3D Printed Stepper Motor

480 Step Per Revolution Nema 17 by David Hartkop

- https://www.thingiverse.com/thing:1362555 - amazing work

- https://www.ideapropulsionsystems.com/david-hartkop-resume

- More about split-ring, compound planet gears - [1]

- Concept of split annulus gearbox or split annulus planetary gear - which gets a very large geardown in a super compact form factor - much improved over the stacked planetary gear!!!! Game changer for high torque, low speed applications.

- See example at Hackaday - [2]

- Is this the same as Strain Wave Gear?

Communications

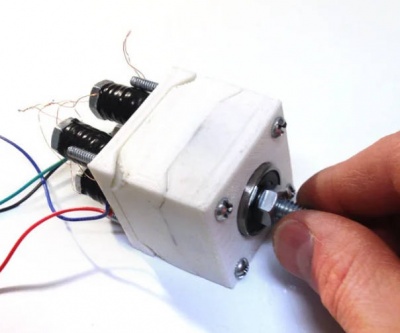

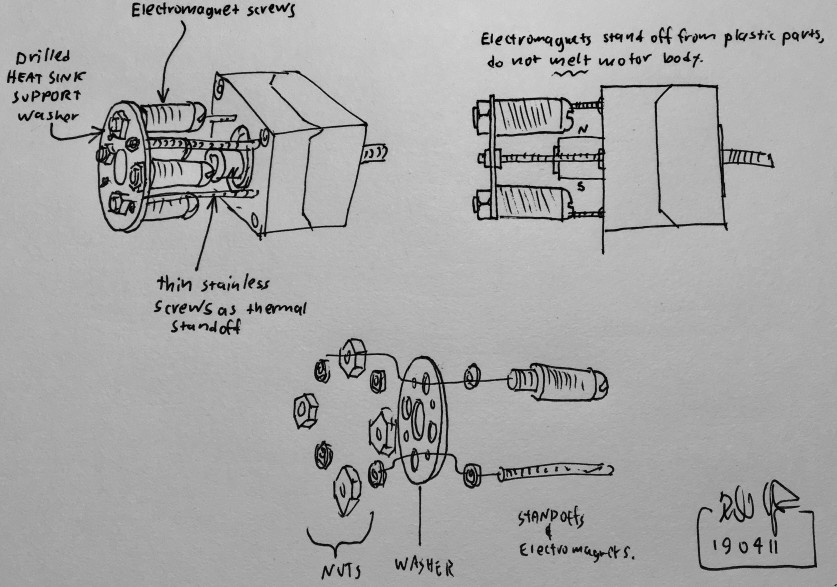

Marcin, Thank you! I have actually made some strides in designs for 3d printable stepper motors since then, but have not had a chance to publish anything. The main advancement in that 3d printable stepper design has to do with thermal management; the wound-screw electromagnets tend to get so hot they start melting out of the holes in the motor. If you are going to build a set of them for your camp I recommend setting it up with the electromagnets on a washer being used as a standoff, see attached picture from sketchbook ;-D

Also, I didn't have a very good grasp on how to figure out the gear tooth pitch when I made that stepper motor. There is a spreadsheet I made for figuring that all out, attached to the split ring compound planet GitHub: https://github.com/IdeaPropulsionSystems/CoolEpicyclicGearing/tree/master/GearSpreadsheets

Downloaded: File:EpicyclicGearCalc Hartkop.ods

It might be overkill, but it at least lets you calculate it correctly. The pitch difference for doing this split ring thing with 60 teeth is so small you can literally 'wear-in' the pitch by just forcing it to turn with a drill for like 5 minutes, which is what I was doing.

I'll check out your TED talk. That's awesome. Please let me know any way I can be involved in some things that you do. I've been developing some open source humanitarian things, one being an open source medical autoclave. https://www.ideapropulsionsystems.com/idea-propulsion-systems/openautoclave

Best wishes, Sincerely, David Hartkop. :-D