OSE Shop 2011/OSE Mill Shed 2011

In order to build the proposed work shop, an existing roof structure had to be moved. Rather than tear it down completely, it was decided to put it to use to cover an area that would most likely be used to house milling equipment for preparing boards from native trees. This page contains information about how that project is to being accomplished.

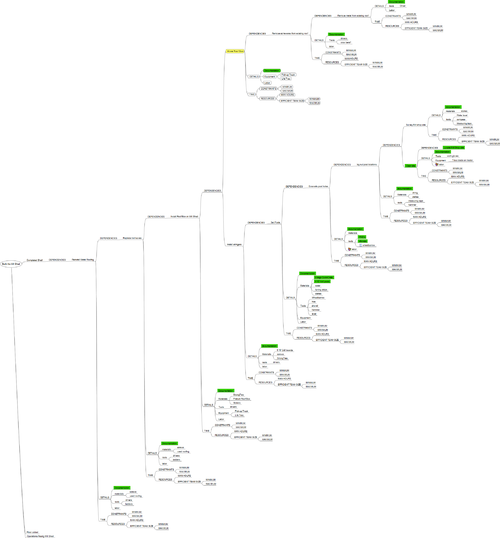

Mind Map

The planning for this part of the project was done with a FreeMind mind map.

Documentation-Assembly Sheets

Mill Shed building instructions

Clear Mill shop site

- Verify with site leader (Marcin) location

- Identify material to be cleared

- Designate deposit location for cleared material

- Move debris from site to waste site, sorting into categories as appropriate

- Clear vegetation

Survey and Level Mill Shop Site

- Use water level and tape measure to determine site slopes

- Scrape and fill to even out floor space.

- If filling, tamp the fill to compact and level it.

Prepare Pre-built roof for moving

- Remove metal roof panels: Remove and stack wooden edge weights.

- Remove screws holding metal panels in place.

- Remove and stack metal panels near reassembly area

- Remove eaves assemblies.

- Remove screws holding designated eaves to main frame.

- Relocate removed assemblies near reassembly area

Move Pre-built roof from present location

- You may want to protect the finish of the pickup truck’s bed walls with pieces of carpet or blanket.

- Station helpers along one prepared edge to lift frame onto pickup truck bed walls.

- Back pickup into position

- Lift frame to height of pickup bed and back pickup under frame.

- Rest frame on walls of pickup bed.

- Position Fork Lift on opposite side of roof frame and lift the frame off the posts it is resting on.

- Coordinate truck and fork lift movements to traverse the necessary distance and orient roof box with cross beams perpendicular to slope of roof.

- Station helpers around frame and lower frame off pickup truck

- Temporarily cover frame with roof panels for overnight protection

- Locate prepared roof box on ground at surveyed location.

Lay out post locations

- Mark post locations at the inside corners of the roof frame

Excavate post holes

- With an auger or a post hole digger, dig out marked sites for post holes to 3 feet deep x 12” diameter on the high side of the roof.

- With an auger or a post hole digger, dig out marked sites for post holes to 4 feet deep x 12” diameter on the low side of the roof.

- Deposit removed dirt in depressions within the shop site.

- Tamp down loose deposited dirt for a firm floor.

Set Posts

- Gather supplies and tools

- Mix two bags of concrete (see how far it goes)

- Put 2” of concrete in base of one post hole

- Put 4x4 post into hole and fill around it with concrete until slightly over full

- Eliminate air pockets in the concrete as much as possible by vibrating the shovel or tamping

- Check perpendicular with level on two adjacent sides

- Brace post in place with furring strips and stakes

Prepare the Posts

- Measure and cut pole heights to provide for rain run-off in the best direction.

- Low side poles should be 1 foot lower than high side poles

- The tops of the poles on the low side and the tops of poles on high side of the building should be level with each other.

- Near the top of the posts, screw 16’ pieces of 2x6 across the inside faces of the high side posts and the low side posts (for stability during roof raising).

- Screw scrap piece of wood 5-1/2” below top of each post on inside faces of all four posts.

Raise the Roof

- Raise North edge of roof box with fork lift.

- Attach supporting scrap pieces of lumber on East and West outside faces of North posts.

- Raise South edge of roof box with fork lift.

- Attach supporting scrap pieces of lumber on East and West outside faces of South posts.

- Repeat steps these four steps until Roof is near top of posts.

Install Stringers

- Raise the low edge of the roof box with fork lift above height of posts.

- Using the scrap on the inside faces for support and location, attach a 16’ 2x6 to the posts.

- Screw scrap piece of wood 5-1/2” below top of each post on outside faces of these posts.

- Using the scrap on the outside faces for support and location, attach a 16’ 2x6 to the posts.

- Lower the roof edge into place.

- Repeat the last five steps on the high side of roof.

- Secure roof box to stringers with Strong Ties and screws.

Replace eaves assemblies removed for transport

- Place Pickup or scaffold for height

- Use 2 people to position and support eaves assembly.

- Reattach eaves assemblies to roof frame with new screws.

Reinstall Metal Roofing

- Place Pickup truck or scaffolding to allow workers to access roof area.

- Install metal roofing panels starting with South panel. (winds come more often from the north than from the south.)

- Use screws with weather-proof washers.

- Lap North panels over South panels.

Finishing Details

- I would suggest looking at the drip-line of the roof and making arrangements to catch or at least channel storm run-off.

- I would also suggest at least a leveled floor/work area.

- If you are going to collect and recycle sawdust, a vacuum collector will be needed if you don’t pave the floor.

- In this NW Missouri climate, at least North and West weather protection should be considered.

Materials and Time Report

Dollar costs for this project were minimal since we recycled a previously built roofing unit. Purchases specific to this project included: 4 Posts 4" x 4" x 12' 8 bags of QuickCrete 4 Stringers 2" x 6" x 16' Approximately 150 3" deck screws 4 StrongTie brackets

Time used for this project: A volunteer service crew of about 10 from the local Church of Jesus Christ of Latter-Day Saints completely cleared the site of a large pile of scrap wood and a variety of farm debris in about one hour = 10 man-hours. Moving the roof used a crew of 7 on-site workers (not all of them all of the time)and was accomplished in about 5-1/2 hours = about 20 man-hours. Digging the post holes with manual post-hole diggers took about 2 man-hours. At this writing, the concrete has not yet been set nor the roof raising completed.