OSE Shop 2011

Main > Housing and construction

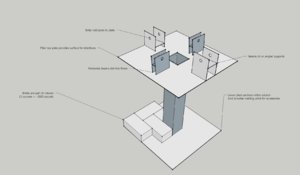

A 12 cell (16'x16') workshop for prototyping and production runs of open source ecology machines

Steps taken to recycle and use a roof structure built as a prototype are shown on the OSE Shop 2011/OSE Mill Shed 2011 page.

See also the prototypical CEB Living Unit

See also Factor_e_Farm_Infrastructure_Buildout_2011

See also

Instructions At This Stage

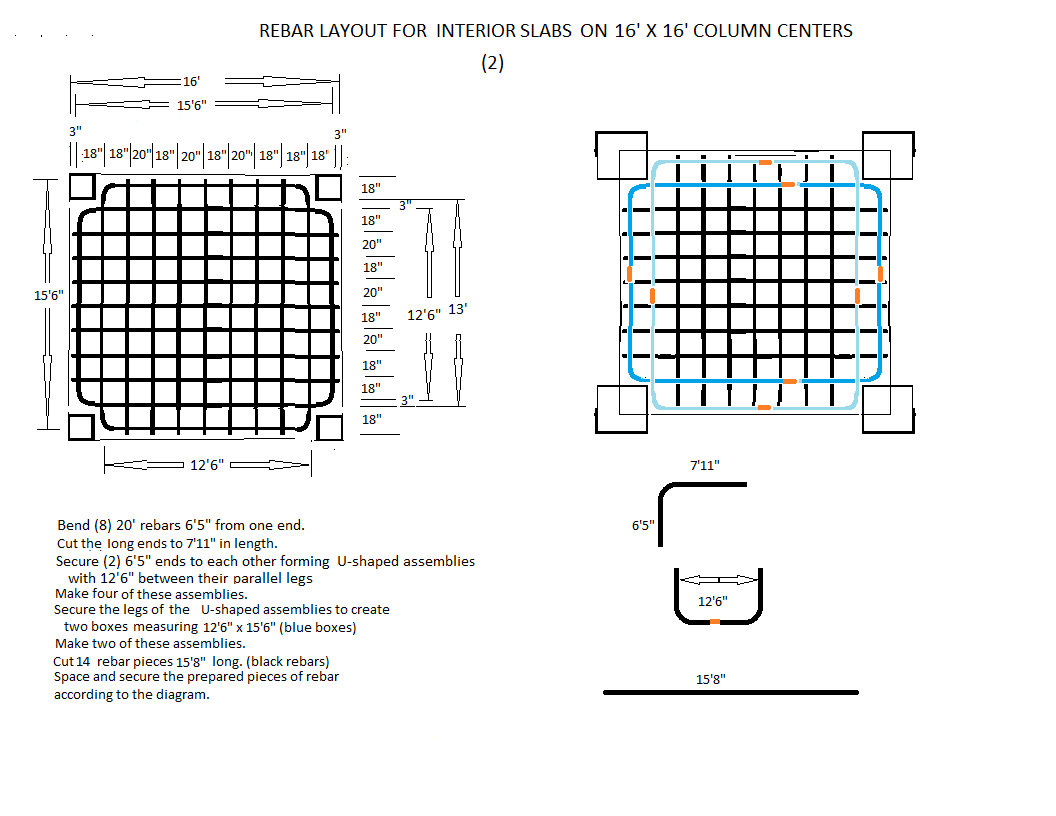

