]);

}

difference(){

cylinder(h=p4basegapH,d=p4basegapOD);

cylinder(h=p4basegapH,d=p4basegapID);

}

//bolt holes

for(i=[0:(p2number/p4number)-1]){

rotate([0,0,(-360/p2number/p2needles*0.5)+(i*-360/p2number)]){

if(p2p4type==1){

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

cylinder(d1=p2p4flatHD,d2=0,h=(p2p4flatHD/2)/tan(45),$fn=36);

translate([0,0,-(p2p4flatHD)/tan(45)])

cylinder(d1=p2p4flatHD*3,d2=p2p4flatHD,h=(p2p4flatHD)/tan(45),$fn=36);

cylinder(d=p2p4flatD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

if(p2p4type==0){

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

translate([0,0,-p2p4boltHH/2])

cylinder(d=p2p4boltHD,h=p2p4boltHH,$fn=36);

cylinder(d=p2p4boltD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

}

}

//second set

for(i=[0:(p2number/p3number)-1]){

rotate([0,0,-(360/p2number/p2needles*0.5)+(360/p2number/p2needles)+(i*-360/p2number)+(-360/p2number)]){

if(p2p4type==1){ // if flat socket

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

cylinder(d1=p2p4flatHD,d2=0,h=(p2p4flatHD/2)/tan(45),$fn=36);

translate([0,0,-(p2p4flatHD)/tan(45)])

cylinder(d1=p2p4flatHD*3,d2=p2p4flatHD,h=(p2p4flatHD)/tan(45),$fn=36);

cylinder(d=p2p4flatD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

if(p2p4type==0){ // if regular socket

translate([-(p4baseOD/2)+((p4baseOD-p4baseID)/2),0,p4holeH])

rotate([0,270,0])

translate([0,0,0])

union(){

translate([0,0,-p2p4boltHH/2])

cylinder(d=p2p4boltHD,h=p2p4boltHH,$fn=36);

cylinder(d=p2p4boltD,h=((p4baseOD-p4baseID)/2)+2,$fn=36);

}//end union

}//end if

} //end rotate

} //end for

//end mounting holes

//trim end

if(p4number>1){

rotate([0,0,-(360/(p4baseOD*PI/p4endtrim))])

mirror([1,1,0])

cube([p4baseOD/2,p4baseOD/2,p4rampH+p4baseH]);

}

} //end main difference

} //end main translate

} //end module

Parts

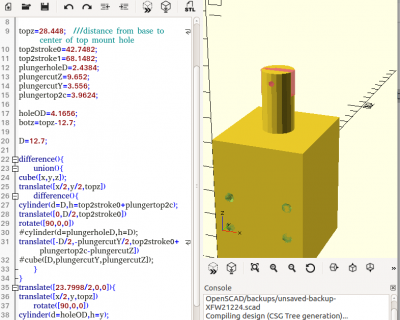

Pontiac Coil L-09

PCL90();

module PCL90(){

x=36.576;

y=41.402;

z=51.308;

topz=28.448; ///distance from base to center of top mount hole

top2stroke0=42.7482;

top2stroke1=68.1482;

plungerholeD=2.4384;

plungercutZ=9.652;

plungercutY=3.556;

plungertop2c=3.9624;

holeOD=4.1656;

botz=topz-12.7;

D=12.7;

difference(){

union(){

cube([x,y,z]);

translate([x/2,y/2,topz])

difference(){

cylinder(d=D,h=top2stroke0+plungertop2c);

translate([0,D/2,top2stroke0])

rotate([90,0,0])

#cylinder(d=plungerholeD,h=D);

translate([-D/2,-plungercutY/2,top2stroke0+plungertop2c-plungercutZ])

#cube([D,plungercutY,plungercutZ]);

}

}

translate([23.7998/2,0,0]){

translate([x/2,y,topz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

translate([x/2,y,botz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

}

translate([-23.7998/2,0,0]){

translate([x/2,y,topz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

translate([x/2,y,botz])

rotate([90,0,0])

cylinder(d=holeOD,h=y);

}

}//end main diff

}//end module

Full Assembly

BOM

TODO

- remove p8 plate connector under mountain

- put hole for makerbeam on plate below

- breakup tabletop plate into multiple pieces to make max size smaller

- could make all cut plates hexagons except for geared plate.

- could make geared a little larger if move support spacer to bridge stepper gear

- tweak outiside diameter values to remove p9

- change p9 to a simple p8 variant near steppers

- could just set p9 thickness to zero for now