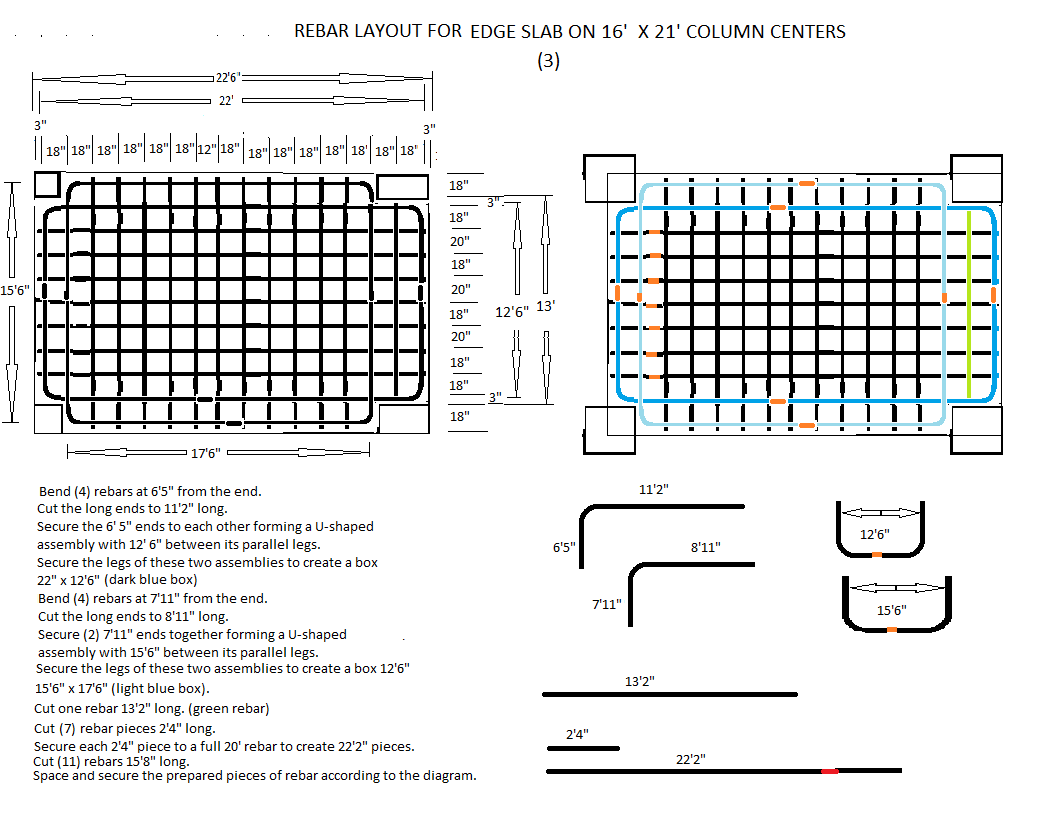

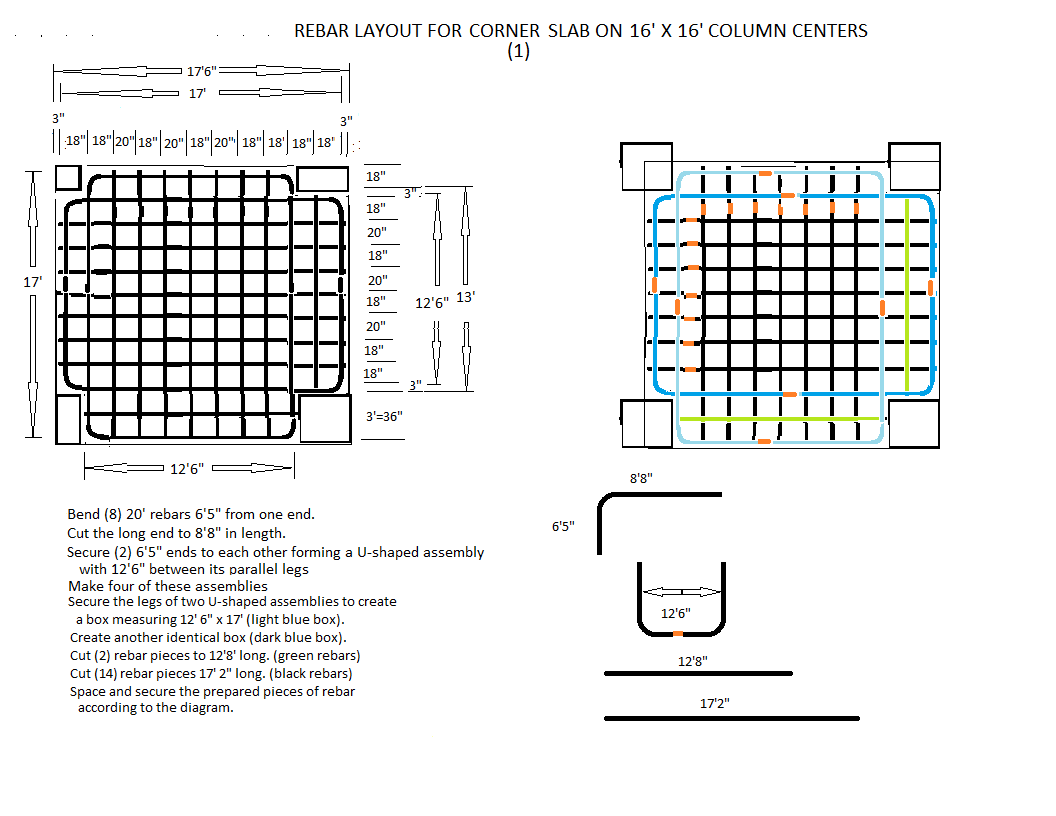

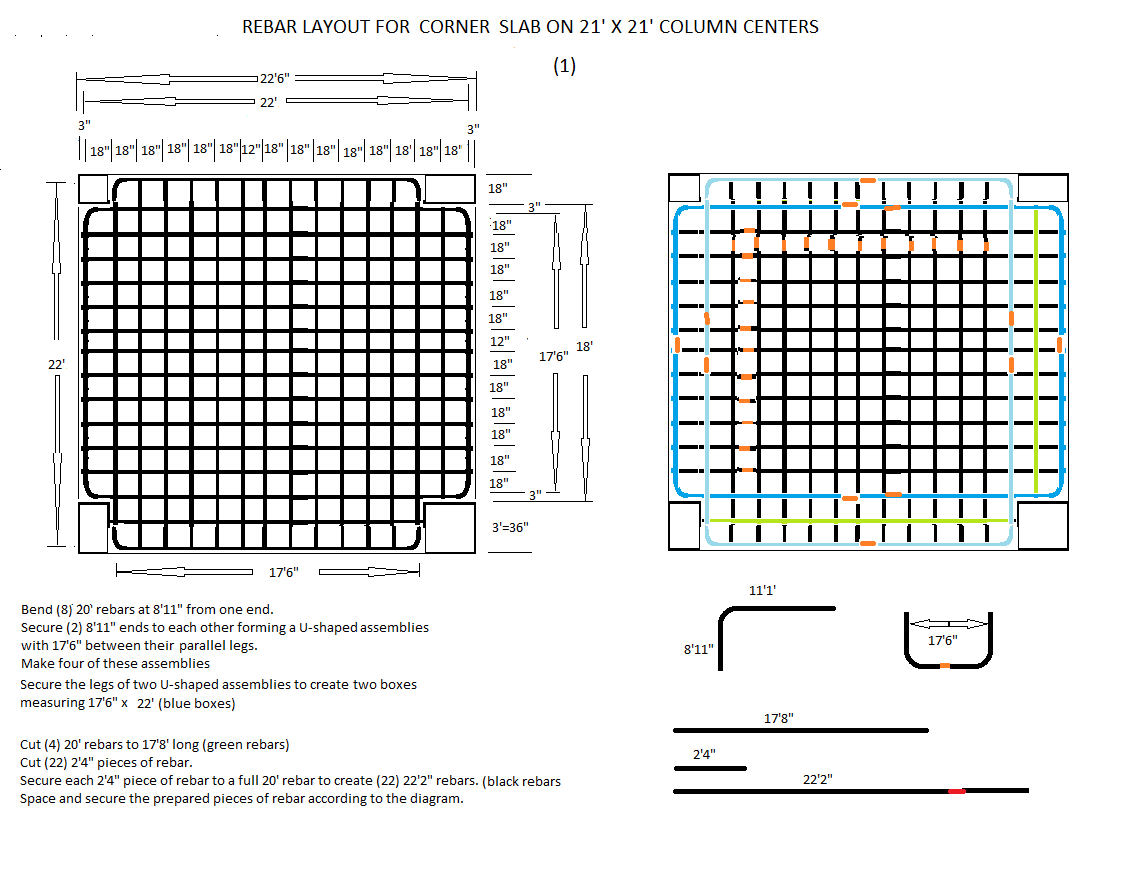

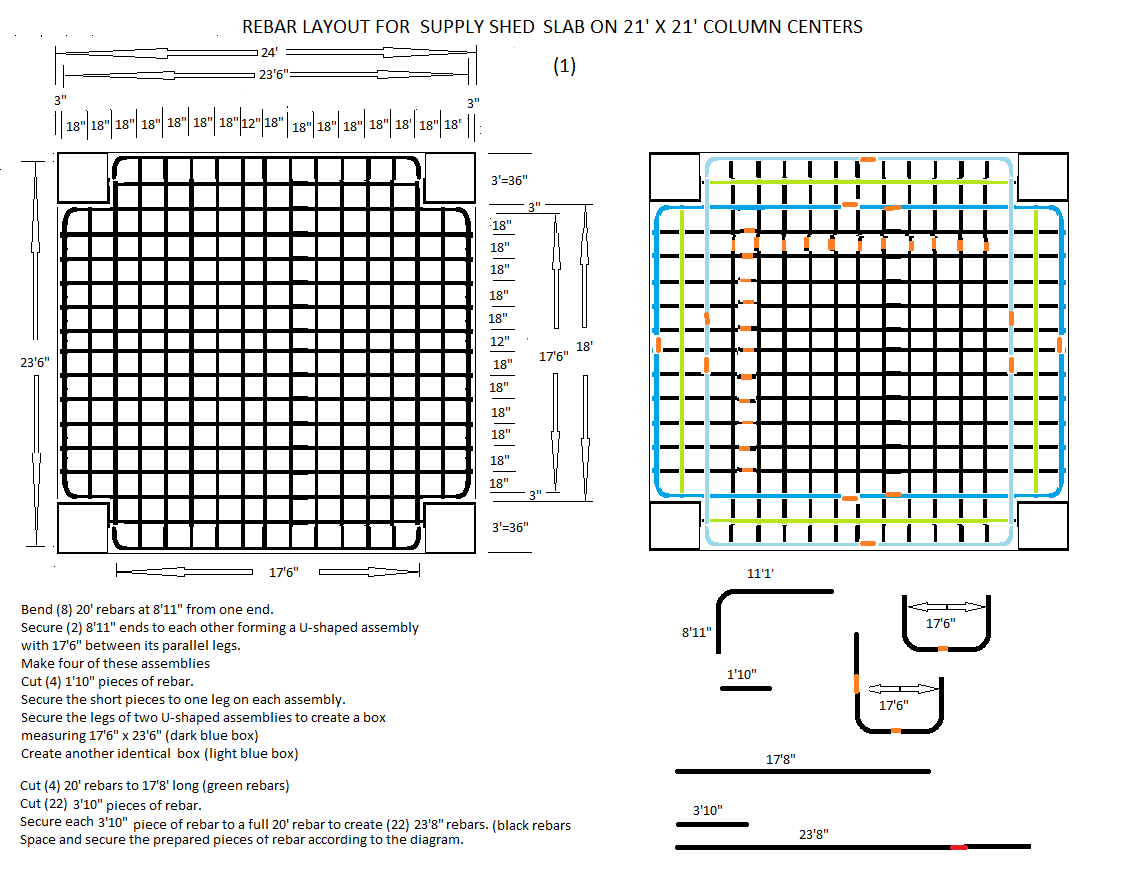

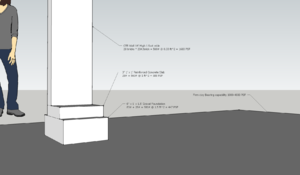

[Rebar plan for column footings]

[Excavate and fill column pad holes]

[Assembly sheet for column pad forms]

[Excavate and fill column pad holes]

[Detailed stakeout of building plan]

Future Instructions

Design Model

Youtube quick Tour here [http://www.youtube.com/watch?v=gsowoMjSy2I]

Sketchup model: [http://sketchup.google.com/3dwarehouse/details?mid=461634956aef7a94d79276599ab9c72d]

Embed:

Notes for model update

- put tie detail into model for roof beams to roof boxes

- create rebar plan

- reset animation points after model rotation

- generate new animation and walkthrough

- upload to youtube and update wiki

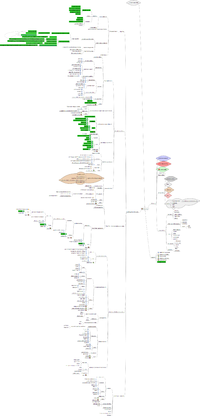

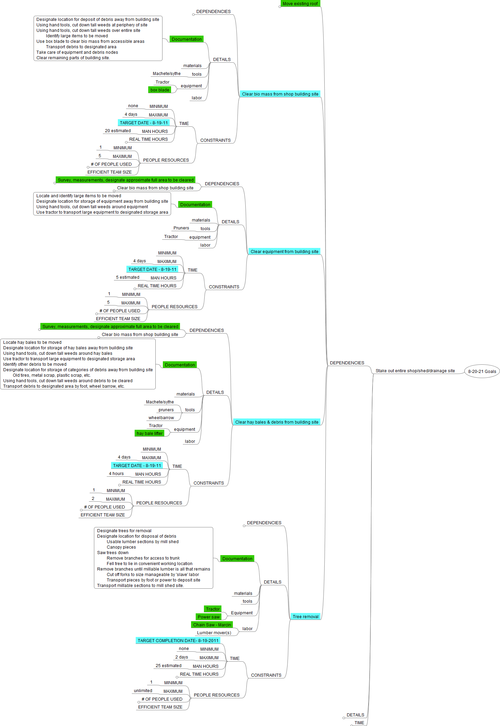

Construction Plan Mindmap

Full size here:[[1]]

Actual Mindmap file here (created with freemind) [[2]]

Supply sources

Sand & Gravel - Larry McFee - Maysville - 816 724-0736

Cost Estimates

Also see Factor_e_Farm_Infrastructure_Buildout_2011

Materials and Budget

- 4 Milwaukee cordless drills - $407

- Roof metal - 136 panels, 17' long (3' widths) - 108 for workshop, 22 for material shed, and 6 extra + flashing for clerestory + screws + flashing closure - total $5871

- 2x6 lumber, $6.60 - total 396 pieces - total $2802

- Glue, #25 star driver bits, 3" star bit screws, 2 glue guns, furring strips, 2 tie downs - $299

- Trailer rental for lumber - $47

Design Notes

Loading Dock

Add a loading dock for easy access to truck bed level deliveries

Driveway

Improve and expand the driveway to be smoother, wider, and double-access (pull-through) and have designated parking spots.

Equipment Room

Build an equipment room in the storage shed.

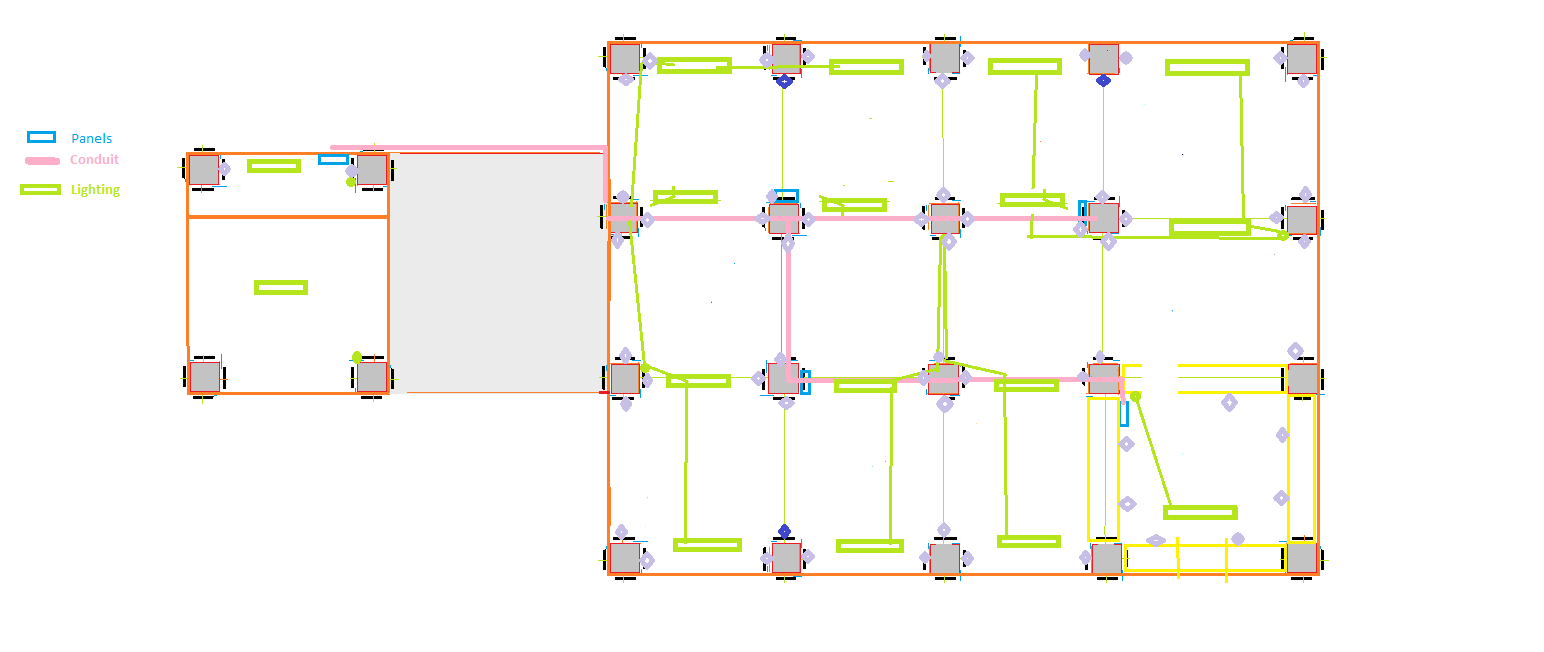

This will keeps the noise of the compressor, generator, hydraulic pump, and such away from the shop. Will also provide storage for smaller parts. Piping and conduits carry power in various forms into the shop.

Expand Shop

- Moved both last rows of columns out 7.5 feet

- Very moderate cost for 500 additional square feet of space

- Simplifies roof plan.

Storage/Equipment shed on south end

Between the shop and the berm

Use 2x6

2x6's cost *half* of what 2x10's cost. We're spending almost $3000 on lumber. Can we save $1500?

This calculator externally:

Indicates that 2x6's can be used for our spans easily if our snow load is less than 10 pounds per square foot (about a foot of snow), and probably are even okay for 10 pounds per square foot.

It is my judgement that at least shifting to 2x8's to save cost would be worthwhile. 2 x 6's will work fine, the vast majority of structures use them.

Technical Notes

Roof Tie

The use of Simpson Strong Tie model 2.5 can bind the roof panels to the rafter boards in such a way as to bind the roof to the rafters. We will use 100 of them, tying all of the edges and middles of the roof boxes to the rafters.

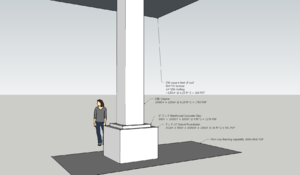

Foundations

The site is a heavy clay soil with a calculated bearing capability of between 1000 and 4000 pounds per square foot. The foundation design goal is to bring the building static load below 1000 PSF, so that the possible live load (gantry crane loaded, snow on the roof) even doubling the load will keep the foundation pressure beneath 2000 PSF.

Work documentation

How to make a water level: http://www.youtube.com/watch?v=nAcT_1T25LM

How to lay a brick: http://www.youtube.com/watch?v=lORIZ1shRIM

Instruction pages for each step of the project are being prepared and will be posted periodically as time and availability allow.

Earth Compaction

See Earth Compaction